A method to convert coal powder into graphite using a microwave oven is developed

Converting raw coal powder into graphite nano-graphite by metal-assisted microwave treatment --ScienceDirect

https://www.sciencedirect.com/science/article/pii/S2352507X20301281

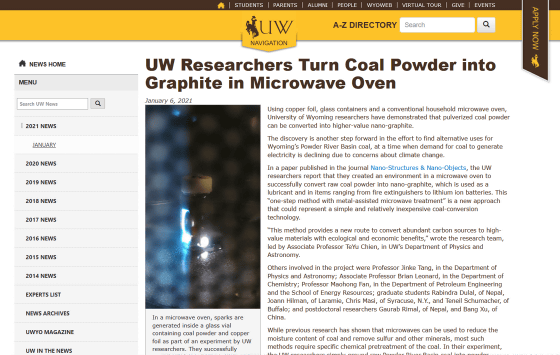

UW Researchers Turn Coal Powder into Graphite in Microwave Oven | News | University of Wyoming

http://www.uwyo.edu/uw/news/2021/01/uw-researchers-turn-coal-powder-into-graphite-in-microwave-oven.html

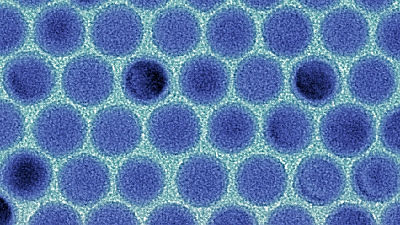

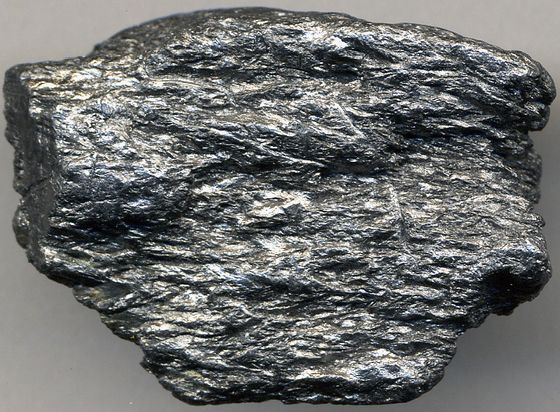

Graphite is an elemental mineral composed of

Research on the method of converting coal to graphite has been underway for some time, and the conversion involves 'high temperature environment', ' reducing atmosphere filled with reducing gas that has the property of depriving oxygen', 'catalyst', and ' microwave '. It was identified that factors such as 'radiation of coal' were necessary.

A research team at the University of Wyoming thought that these factors could be met 'in a typical household microwave oven,' and used a microwave oven to turn coal powder that had not been chemically pretreated into graphite. I devised a method to convert.

First, the research team cut a copper foil made by thinly stretching copper into a sheet, cutting it into a fork, and placing powdered coal on it. Then, the copper foil and coal powder were placed in a glass container in a reducing atmosphere with a mixed gas of

When heating was started in a microwave oven and microwaves were radiated, sparks were generated in the glass container, generating a high temperature sufficient to convert coal into polycrystalline graphite, and the coal was converted to graphite. 'By cutting a copper foil into a fork, microwave radiation triggers sparks that generate ultra-high temperatures of over 1800 degrees Celsius within just a few seconds,' said Christoffer Masi, the lead author of the paper. That's why you shouldn't put a metal fork in the microwave. '

In the experiment, the conversion efficiency was investigated by comparing the microwave irradiation time in the range of 3 to 45 minutes, and it was also found that the optimum microwave irradiation time was 15 minutes. The method of converting coal to graphite using a microwave oven seems to be cost-effective, and the research team thinks that by improving this method and scaling it up, it will be possible to produce even higher quality and large quantities of graphite. I will.

Related Posts:

in Science, Posted by log1h_ik