An engineer who made his own espresso machine by being too addicted to espresso is publishing its development process

Espresso can be extracted by ``pouring hot water close to 100 degrees Celsius into finely ground beans and applying a very high pressure, almost nine times the atmospheric pressure''. However, a special espresso machine is required to apply high pressure. Eric Chan, a product design engineer at Meta, publishes the development process of his own espresso machine on his blog.

Four Bar Design: DIY Espresso

There are many coffee lovers in Mr. Chan's workplace, and many coffee makers including espresso machines are installed. Mr. Chan didn't know the difference between espresso and coffee at first, but as he learned how to brew espresso, he understood the basics of extraction, the type of beans, and how to grind. is.

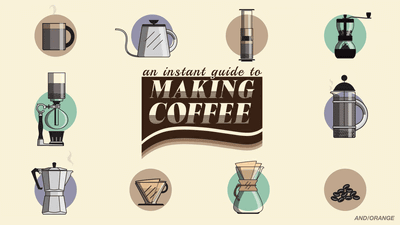

But with the coronavirus pandemic driving more work from home, 'I realized how much I missed espresso,' Chan said, because he didn't have an espresso machine at home. So, he bought a coffee grinder from a friend, bought beans at a coffee shop, and brewed coffee using a colander and a cheap coffee filter.

Next, Mr. Chan got 'AeroPress' which brews coffee with the power of air. You can understand what kind of coffee maker AeroPress is by reading the following article.

Also, by purchasing tools such as pottery drippers and Melitta coffee filters, he was able to brew coffee at a level that could be served to guests. However, they all brew coffee, not espresso. However, since the espresso machine is very expensive, Mr. Chan seems to have come up with making his own espresso machine.

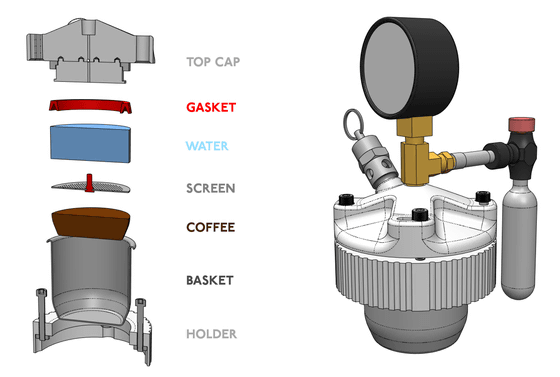

Mr. Chan devised a method of using compressed gas with his own espresso machine to create a high pressure of about 9 atmospheres. The idea is to use a small, inexpensive soda cylinder to generate the pressure needed to brew the espresso, rather than pushing down a big, long lever.

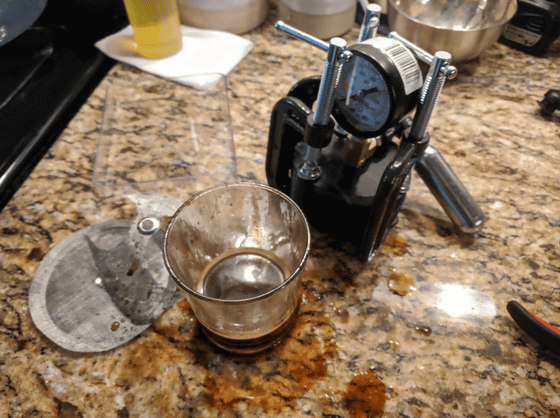

However, when Mr. Chan assembled the parts purchased by mail order and the cap output by the 3D printer and put espresso in immediately, he said that it ended in a big failure at first. Although something like espresso was extracted for the time being, when I drank it, it was just a dark coffee, it seems that it was not so much as espresso. That is, it is expected that not enough pressure was applied.

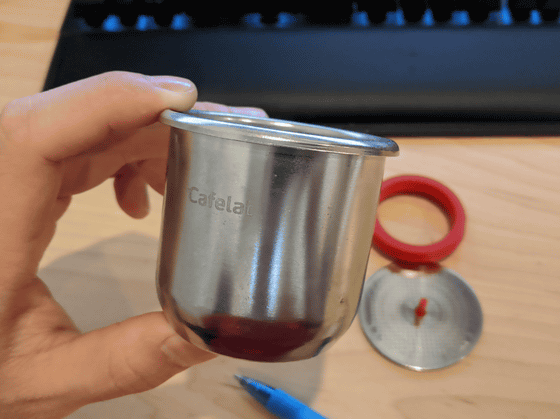

Therefore, Mr. Chan purchased a filter basket for receiving bean flour and filters for espresso for $ 25 (about 3600 yen) to start making his own espresso machine No. 2.

In addition, we reviewed the structure again, and instead of using a 3D printer, we commissioned an overseas supplier to machine stainless steel for the fixture that holds the filter basket. All stainless steel parts are quite cheap at only $ 102 (about 15,000 yen), Mr. Chan said, ``If it was an American vendor, it would have cost at least four times this.'' I'm here.

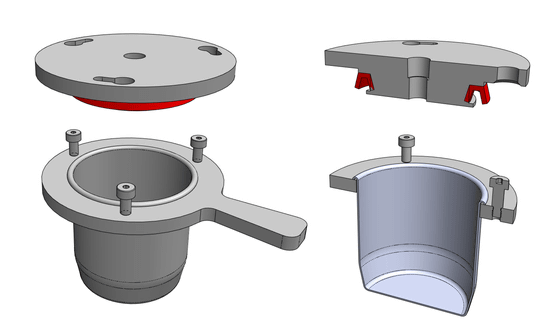

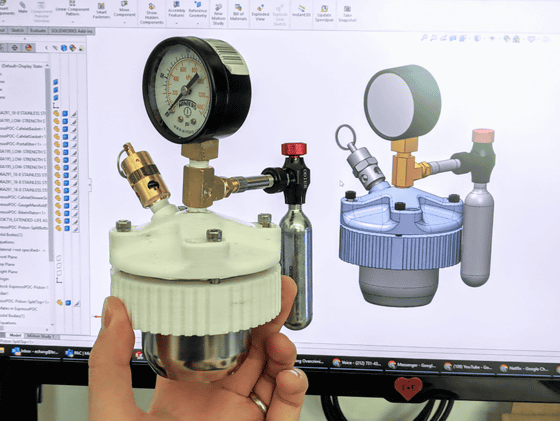

The following is the espresso machine designed by Mr. Chan, repeating the prototype many times. The filter basket containing coffee, filter and hot water is fixed with a cap (TOP CAP) and a holder (HOLDER) and screwed. A carbonic acid cylinder and a pressure gauge are attached to the cap.

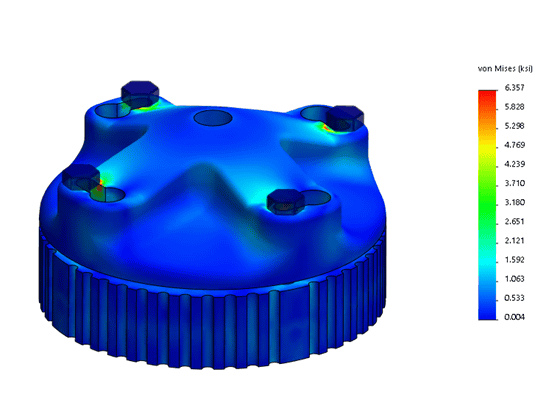

He said that he repeatedly verified by simulation so that the parts would not break even if strong pressure was applied.

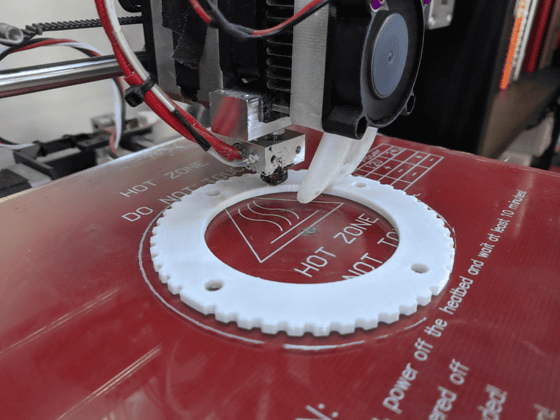

Output the cap and holder by yourself with a 3D printer.

The assembled and completed espresso machine is below.

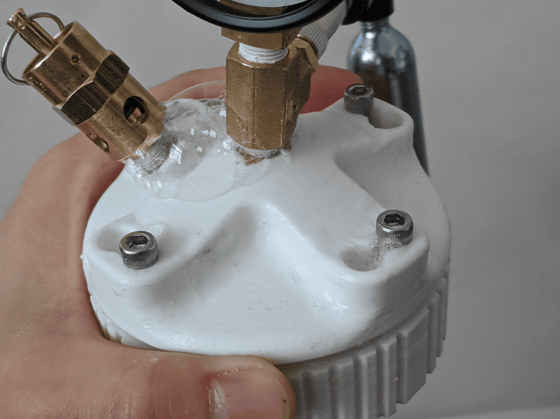

Espresso machines apply a lot of pressure, so good sealing is important. When Mr. Chan put soapy water and applied pressure to check the airtightness, he said that soap bubbles overflowed from everywhere. Therefore, Mr. Chan seems to have been forced to redesign in order to increase the accuracy of the parts.

After repeated checks, the fully sealed espresso machine was finally completed.

You can actually see Mr. Chan brewing espresso with his own espresso machine in the following movie.

DIY 3D Printed Espresso Machine-Workflow Demo-YouTube

The place where espresso is extracted from the filter basket is like this. It seems that about 2.6 g of carbon dioxide gas is consumed in one extraction, and the cost is 0.15 dollars (about 22 yen) per cup.

DIY Espresso-Slow Motion Extraction-YouTube

Mr. Chan said, ``I am quite satisfied with the results, but there are still many things to improve,'' and how the carbon dioxide gas for applying pressure melts into the espresso and affects the taste. He argues that there is still room for improvement, such as unknowns and whether carbon dioxide consumption can be further reduced.

In the future, Mr. Chan plans to release the 3D data of his own espresso machine and distribute the necessary mold parts for a fee.

Related Posts: