How does a spray bottle ejecting liquid eject fluid inside?

by24oranges.nl

A spray bottle is a bottle that ejects liquid from the nozzle by drawing a lever without requiring power such as electricity or compressed air. Engineer's mechanism to disassemble and examine such spray bottleAlex EllisMr.My own blogIt explains in.

Why does a spray bottle work? · Caffeinspiration

https://alexanderellis.github.io/blog/posts/check-valve/

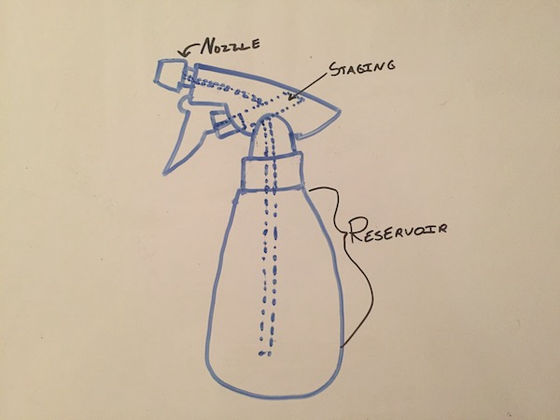

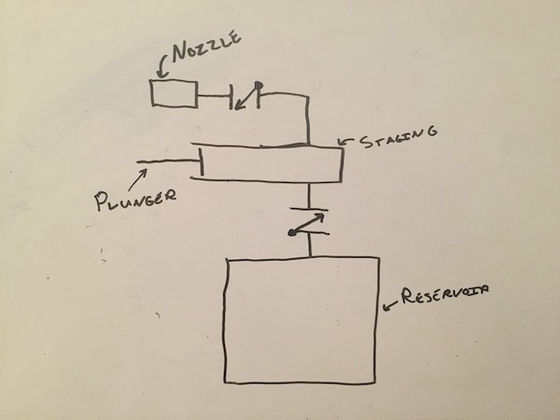

Spray bottle which puts fragrance, deodorant, alcohol for disinfection etc. in the bottle and pulls the trigger and scatters to the outside as much as you want is a very convenient and familiar device. Explaining the spray bottle in a simple diagram, it is as follows. The main components of the spray bottle are "RESERVOIR" for storing the liquid (fluid) to be jetted, "STAGING" for temporarily keeping the fluid to be jetted out, spraying the fluid to the outside of the spray bottle "Nozzle (NOZZLE)" can be divided.

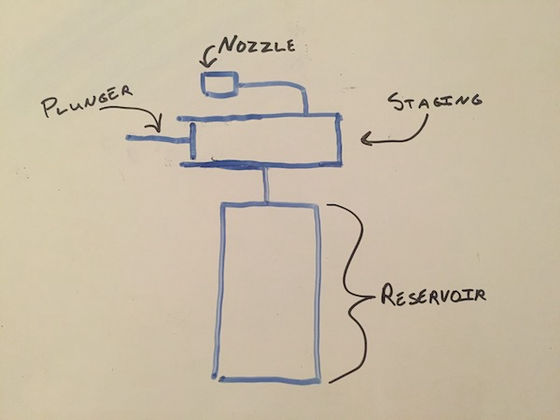

Here, fluid refers to one in which particles are not fixed but flow. Liquid such as air such as tap water and alcohol for disinfection is fluid as well, and the spray bottle can be said to be a device which plays a role of distributing internal fluids to external fluids. Further simplifying the spray bottle is as follows. For staging, pumping fluid like a piston "Plunger(PLUNGER) "is installed, and the fluid inside the staging is controlled by the plunger's action.

In the spray bottle,User interfaceIt is a trigger. Trigger most often a simple lever which is connected to the plunger, the fluid pooled in the staging Pressing the trigger is pushed out, it is ejected from the nozzle. When the fluid is ejected and the trigger is loosened, the internal spring is pushed back,vacuumFluid is drawn into the staging from the reservoir by the effect of. By repeating this cycle, the spray bottle can draw a trigger continuously and blow out the internal fluid.

"To operate a spray bottle effectively, two important factors are necessary," Ellis says. First of all, the first element is "the fluid in the staging spouts out through the nozzle and out". Spray bottles will not do anything if fluid returns to the reservoir. And secondly, "The fluid replenished when the trigger is released is not fluid outside the spray bottle (air), but fluid in the reservoir." If the air flows in from the outside into the staging, the spray bottle will be a device that just blows out the air.

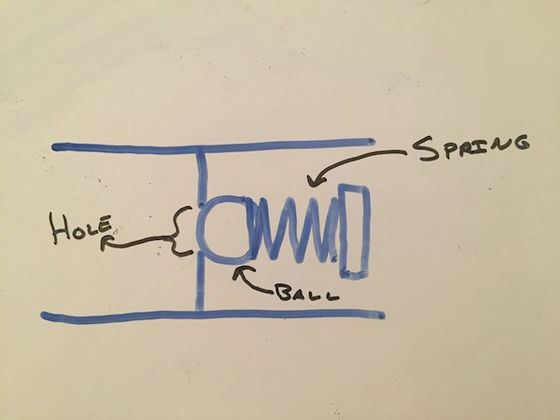

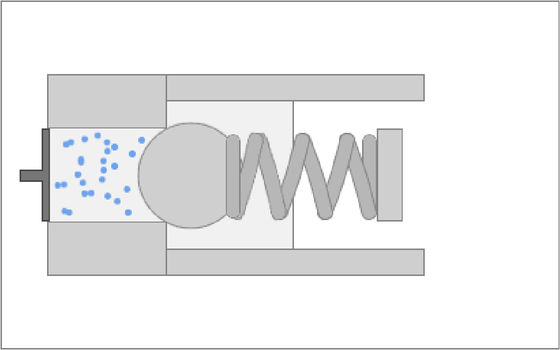

These two problems are such that the fluid moves only in one direction of "reservoir" → "staging" → "nozzle" in the spray bottlevalveYou can solve it by creating. By creating a simple valve in which the fluid moves only in one direction and connecting the valve to the two locations between the staging and the nozzle during reservoir and staging prevents the staging fluid from returning to the reservoir, It is also possible to prevent staging. Ellis disassembled the spray bottle and found out that the valve consisting of the ball / spring · cylinder with one hole was used as follows as a result of investigation.

The pressure of the spring and the pressure of the right fluid press the ball against the hole of the cylinder to prevent the fluid on the spring side from flowing into the cylinder. At the same time, the ball pressed into the hole prevents the fluid in the cylinder from flowing out to the right side, and the state where there is no fluid movement is kept.

Now, pull the trigger, move the plunger, and try increasing the pressure inside the cylinder. Then, the fluid in the cylinder can not withstand pressure, it begins to move, and pressure is applied to the ball pressed against the hole. When the pressure inside the cylinder exceeds the pressure exerted by the spring and the right fluid (air), the ball is pushed out and fluid in the cylinder escapes from the clearance between the ball and the hole. When stopping applying pressure from the plunger, the pressure received from the spring and the right fluid again exceeds the pressure inside the cylinder, and the ball is pressed against the hole to close the gap.

By connecting the valve with the above mechanism between the reservoir and the staging and between the staging and the nozzle, the direction of fluid movement in the spray bottle is limited to one direction. The model diagram showing the direction of movement of the fluid in the reservoir and staging, the valve installed between the staging and the nozzle is as follows.

When the pressure inside the staging is increased by pulling the trigger and moving the plunger, the valve between the staging and the nozzle opens, and the fluid in the staging blows out through the nozzle. Loosening the trigger closes the valve and the outside air never comes in staging. At the same time the inside of the staging is in a vacuum state, the valve between the reservoir and the staging opens, and the fluid in the reservoir is replenished into the staging by the effect of the vacuum. Ellis explains that this is how the spray bottle works.

Related Posts: