How do Apple's top secret "Input Lab" first infiltration repo and new accessories are tested and manufactured?

Apple announced the new donut headquarters "Cupertino, California"Apple Campus 2In addition to the head office, Apple's offices are dotted around the world. At a distance of about 280 miles (about 450 km) from the new headquarters, a private secret research laboratory "Input LabThere was a report article that succeeded in internal coverage for the first timeMedium, And the process of designing, testing, and manufacturing Apple accessories is revealed.

What I Saw Inside Apple's Top-Secret Input Lab? Backchannel? Medium

https://medium.com/backchannel/what-i-saw-inside-apple-s-top-secret-input-lab-6637e2e5492e

The inside of "Input Lab" has never been published before, but AppleNew iMacIn conjunction with the launch of the first time in the laboratory to increase the transparency of the product. Inside of the room is clean impression based on white, new design making such as keyboard, trackpad, mouse etc and prototype operation test are carried out.

In the "user test division" in the laboratory, tests are being conducted by subjects to sit in front of the keyboard with the sensor attached to the body, and to measure the effect on the body when using the keyboard. According to Kate Bergeron, Vice President of Ecosystem Product Technology Division, subjects will be collected from various departments within Apple. Bergeron says, "Each time the user tests are repeated, the speed at which subjects can strike the keys accurately is gradually increasing," he says.

Subjects attach a sensor to the back of the hand or arm and operate the keyboard as follows.

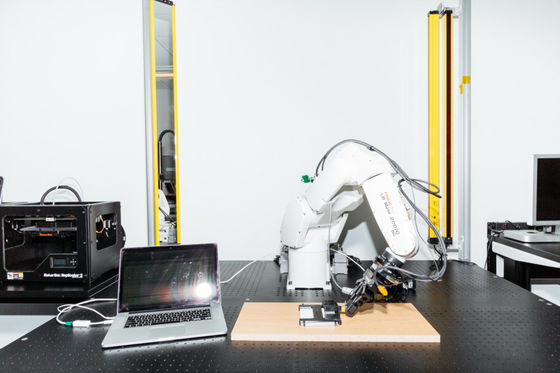

The next room is "Characterization Department." All Apple products are going to go through product tests done in this room before launch. A robot typing the keyboard to measure the performance and durability of the product, and a robot that repeats clicking and moving operation of the mouse are filling the room.

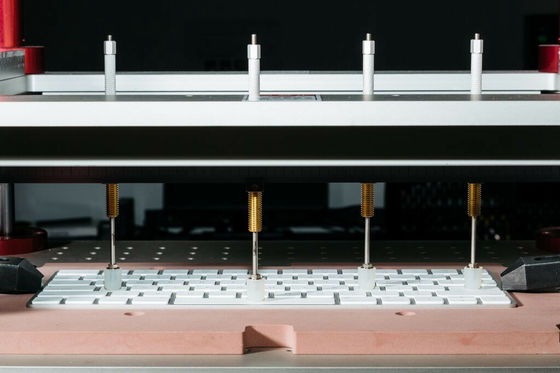

The following white machine is a test robot for repeating keystrokes on the keyboard.

The tapping robot has a "tapper" for hitting a key, and it is possible to key a key continuously. In the operation test of the keyboard, it is said that a test will be carried out in which the key is touched five or more times in total at the four corners and the central five places. Also, the prototype model of the keyboard seems that one key is made twice as large as the product version in order to check whether the sensor embedded under the key works well .

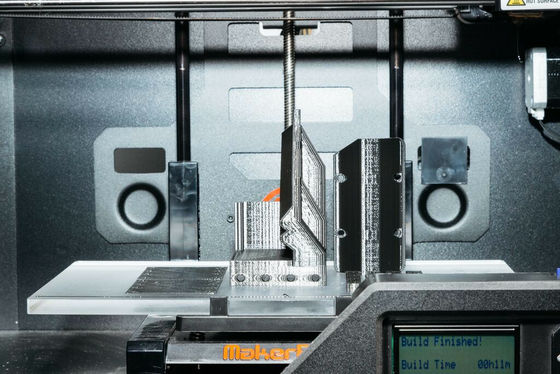

It seems that parts for robot necessary for testing are output using MakerBot's 3D printer.

In the operation test of the mouse, the mouse is placed on various materials such as wood, glass, metal, melamine, concrete, etc., and the operation test is carried out.

This is a special machine for keeping clicking only the right mouse button.

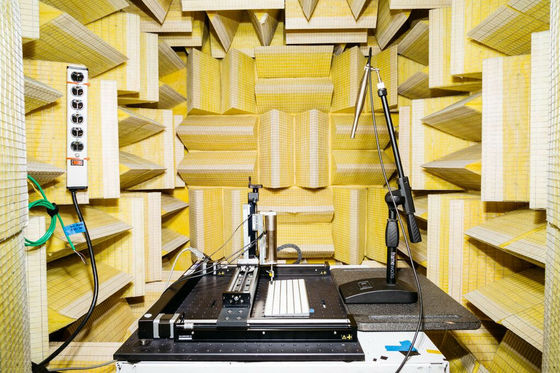

In "Acoustic chamber", it is being tested whether mouse click sound or keyboard tap sound matches the product. It is said that the checking of the striking sound is carried out by the machine and the hands of a human being so that the situation is not caused that the keying sound changes as the parts are shifted while the product is being transported.

The interior of the acoustic room is as follows and it is surrounded by materials with high sound insulation.

Related Posts:

in Hardware, Posted by darkhorse_log