A beginner's guide to mechanical key switches: 'Just this is all you need to know'

Recently, there are more and more mechanical keyboards that allow you to replace the mechanical key switches yourself, but there are many different types such as red and blue switches, which can be a bit confusing. Key switch collector ThereminGoat explains the structure of such mechanical key switches and the benefits of using them.

A Beginner's Guide to Switches — ThereminGoat's Switches

If you've ever removed the keys from a laptop, you've probably seen rubber-like parts in the switch area. The mechanical key switches used in mechanical keyboards are not made of rubber, but are made of metal and springs.

ThereminGoat said, 'When you see how you have to press a longer distance than with a rubber switch, you might think, 'Isn't this pointlessly complicated?' But regardless of how you use your keyboard, there are big advantages to using mechanical key switches compared to rubber.'' He introduced some advantages.

The biggest advantage of mechanical key switches is said to be the reduction of repetitive strain injuries. In other words, it means less fatigue caused by touching the keyboard for long periods of time, and the key point is that mechanical key switches increase cushioning through their operating distance and internal design. Other benefits include the obvious advantage of being highly customizable and having a long lifespan.

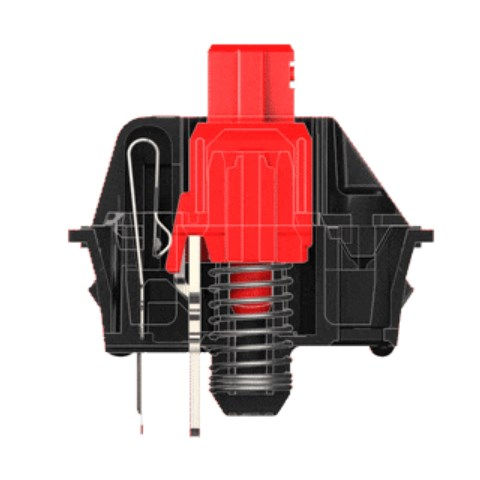

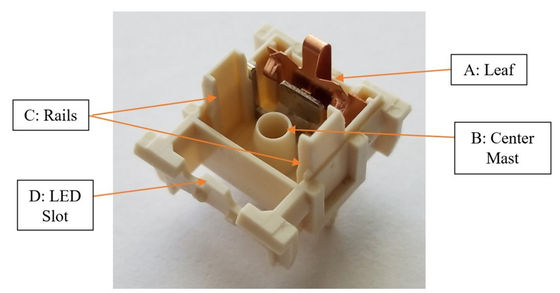

Next, ThereminGoat explained the mechanical key switch by dividing it into five parts.

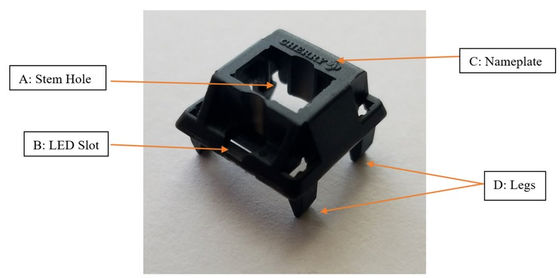

◆Top housing

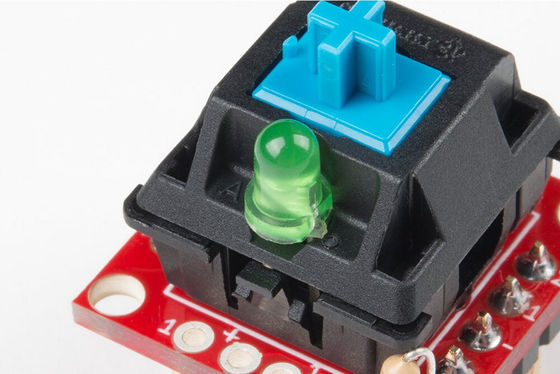

This is the top part when you remove the switch cover. It is particularly notable for the LED slot (B), which on some keyboards allows you to insert an LED pin into this part to connect it to the circuit board and light up the key.

Once the LED pins are inserted, it looks like this. A notable feature is that some boards are oriented 'north-facing' or 'south-facing', and those with the LED pins on the bottom when viewed from the front are called 'south-facing'.

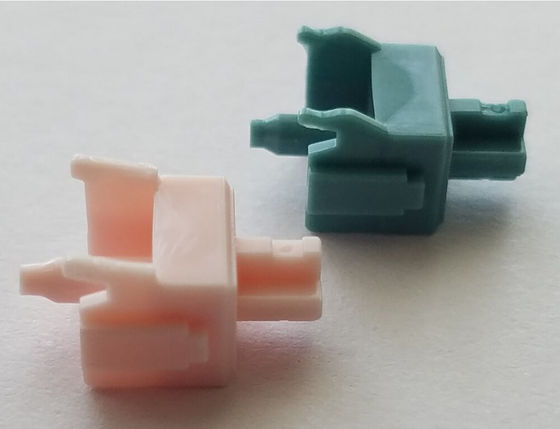

There are also variations in the legs of the top housing; the most common are those with hooks in two places, top and bottom or left and right (wing latch) and those with hooks on all four corners (4-pin).

By attaching a part called a 'stem' to the top housing, it will look more realistic.

◆ Stem

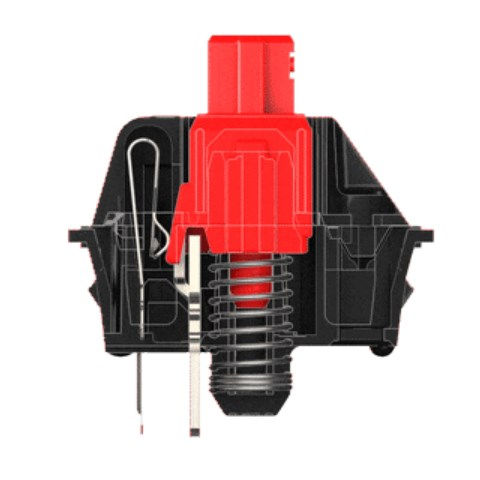

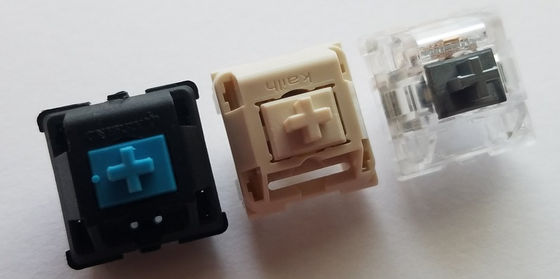

The stem is said to be the part that receives the most consideration during the design stage. The shape of the so-called linear (red axis), tactile (brown axis), or clicky (blue axis) is decided here.

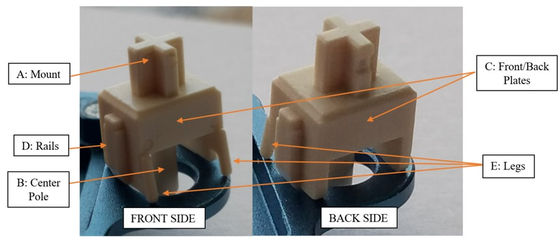

The topmost part is the 'keycap mount' or 'mount' which protrudes from the center and is what actually attaches the keycap to the switch.

The most common design is the 'cross mount' with a cross-shaped protrusion. The outlet hole-like design is only seen on low-profile switches, so it is called the 'low-profile mount.' The 'Alps mount' designed by Alps Alpine (formerly Alps Electric) is characterized by its long horizontal rectangle.

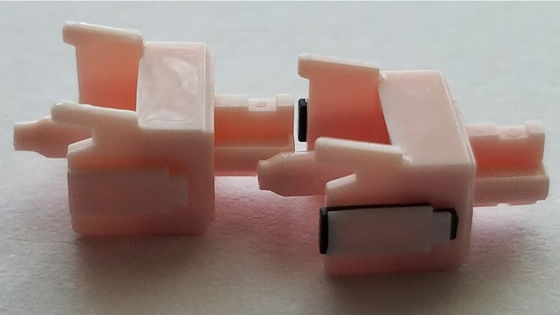

An important part of modding a switch is the rails on either side of the stem. There are two variations, as shown in the image below, the left stem has a normal rail, and the right stem has rubber protruding above and below the rail. These rubber pads are often found on so-called 'silent' switches, and are used to dampen the sound when the stem makes contact with the top housing or other parts.

Finally, there are the 'feet.' The legs of a switch are two small protrusions that extend diagonally from the stem and interact with another switch part called the 'leaf' to not only actuate the switch, but also create its clicking characteristic.

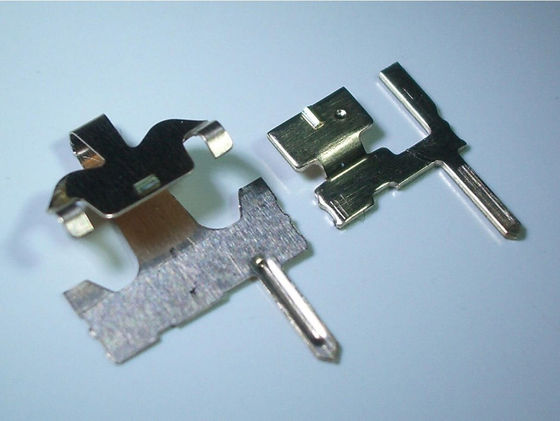

◆ Leaf

The most complex part of a mechanical key switch is the leaf, which is made of metal.

Normally, two leaves are installed vertically, and input is detected when the leaves come into contact with each other due to the up and down movement of the stem. Because the leaves are fragile, they are usually not removed from the bottom housing.

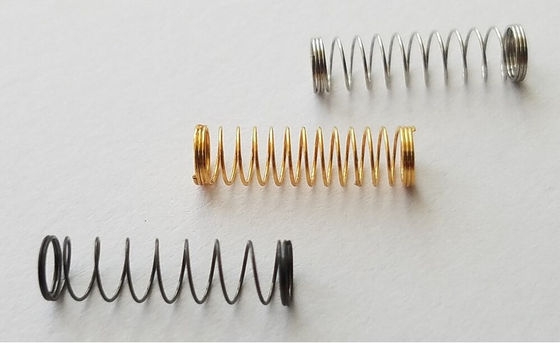

◆Spring

After the stem, the spring is the second most important element in the click characteristics of a switch. There are several variations in the appearance of the spring, characterized by small differences such as the number of turns per length and the material. In most cases, the spring is made of steel.

There are three main types: linear, progressive, and complex. Linear springs provide a constant force while the switch is activated, progressive springs gradually increase in force as the switch is pressed, and complex springs are a hybrid of the two, starting out linear and then transitioning to progressive.

◆Bottom housing

At the bottom of the switch is the bottom housing, which holds the internal components of the switch and allows the switch to fit onto the circuit board underneath the keyboard.

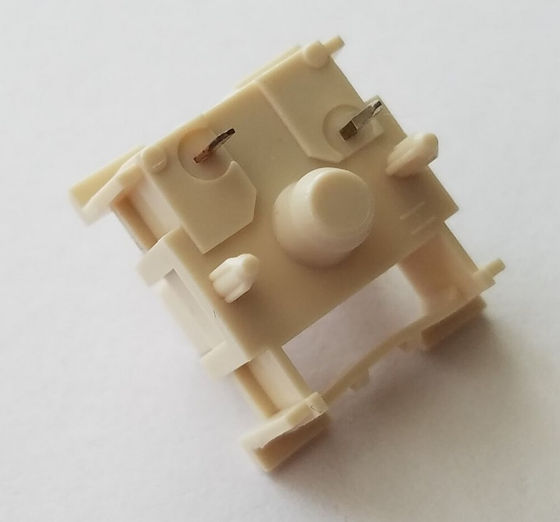

Looking at the back of the bottom housing, we can see a metal protrusion that serves to receive the 'leaf' legs and connect them to the board.

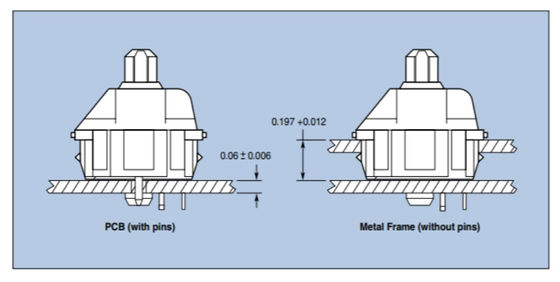

There are also several types of bottom housings, some with no protrusions on either side (left image) and some with (right image). These protrusions are called 'PCB mount legs' and are used to effectively secure the switch to the circuit board. If they have PCB mount legs, they are sold as 'PCB mounts' and if they don't, they are sold as 'plate mounts'.

In fact, some circuit boards have holes for attaching PCB mount legs, and some do not. If you want to install a switch with PCB mount legs on one that does not have holes, you will have to scrape them down at your own risk.

ThereminGoat said, 'Mechanical keyboards have a lot of complexities, but in most cases you don't need to know every detail of the parts and components you use. However, switches are essential to building a mechanical keyboard. It's useful to know more about switches.'

Related Posts:

in Hardware, Posted by log1p_kr