Ferrari's symbolic, Italian crafter making V-type 12-cylinder engine

Ferrari's612 ScagliettiHas secured a residential space by increasing the size of the body, was placed lowV12 engineIt is exactly creating a ride comfortable to the name of "Grand Tour", a dry presenter of TV program "TopGear" dealing with topics on British cars,Jeremy ClarksonAlso"After seeking the best car, after that, next ride is 612 Scaglietti"To praise it. How is the engine that supports this high performance made? Let's see a movie that collaboration with the latest machine and craftsman's manual work.

Details are below.

In Ferrari, basically one engineer is in charge of checking each process from the beginning to the end of the assembly of one engine. Although you can understand by watching a video, if you simply say check it will be enormous, so you do not know how much trouble it will take.

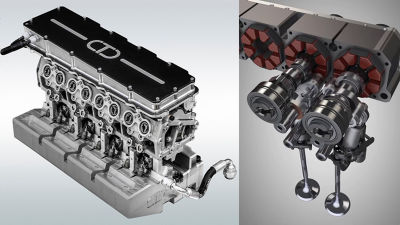

This is Ferrari · 612 Scaglietti's engine "Tipo 133E". With a bore 89 mm × stroke 77 mm, it is a long stroke in the same series of engines, with a maximum output of 540 PS at 7250 rpm. If it is the current moped, is it about 180 cars?

YouTube - Ferrari V12 Engine

The engine making begins with melting the ingot.

Heat it in a blast furnace until it becomes mushy.

After melting, remove the trash.

Making sand mold.

Fine modifications are done manually.

Preparing for casting with molds.

I will pour the molten metal here.

Here also manual work.

Pull out the mold

An X - ray examination is carried out and a check is made to see if cracks are running inside.

Also check the inside of the port one by one with the endoscope.

Ferrari engine factory. Contemporary engines are on exhibition.

The inside of the factory is a bright space where plants were arranged.

Cutting while applying oil to reduce friction.

The head surface is also polished.

We will finish the crankshaft, an important part that turns the longitudinal movement of the piston into rotational motion.

Then quench.

Port finishing is also manual work.

Press fitting of a metal ring called a valve seat that receives intake and exhaust valves.

Insert a slightly shrunk valve seat into the port, chilling down the kinkin. When temperature returns, it expands and does not come off. Although it is a simple work, it is thought that it is a tremendous effort when it comes to the total 48 valves.

Polishing the combustion chamber. Experience is needed because the slight difference in finishing is also the part that appears in the performance.

Once the assembly is completed, it is wrapped and brought to the body factory.

Connecting rod connecting piston and crankshaft. Total 12 pieces.

Insert the quenched crankshaft.

Insert the piston into the cylinder.

Move slowly and work together.

DOHCSo the camshaft consists of two banks, one in total.

It gradually became an engine shape.

Assembling the exterior.

Each process seems to be recording the person in charge with the ID card.

Beauty that you want to decorate as it is this way.

Operation test with engine alone.

I am moving at a considerable number of revolutions.

The exhaust pipe burns red. Is it good for testing?

This completes the engine.

I will install it on the car body.

Even after putting it, I still have a test.

Even if painting is finished, the person in charge checks to the end.

It is finished just finishing so far.

Related Posts: