How to DIY a device that produces liquid nitrogen using a thermos or a metal sponge

It is unlikely that ordinary people will use 'liquid nitrogen,' which is liquefied by cooling nitrogen at an extremely low temperature, but there should be some people who have seen it in skin medical treatment.

Homemade liquid nitrogen generator Joule Thomson Throttle

http://homemadeliquidnitrogen.com/

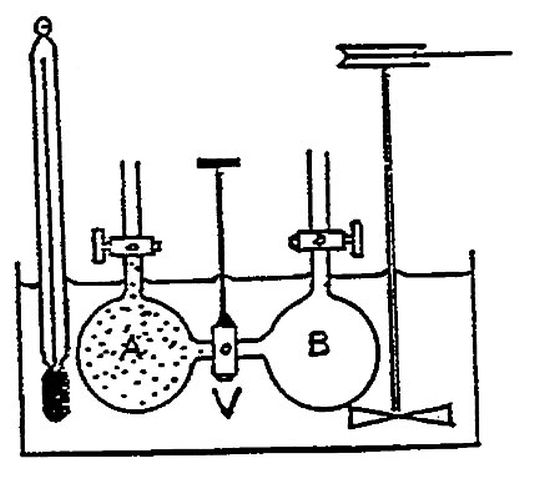

There are three methods to generate liquid nitrogen: 'method using cryogenic refrigerator', 'method using turbo expander ', 'method using Joule-Thomson effect ', and imsmoother adopted It was a method that uses the Jules-Thomson effect. The Joule-Thomson effect is a phenomenon in which the temperature drops when the pressure of gas is drastically lowered through a nozzle, and it is also used for cooling in refrigerators. The theory of producing liquid nitrogen by the Jules-Thomson effect is available in books and the Internet, but imsmoother says that there are barriers to overcome when actually making a generator.

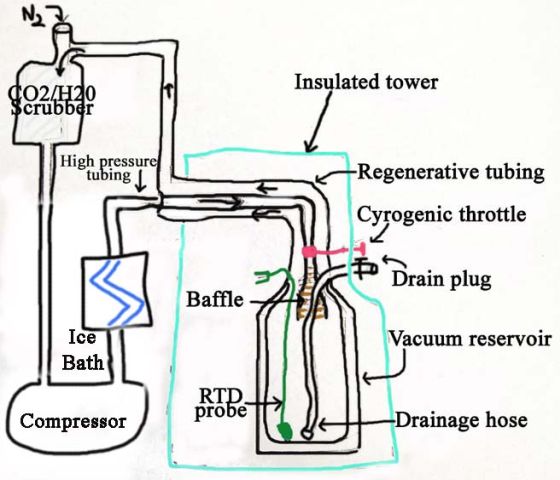

This is an overall view of the liquid nitrogen generator produced by imsmoother. First, the high-melting water and carbon dioxide contained in the gas injected in the “

A

A cooler that cools gas in advance looks like this, and an aluminum plate is attached to a long tube to improve heat dissipation efficiency. It is possible to cool the cooler by submerging it in an ice bath or exposing it to below freezing.

A

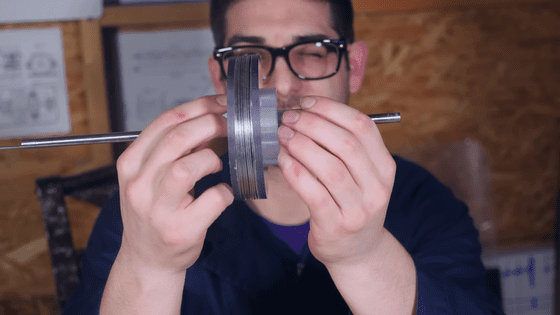

When the gas is cooled by the Joule-Thomson effect, the gas blows out from the cryogenic throttle part. Imsmoother explained that the 'baffle' is the part that slows down the ejection speed of this gas and does not disturb the liquid nitrogen that accumulates on the lower side. Commercially available copper sponge is used for the baffle.

What imsmoother said was the most troublesome of all parts was the 'container for liquefied gas'. The container should be made of a material with minimal heat dissipation and low

Imsmoother thought that it was necessary to make a container with copper, aluminum, and stainless steel in order to withstand a harsh temperature environment, but tried a container made of copper, but the size of the copper container is too large, and heat conduction It turned out that liquid nitrogen could not be kept for a long time because of the high rate.

The container finally adopted by imsmoother was a commercially available stainless steel thermos. When liquid nitrogen was placed in a stainless steel thermos and left for several days, the liquid still remained, and it was found that the loss due to vaporization was low. A

Imsmoother said that the problem of how to prevent heat leakage from the tube was a problem in the regeneration process for carrying the gas that was not liquefied to the cooling process again. imsmoother seems to have prevented the heat leak by covering the tube with

In this way, the cylindrical structure that covers the cryogenic throttle and the regeneration tube and forms the heart of the liquid nitrogen generator is completed.

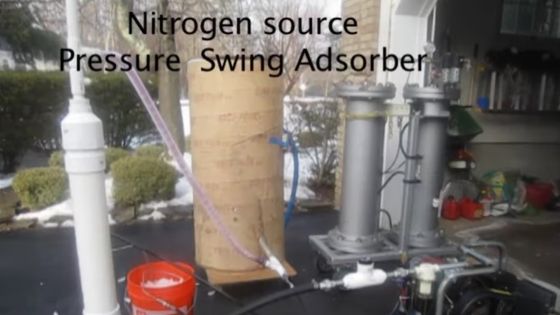

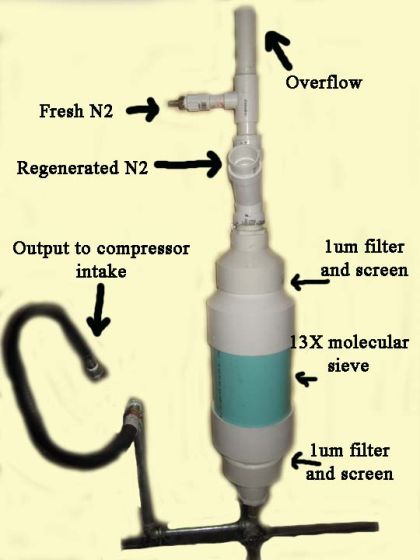

The nitrogen that is put into the liquid nitrogen generator is produced by a device that takes in air and produces nitrogen.

A movie that actually produces liquid nitrogen using this liquid nitrogen generator is released on YouTube.

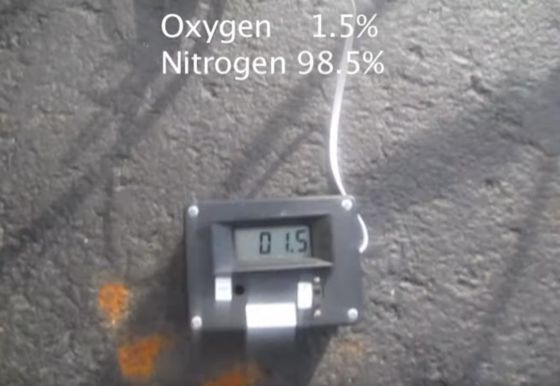

First of all, nitrogen is injected into the device. The gas injected is 1.5% oxygen and 98.5% nitrogen, so it is composed mostly of nitrogen.

Applying pressure with a compressor...

The temperature of the gas drops to an extremely low temperature.

The equipment cooled the nitrogen, and liquid nitrogen came out.

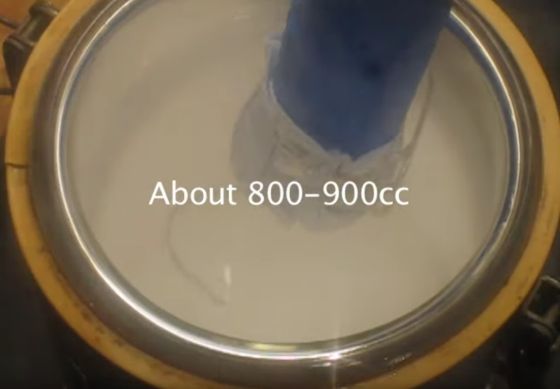

Finally, we have successfully obtained 800cc to 900cc of liquid nitrogen.

Related Posts: