The latest battery factory for electric vehicles is evolving into a more environmentally friendly factory by recycling old batteries

The battery is the most important part of electric vehicles, which are becoming more and more popular around the world. At the latest electric vehicle battery factory, the economic newspaper The Economist summarizes that environmentally friendly efforts such as recycling old batteries and manufacturing new batteries are being carried out.

Gigafactories are recycling old EV batteries into new ones |

In the future automobile industry, electric vehicles and their main parts, batteries, will occupy a very important position. Therefore, countries with a thriving automotive industry are making various efforts to successfully attract factories that manufacture batteries for electric vehicles. It seems that the battery manufacturing factory for electric vehicles is often called the Gigafactory, following the coined word 'Gigafactory' for the battery factory in Nevada, USA, which Tesla jointly built with Panasonic in 2014.

There is also the latest Gigafactory in Vastellas in the western part of Stockholm, the capital of Sweden. The factory, with workers dressed head-to-toe in sterile white suits behind airlock doors, looks more like a pharmaceutical lab than an electric car battery factory. It looks like

This Gigafactory is the factory of Northvolt, a Swedish battery manufacturer founded by two former Tesla executives. This Northvolt factory is called Gigafactory's 'model factory', and unlike factories that purchase battery parts such as electrodes from other manufacturers, it can manufacture all the parts required for electric vehicle batteries. It is said that the facilities are in place. The Northvolt plant develops battery cells for new vehicles under development by customers such as Volvo Cars, BMW and Volkswagen. It seems that these manufacturers will design and manufacture the batteries of the prototype vehicles used for testing, and the batteries that have cleared the test will be mass-produced at a larger battery factory.

Northvolt plans to build a second Gigafactory in Gothenburg, Sweden in a joint venture with Volvo Cars, and is also building a Gigafactory in Germany separately. Furthermore, it aims to reach a total annual production of 150 GWh by 2030. If this happens, Northvolt's Gigafactory alone will be able to produce 2 million electric vehicle batteries per year. It's also worth noting that Northvolt's Gigafactory plans to recycle about half of the lithium, cobalt, nickel, manganese, and other materials that make up its batteries. If Northvolt can achieve this ambitious goal, it will be a big step toward a 'circular manufacturing industry' that will lead to a significant reduction in environmental impact, according to the economic newspaper The Economist.

In a lithium-ion battery, one electrode, the negative electrode, takes electrons from lithium atoms to generate ions, which move through the electrolyte and move to the other electrode, the positive electrode. On the other hand, the electrons go through the external circuit to the positive electrode, which in the case of an electric vehicle supplies power to the motor. The ions and electrons then recombine at the positive electrode, connect to a charger, and stay there until the process is reversed.

The positive electrode accounts for about 40% of the cost of an electric vehicle battery. Cathodes are made from a combination of different chemistries, and the difference in composition of these chemistries is a key differentiator in battery technology. Therefore, the chemical composition of the positive electrode is fine-tuned not only for each manufacturer, but also for electric vehicles ranging from sports cars to family cars to large SUVs. A common positive electrode chemistry is a combination of nickel, manganese, and cobalt. Ultra-pure graphite, a type of carbon, is generally used for the negative electrode. In addition, other substances may be added to either electrode to stabilize the active material or adjust its performance.

The active material is immersed in a suspension, the material used for the positive electrode is applied to aluminum foil, and the negative electrode is made by spreading graphite over copper. The aluminum foil is then dried in the oven, pressed and rewound. At Northvolt's Gigafactory, battery cells are created by sandwiching positive and negative electrodes between an electrolyte solution containing lithium and a membrane called a separator. By providing a membrane called this separator, it seems that it is possible to prevent the electrodes from contacting each other through lithium ions and shorting the battery.

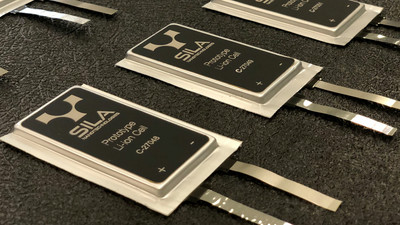

This battery cell is the basic unit of a lithium-ion battery. Next, we move to the process of packaging the created battery cells, but ``There are various ways to do this,'' The Economist points out. Commonly used are “square” cell modules, which incorporate dozens of battery cells in an aluminum enclosure, depending on the vehicle's power requirements.

After finishing the packaging, the battery modules should be tested. Modules that are judged to be good will be shipped directly to automakers and installed in electric vehicles or used for industrial applications such as grid balancing at Northvolt's factory in Gdansk, Poland.

At Northvolt's Gigafactory, used batteries are collected and then disassembled into raw materials for the positive and negative electrodes, the first stage of production. ``The method of dismantling the battery, crushing the cell and turning it into a powder called'black liquor'is being improved day by day by robots,'' said Emma Nehrenheim, Northvolt's environmental officer.

Northvolt's use of Sweden's abundant hydro and wind energy, as well as its increased use of recycled and renewable energy, will reduce the raw materials needed to manufacture its batteries, as well as the carbon footprint generated by mining and transporting them. I claim that I can.

However, not all recycled batteries become material for new batteries. For example, although graphite can be used in water purifiers, it cannot be used as a material for new positive electrodes. That's why Northvolt is working with Finnish wood products company Stora Enso to explore greener alternatives. ” is being developed.

Even more troublesome is the case where there is a problem with the source of raw materials. For example, much of the cobalt used in battery cathodes comes from the Democratic Republic of the Congo, where child labor is used in much of the mining operations. For that reason, Northvolt and other battery makers are trying to deal directly with mines to avoid purchasing raw materials from producers who use child labor. This will make it easier to track the origin of raw materials and make it easier to check production standards.

Northvolt is not the only company working to make battery manufacturing a circular manufacturing industry. CATL, a major manufacturer of electric vehicle batteries in China, has expressed the view that the carbon footprint of battery manufacturing can be reduced by using renewable energy, recycling battery materials, and improving production processes. We are working to introduce measures to use hydroelectric power as a power source at our 10 factories.

Related Posts:

in Vehicle, Posted by logu_ii