Succeeded in producing a toilet with almost no dirt with a 3D printer

When you use the toilet bowl of the toilet, dirt will inevitably stick somewhere, but a research team at

Abrasion‐Resistant and Enhanced Super‐Slippery Flush Toilets Fabricated by a Selective Laser Sintering 3D Printing Technology - Li - Advanced Engineering Materials - Wiley Online Library

https://doi.org/10.1002/adem.202300703

Nothing sticks: New silicon-infused 3D printed toilet bowl repels all

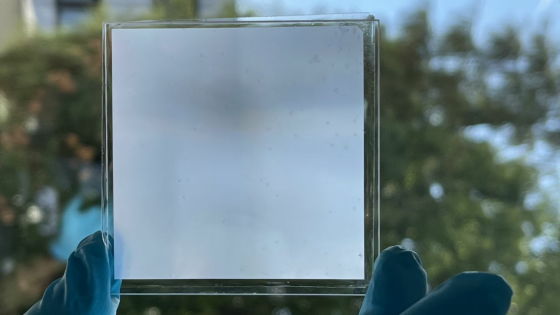

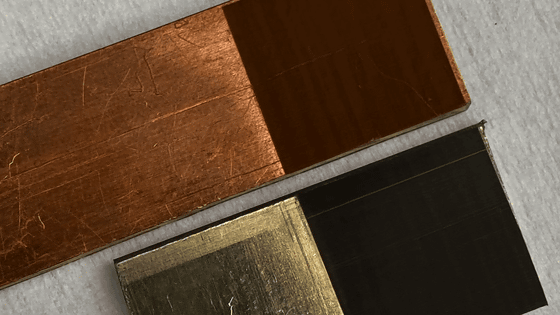

Yike Li and his colleagues at Huazhong University of Science and Technology have developed a new material that combines plastic and hydrophobic sand grains and infuses them with silicon-based oil. Mr. Li et al. named the toilet made of the new material 'abrasion-resistant super-slippery flush toilet: ARSFT (abrasion-resistant and very slippery flush toilet)'.

You can clearly see how difficult it is for dirt to adhere to the material and ARSS used in ARSFT by watching the movie published as a paper material. Below is a movie that combines the ones that were particularly easy to understand among the released movies.

What is the performance of 'ARSFT', a flush toilet that is resistant to abrasion and very slippery? -YouTube

It is continuously immersed in muddy water, milk, yogurt, honey, and Happo porridge , but the surface looks smooth all the time.

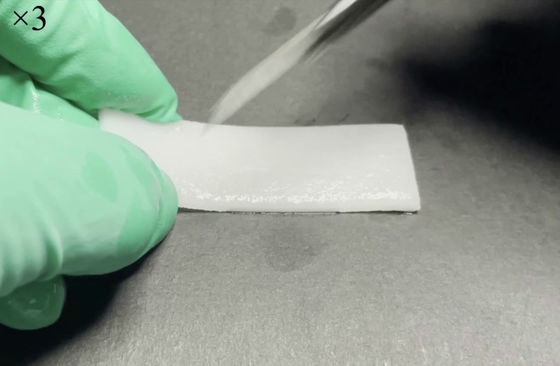

Next, the surface is scratched with a utility knife.

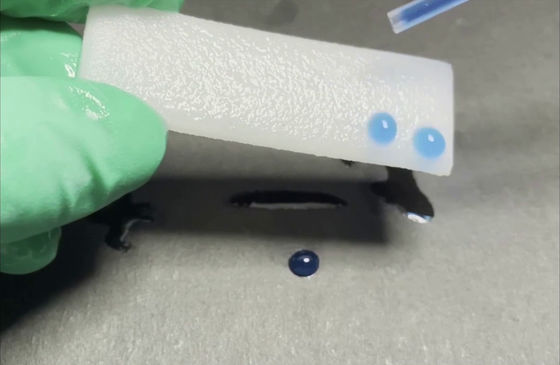

Even if you drop colored water droplets on the surface in this state, they will be repelled beautifully.

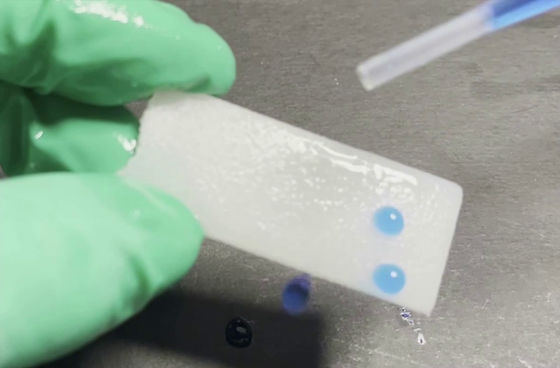

Now, scrape the surface with a file.

Still the water droplets were repelled.

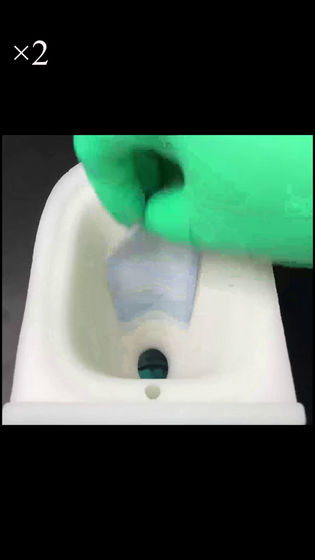

Synthetic feces have also been used to demonstrate how slippery the surface of the new material is. This is where synthetic feces was dropped into a toilet made using a highly hydrophobic material. Even at 2x speed, the synthetic feces stick to the toilet bowl.

On the other hand, with ARSFT, the synthetic feces slide down the moment they are dropped.

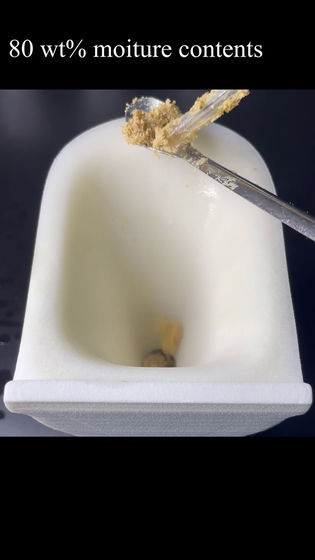

Experiments were also conducted with varying concentrations of synthetic feces. Synthetic feces with a concentration of 40

On the other hand, the 80wt% synthetic feces tumbled down without sticking to the toilet bowl.

As the name suggests, it is resistant to abrasion. First, 15 cycles of polishing were performed using sandpaper.

After that, even if I dropped synthetic feces, it slid without problems.

As expected, the surface was scratched by 1000 cycles of polishing, and the synthetic feces stuck to the surface and stopped.

However, when I applied the auxiliary lubricant, it slipped smoothly.

After that, the synthetic faeces began to slide down the surface, almost back to normal.

A test with a total of 8 liters of water was also conducted.

Even after that, the synthetic feces flowed without problems.

Yike Li et al. found that flushing toilets consumes 141 billion liters of water a day, six times the consumption of the entire African population. , ARSFT said it can also address the problem of 'wasted water'.

Related Posts: