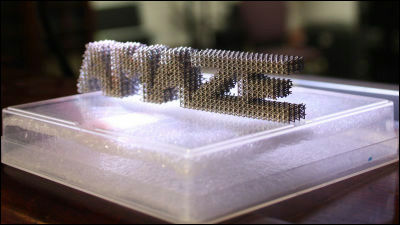

A method of 3D printing will be developed while maintaining the characteristics of stainless steel that is resistant to corrosion and strong

In recent years, with the development of 3D printing technology,

Phase transformation dynamics guided alloy development for additive manufacturing - ScienceDirect

https://doi.org/10.1016/j.addma.2022.103068

Researchers Uncover How to 3D-Print One of the Strongest Stainless Steels | NIST

https://www.nist.gov/news-events/news/2022/09/researchers-uncover-how-3d-print-one-strongest-stainless-steels

17-4 PH stainless steel is a type of stainless steel named for its chromium content of about 17% and nickel content of about 4%, and is characterized by its resistance to corrosion and high strength. Therefore, 17-4 PH stainless steel is widely used in ships exposed to salty seawater, the nuclear industry, the paper industry, and other precision machinery parts.

Metal 3D printers typically weld a layer of metal powder or melt and layer the metal, which rapidly cools the metal in the process. It seems that this extreme temperature change can shift the atomic arrangement in the material, change the crystal structure, and lose the original characteristics of the material. The key to the properties of 17-4 PH stainless steel is the martensite structure obtained by rapid cooling of the alloy.

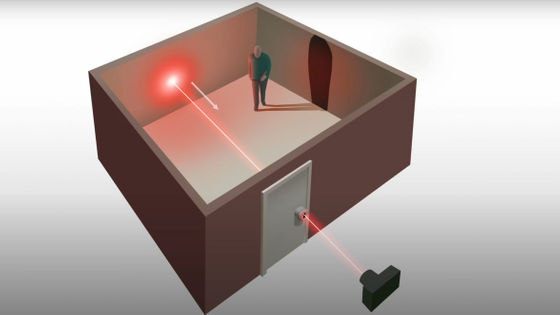

Therefore, the research team analyzed changes in the internal structure using a technique called synchrotron X-ray diffraction (XRD) to clarify what happens with temperature changes during metal 3D printing. Lianyi Chen, one of the researchers involved in the development, explains, ``In XRD, X-rays interact with the material and form a fingerprint-like signal corresponding to the material's unique crystal structure.'' .

The research team used the Advanced Photon Source , a high-energy X-ray light source facility at Argonne National Laboratory, to map the changes in crystal structure in 17-4 PH stainless steel during 3D printing, revealing that controlling factors such as the composition of the powdered metal are involved in the process. We analyzed the overall impact.

Experimental results show that by controlling the composition of stainless steel, including iron, nickel, copper, niobium , and chromium, it is possible to 3D print 17-4 PH stainless steel while maintaining the properties of conventionally produced stainless steel. . Furthermore, in some compositions, 3D printing alone enables the formation of strength-enhancing nanoparticles that previously required cooling and reheating of the steel. The 3D-printed 17-4 PH stainless steel was confirmed by mechanical testing to be as strong as conventional 17-4 PH stainless steel.

“Controlling the composition is key to 3D printing alloys,” said Fan Zhang, a physicist at NIST. demonstrated that cooling rates over a wide range of 10-10 million degrees Celsius per second resulted in 17-4 PH stainless steels that remained consistently martensitic.'

An XRD-based approach to analyzing crystal structure during 3D printing could also help optimize 3D printing in alloys other than 17-4 PH stainless steel and develop computer models to predict the quality of 3D printed materials. It is said that there is a sexuality. “The 17-4 PH stainless steel we make is highly reliable and reproducible, lowering the hurdles for commercial use,” Chen said. It should be able to print out 17-4 PH stainless steel.'

Related Posts:

in Science, Posted by log1h_ik