"The Art of Shoe Making" in which the whole process of handmade the best leather shoes is known in only 3 and half minutes

Established in 1840, it is said to be called "the world's best leather shoes store" of a long-established British storeBespokeLeather shoes store "Foster & Son"is. The style which finishes handmade authentic English British leather shoes one by one according to the order of customers as much as there are fans all over the world. A Japanese coworker, Mr. Riko Matsuda who works at Foster & Son's London shop, artistic craftsmanship from wooden making to finishing leather shoes, made it a picture of only three and a half minutes "The Art of Shoe Making"Is published on YouTube.

The Art of Shoe Making - YouTube

There is no narration or subtitles in this movie, and the process where light leather shoes are made with music will be reflected. First, leather shoemaking is "lastIt begins with making a wooden pattern called "Sakura".

Because the comfort is greatly different depending on the size of the last, I will scrape the wooden pattern gently so that it fits perfectly with the measurements of the measurements of the feet of the ordered orderer.

Once finely adjusted with file, the last making process is over.

I will make a pattern for cutting out leather according to the last shaved out with paper.

Leather is cut according to the paper type. There is no need to use a cutting machine, etc. The skill of craftsmen and the appearance that leather is splendidly cut with one knife is unexpected spectacle.

We do not mass-produce, one by one craftsmen are sewing leather with a sewing machine.

Looking somewhat sewing the "upper leather" which is the part of the instep part of the foot of the leather shoes look like this.

Also, because leather shoes have multiple parts, processing such as shaving the back side thinly will be done so that the part where the leather overlaps does not become decorative.

In familiar with leather shoesHole decoration"It seems that it is vacated by hand one way.

When sewing the decorated leather with a sewing machine, the shape which seems to be leather shoes finally became visible.

At this time, you can see that a special base attachment is used so that three-dimensional leather shoes can be sewn with a sewing machine.

Next I will sprinkle white powder on the last. This is to make it easier to remove the last.

Let us wear the leather stitched last so far. this is"FishingProcess called so.

The edge of the leather stops the last place. It seems that skill of craftsmen also appears in the tension of this leather.

The portion where wrinkles are included is "hit" with a hammer, and adjusted so that a beautiful curve appears.

Next, the "insole" of the bottom material entering between the insole and the sole is attached by hand sewing.

While sewing the insole, remove the temporary stop.

Of course the shoe sole is finished by hand sewing ......

I can see that the bottom of that leather shoes are tied firmly with one needle and one hand.

The heel is installed at this stage ......

Fixed firmly with a hook.

At first this side is irritated like this, but it is cut off with a knife carefully.

Tap on the side of the heel further with iron ... ...

It finished smoothly with filing.

Also rubbing side with a throat with ironing. This puts a brazil on the heated iron "Ironing"In the process of tightening and tightening the fibers of leather, you can give luster and waterproofness by applying wax uniformly.

This completes all processes. Finally if you tailor it with shoe polish ... ...

This is a beautiful made-to-order UK shoe made by the world's best craftsmen.

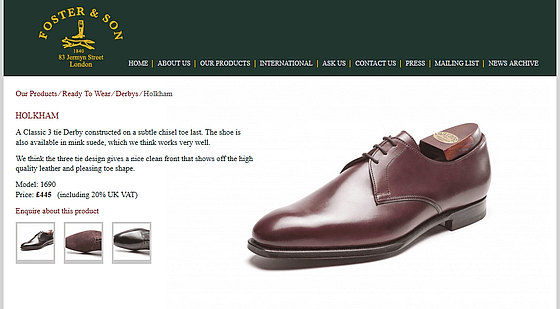

In addition, because Foster & Son's leather shoes are made to order, price will go up and down, but if it is the following shoes it is 445 pounds including tax (about 80,800 yen).

Related Posts: