Researchers and others develop water repellent finish on synthetic leather with nanotechnology to make the fabric sticky even on hot days

byTakashi. M

Ohio state university researchers announced that "developed technology that uses nano-technology to make synthetic leather resistant and oil resistant," which was inspired by the leaves of leaves. Because synthetic leather uses plastic, it is vulnerable to heat, but it has permeability, but if you use this technology you can make various things such as clothes, furniture, car seat, waterproof, oil resistant and heat resistant.

A better fake leather, inspired by plants | The Ohio State University

https://news.osu.edu/news/2018/04/23/a-better-fake-leather-inspired-by-plants

Lotus inhabits muddy ponds and swamps, but leaves and flowers are kept clean, so Hinduism has been regarded as a symbol of purity and goodness. This is because the gins have natural self-cleaning function. Lett's leaves have the property that water attached to the surface rounds like water droplets, rolling down while mud, foreign matter, small insects etc. are caught in due to the characteristics of the fine structure of the surface. this is"Lotus effect"It has been used in the field of nanotechnology. As what can be seen on a daily basis,Lid of cup of yoghurt etcThere are examples in which yoghurt is difficult to attach to the back of the lid by using Lotus effect.

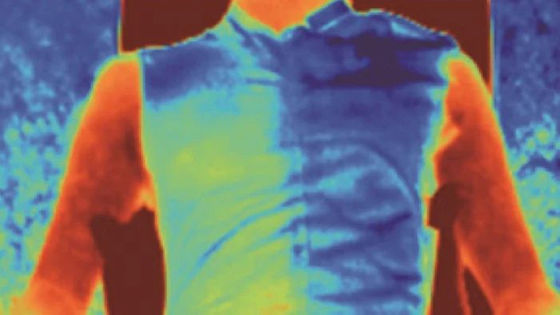

According to the content published at journal Colloids and Surfaces, researchers have processed the plastic-based leather shell using the lotus effect and succeeded in allowing both oil and water to roll off the surface about. There will be no sticking to other materials until the surface temperature reaches 70 degrees, so that trousers will not stick to the seat when you get on the car and you will not feel uncomfortable.

Bharat Bhushan, a mechanical engineer at Ohio State University who conducted the research said, "Today, the leather is easy to handle and cheap, so the popularity in the market is rising.We know, not only water but also oil This research is the first time that we have produced a synthetic leather with repelling liquid affinity, "he said.

Many synthetic leathers are fabrics coated with materials such as polyurethane and polyvinyl chloride. Both genuine leather and synthetic leather have some common point that they are somewhat permeable, but unlike real leather, the plastic used in synthetic leather has soft surface because of heat, so the surface becomes sticky as the temperature rises It has properties.

The researchers sprayed silica nanoparticles on the surface of the synthetic leather and tried to reproduce the same decoy bob as that of the leaves. However, as a result of experiments, we found thatPlasticizerIt turned out not to adhere the nanoparticles. Therefore, when researchers applied ultraviolet rays as done in computer chip manufacturing, they seemed to succeed in bonding the nanoparticles to the synthetic leather. Nanoparticles sealed with silicone resin as a finish can hardly be seen from the outside, and it seems that appearance is nothing different from ordinary synthetic leather.

The way to test how the synthetic leather you developed will repel water or oil can be seen from the following movie.

Self Cleaning Synthetic Leather - YouTube

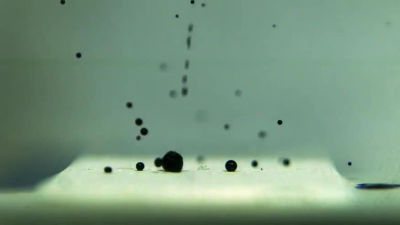

The upper part of the image below is raw leather and the lower part is processed leather. Even if raw skins are twisted twice, water droplets continue to stay on the fabric, whereas in the case of processed leather it is found that water droplets are rolling around.

For oil it is like this. Also this is the upper row processed and the lower row processed. In the case of oil it was shown that it rolled down at an inclination of 4 degrees.

Also, sapphire beads made scratching 100 times back and forth of the synthetic leather after processing, it seemed to require a 7 degree inclination, but the droplet still fell down. This showed that even if the synthetic leather wears, the water repellency is not lost. When a drop sliding down the synthetic leather entered the groove, it took a slope of 44 degrees to slide off, but in the case of raw synthetic leather it is a place requiring 90 degrees The difference is large.

Furthermore, when black silicon carbide powder was sprinkled on the processed synthetic leather and it was investigated how much it washable with one piece of water drop, the raw synthetic leather removed 10% of the powder, and it was processed The skin coat has succeeded in removing 90%.

Related Posts: