Using modern technology to create a top that keeps spinning for a long time

Tops are a beloved toy for generations, but they have a limitation: they eventually slow down and stop spinning. Engineer and YouTuber Aaed Musa has released a video showing how he combines modern electronic components and prototyping techniques to build a motorized top that will keep spinning for as long as possible.

During development, Musa set a constraint that all mechanisms, including the power source, circuitry, and battery needed to maintain rotation, be contained within the top. Rather than relying on external electromagnets on the base or a direct motor on the ground, Musa aimed to generate rotation entirely within the top.

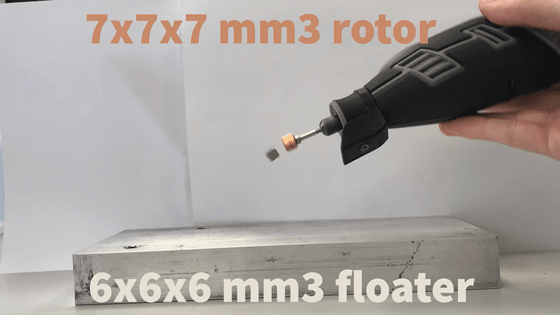

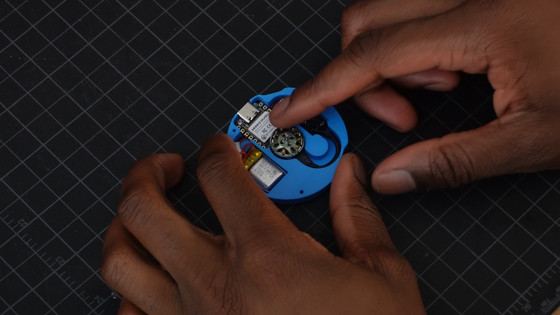

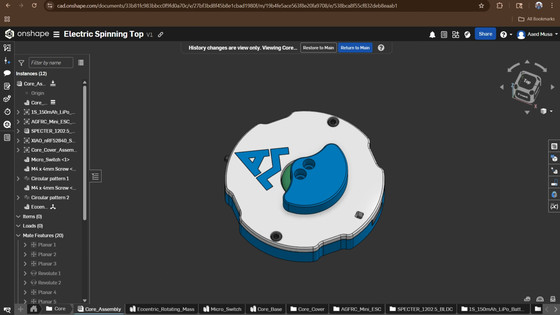

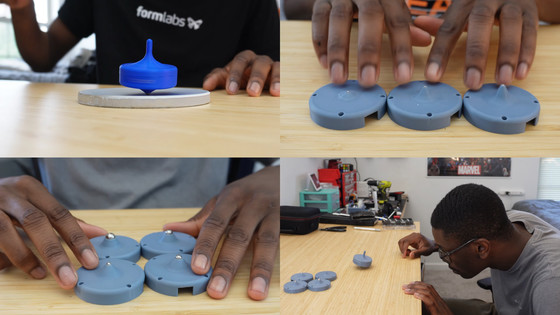

Musa's initial idea was to miniaturize a reaction wheel, known for its use in satellite attitude control, and use the law of conservation of angular momentum to apply a reactive torque to the spinning top itself. He continued his research on the premise of incorporating a brushless motor designed for small drones, an ESC (electronic speed control circuit), a small microcomputer, and a 3.7-volt battery, with the status readable by an IMU (inertial measurement unit).

However, with the reaction wheel method, the motor can only accelerate up to the maximum rotation speed, and eventually acceleration will stop. The state in which the reaction wheel can no longer accelerate is called saturation, and once saturated, it can no longer continue to provide new rotation to the top itself. To eliminate saturation, deceleration is necessary, but this deceleration cancels out the effect of the rotation that had been created up to that point, so we concluded that this method is not suitable for maintaining rotation for long periods of time.

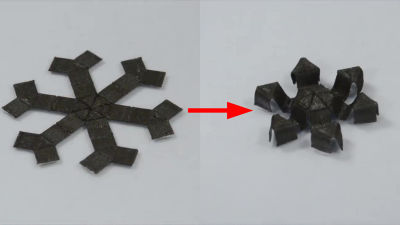

Instead of using a balanced wheel, Musa decided to use an eccentric rotating mass (ERM), which is an off-center mass. This intentional imbalance creates vibrations, similar to the vibrations that occur in smartphones, and ultimately creates a circular motion at the tip of the top, helping it maintain its position.

After the ERM method was able to stand on its own, it became necessary to make adjustments to suppress unnecessary vibrations in the core as a whole while maintaining the desired eccentricity. Musa created screw holes in the cover and used the screws themselves as counterweights to achieve the right balance, which resulted in a significant improvement in behavior even with fewer screws.

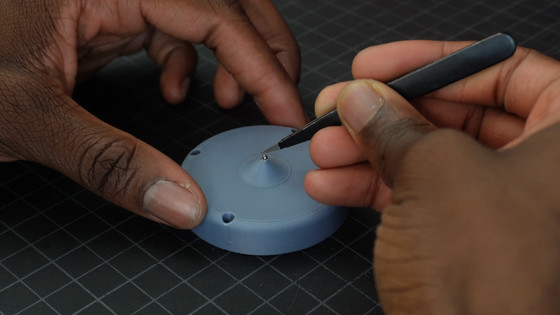

Additionally, since the tip of the 3D printed top is prone to wear, we replaced the tip with a steel ball bearing to improve durability. Finally, we also introduce the option of using ceramic ball bearings for a harder, smoother tip.

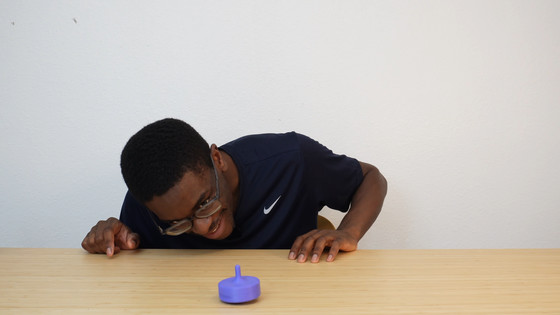

To find the optimal shape, Musa designed, built, and evaluated a total of 42 prototypes over several weeks. Some prototypes spun well and could continue to spin for over an hour, while others fell over easily. By comparing the prototypes, he was able to identify factors that affected stability.

The first key point outlined is the moment of inertia. In a typical top, the larger the radius and mass, the greater the moment of inertia, making it easier to generate initial rotational energy. In an electric top, the moment of inertia of the eccentric weight is more effective than the moment of inertia of the main body, so it is important to make the eccentric weight appropriately heavy and large.

The second is the height of the center of gravity. If the center of gravity is as low as possible, the torque exerted by gravity in the direction of tipping when tilted will be smaller, making it easier to maintain posture.

The third factor is the size and material of the tip. Generally speaking, the smaller the tip, the less friction there is and the more advantageous it is. However, in Musa's case, a medium tip size was easier to handle in terms of stability. A ball bearing, which is resistant to wear, is effective, and the harder and smoother the material, the more advantageous it is in terms of performance.

For control to maintain rotation, we considered PID control to match the target rotation speed, and tried methods such as approximating the angular velocity from the angular acceleration of the IMU to measure the rotation speed, and inserting a magnet into the eccentric weight and reading the rotation period with a Hall effect sensor.However, in reality, these measurements and controls were not very effective compared to the effort required, and simply rotating the motor at a constant speed was enough to achieve stable operation, so we ultimately settled on a simple constant speed drive.

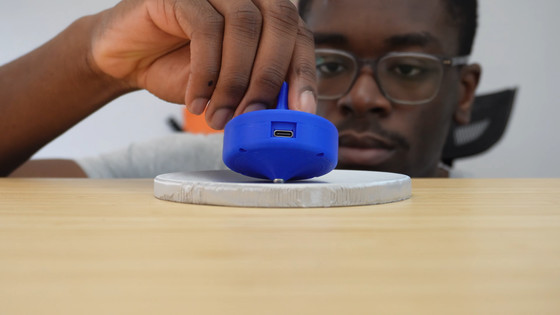

For the housing, we finally decided on a CNC-machined aluminum shell, achieving both a high-quality appearance and practicality.

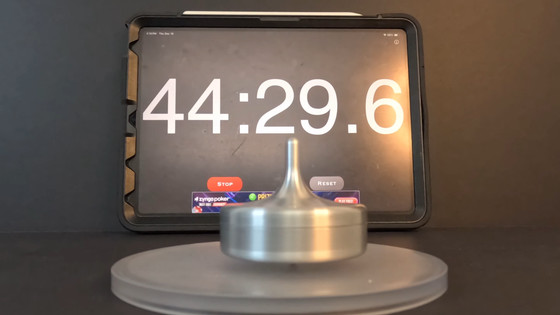

The completed motorized top is said to have achieved more than two hours of continuous spinning on a single charge. Musa reflects that by incorporating modern ideas of construction and control into a traditional toy, he has made the experience of spinning for a long time a reality.

Related Posts: