`` SpotLESS Materials '' that allows toilets to play liquids and stickies and dramatically reduce the amount of washing water used

Because a large amount of water is used to clean the toilet, the toilet is not cleaned in an area where water is insufficient, resulting in sanitary problems. “If the toilet cleans itself, the problem will be solved.” When spray is sprayed on the toilet, water droplets, sticky substances, and bacteria will not repel and adhere. “ SpotLESS Materials Was newly developed by researchers.

Viscoelastic solid-repellent coatings for extreme water saving and global sanitation | Nature Sustainability

New, slippery toilet coating provides cleaner flushing, saves water | Penn State University

https://news.psu.edu/story/598131/2019/11/18/research/new-slippery-toilet-coating-provides-cleaner-flushing-saves-water

The power of spotLESS Materials can be confirmed from the following movie.

Water-Saving Toilet Coating-YouTube

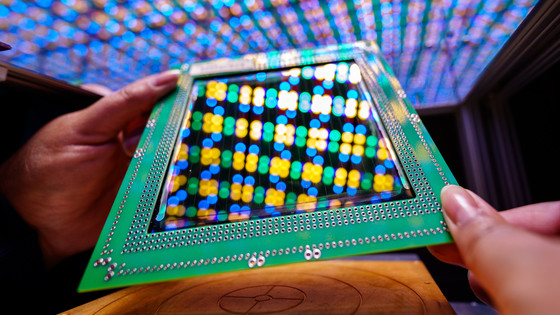

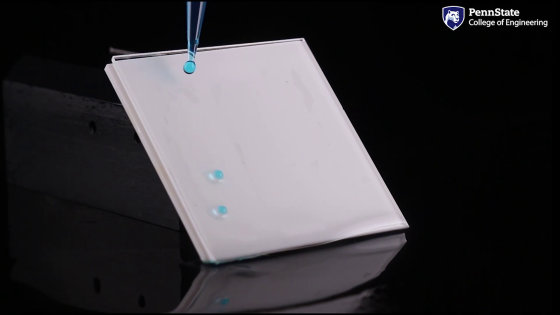

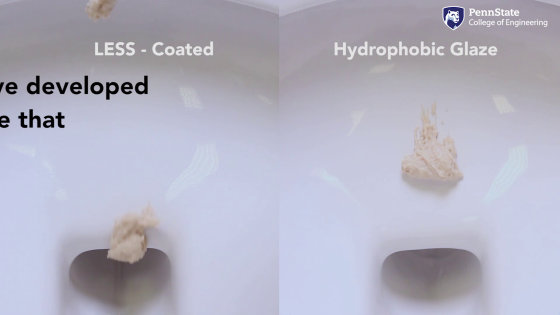

When the water drops are dripped, the water drops will slip on the surface of the glass.

This is the same for sticky solids as well as water drops. It is an object that seems to stick to the glass, but it will slide on without slipping on the glass.

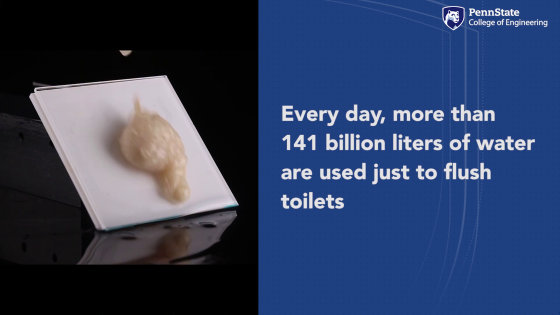

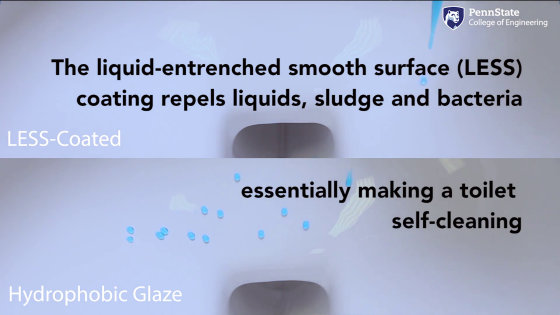

If the toilet bowl is coated with spotLESS Materials, even if there is no water, the waste will fall down without sticking to the toilet bowl. Every day in the world, 141 billion liters of water is used for toilet cleaning, but if you use spotLESS Materials, you can reduce the amount to about half.

No water will remain on the toilet bowl. Bacteria are also splashed, and the toilet bowl cleans itself.

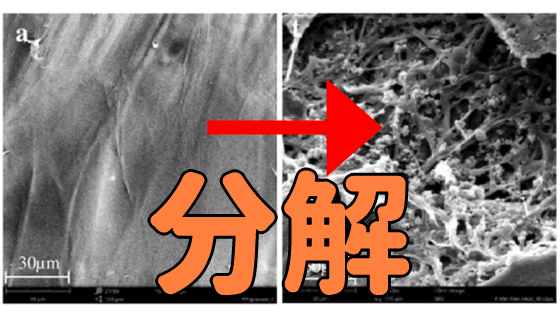

spotLESS Materials was developed by Professor Tak-Sing Wong, who studies mechanical engineering and biomedical engineering at Pennsylvania State University, and Jing Wang, a graduate of Professor Wong's laboratory. “LESS” of spotLESS means “liquid-entrenched smooth surface”, which is a two-stage spray. The first spray is made from a molecular graph and a polymer, which forms the basis of a very smooth surface and water repellency. The first spray creates a smooth surface and then sprays a second spray that acts as a lubricant.

According to researchers, the spray-coated toilet can withstand about 500 washings. If you lose your dominant eye, spray again.

There are other sprays like this, but in the case of other sprays, it takes time to actually use after spraying, whereas spotLESS Materials can be used in 5 minutes after spraying. The In addition, bacteria tend to spread in the toilet and cause odors, but as a result of experiments, it was shown that spotLESS Materials plays bacteria effectively.

In addition to reducing resources, this technology is thought to be used in “waterless toilets” in areas where water is scarce. `` A toilet attached to the stool not only discomforts the user, but also has serious health concerns, '' Wong said, spotLESS Materials is expected to help create a safer toilet .

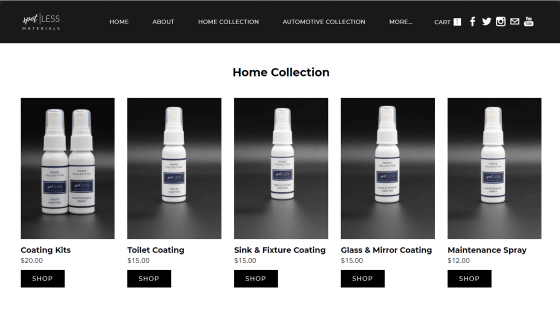

For this reason, Wong and Wang established startups. With the support of Ben Franklin Technology Partners and Y Combinator , it has already been commercialized. The price for the toilet coating kit is $ 20 (about 2200 yen), and shipping to Japan is $ 13.54 (about 1500 yen).

Shop-spotLESS Materials Website

https://www.spotlessmaterials.com/shop.html

Related Posts: