How was 'ultra-thin motor printed on printed circuit board' made?

Carl Bugeja , a software developer and an electronics engineer, said, "I made an ultra-thin motor using printed circuit boards " and explained how to make motors using printed circuit boards I will.

PCB Motor | Hackaday.io

https://hackaday.io/project/39494-pcb-motor

How to Print an Electric Motor - IEEE Spectrum

https://spectrum.ieee.org/geek-life/hands-on/how-to-print-an-electric-motor

Mr. Bugeja said that he wanted to create an ultra-compact drone, and started developing the ultra-small motor as a result. However, Mr. Bugeja eventually says that he noticed that "there is a limit to the size reduction of the drones and that the motor is responsible for making the limit."

As you drag a drone using a motor, you need a motor that has the ability to fly a mass object that added the weight of the motor itself to the drones parts. Bugeja thought that the weight of the motor body would be a bottleneck to miniaturize the motor to be mounted on the drone, and in some way Mr. Bugeja began to think whether the motor could be constructed with few parts and reduce the mass.

Mr. Bugeja, who was working on making ultra-small motors, got the idea from a type of planar antenna called a microstrip antenna made by using copper wires drawn on a printed circuit board, "To rotate the motor from the conductor of the printed circuit board I thought that I could create the necessary magnetic field? " Mr. Bugeja made a brushless motor using a disk-like rotor ( rotor ) at the rotating part of the motor and a printed circuit board on a stator ( stator ) that rotates the rotor.

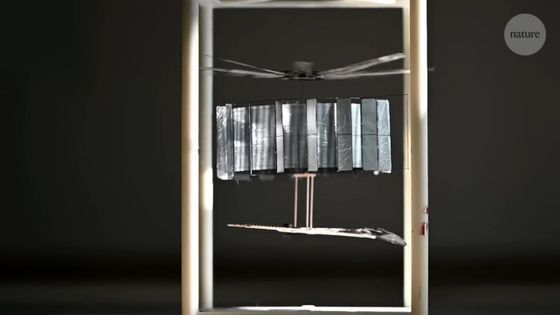

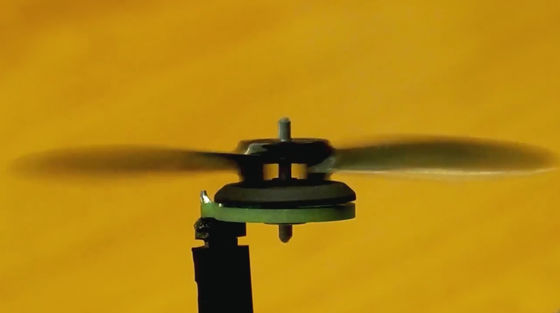

The state of the motor actually made by Mr. Bugeja can be checked from the following movie.

Motor made from a PCB!

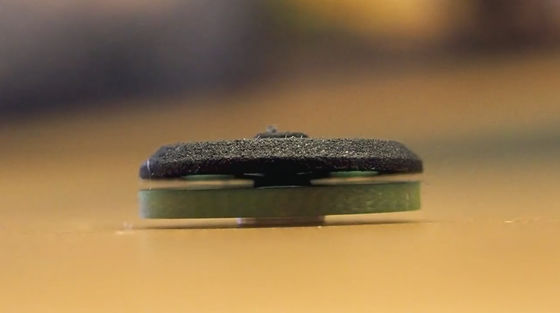

Kukuru and a rotating disk. At first glance it looks like a coma, but ...

It is a fresh brushless motor made by Bugeja.

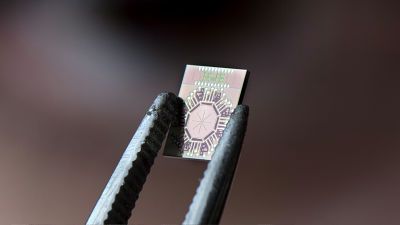

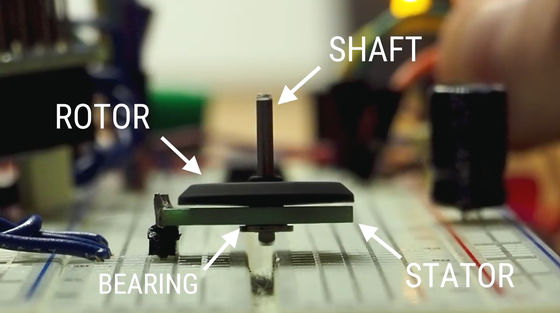

The middle rod is a shaft, the black disk is a rotor, the green base is a stator made of printed circuit board, there is a bearing at the bottom.

In a normal motor, a coil wound with a wire is used for a stator that generates a magnetic force and rotates the rotor ... ...

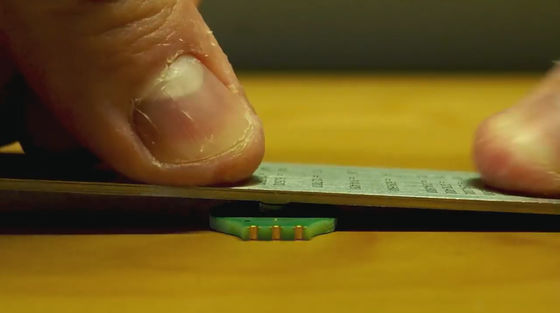

Bugeja uses a printed circuit board as a stator instead of a coil.

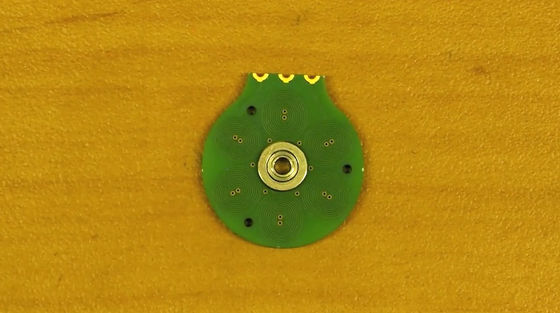

On the printed circuit board, six coils of coils are printed as conductors, which are stacked in four layers. Although it seems that the magnetic force sufficient to rotate the rotor was not obtained with one layer of printed circuit board, it was possible to secure sufficient magnetic force as the motor stator by stacking four layers of thin printed boards.

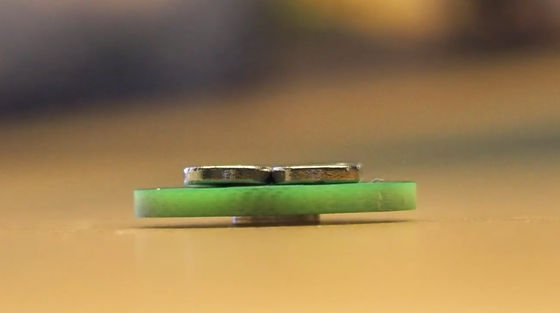

In the rotor put on the stator, a permanent magnet is embedded ......

It is installed in parallel with the stator. The rotor was made with a 3D printer, the snap fit to be connected with the shaft was integrated with the rotor itself, we were able to reduce the parts making up the motor to only rotor, permanent magnet, bearing, printed circuit board .

When a current is passed through the stator, a magnetic field is generated and the rotor rotates properly. The diameter of the rotor is 16 mm, it is about the same as the smallest brushless motor on the market.

Since brushless motors do not use a commutator that periodically alternates the direction of the current to keep rotating the rotor, we normally use an electronic control system that detects the counter electromotive force and controls the rotation of the rotor . Such an electronic control system receives the rotation of the rotor as feedback by detecting the counter electromotive force generated in the coil of the stator and synchronizes the rotation and the current direction.

However, the back electromotive force of the brushless motor using the printed circuit board created by Mr. Bugeja was too weak, and it was impossible to synchronize the rotation of the rotor and the current direction using the counter electromotive force. Mr. Bugeja therefore measured the change in the magnetic field generated by the motor directly and installed a sensor that measures the speed at which the rotor and the permanent magnet embedded inside the rotor are spinning. With this sensor, the electronic control system has detected the rotation of the rotor and successfully synchronized the current properly.

Mr. Bugeja's motor said that the torque of the rotor is not enough and there is no power enough to skip the drone. However, it is much thinner and cheaper than the conventional brushless motor ......

It is said that manufacturing is easier.

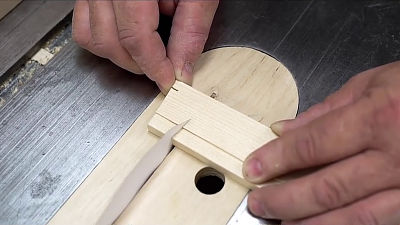

In fact, Mr. Bugeja assembled an ultra-thin motor without difficulty by hand without using special equipment.

Pass the stator made of printed circuit board on the shaft ......

Embed the permanent magnet in the rotor.

If the rotor also passes through the shaft ......

The brushless motor is completed in no time.

Related Posts: