Pointed out that the global shortage of semiconductors will continue

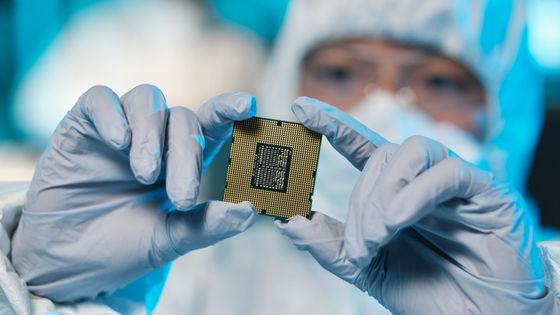

The shortage of semiconductors used in various electronic devices has led to delays in the development and sales of various products such as smartphones and PCs, resulting in an unprecedented increase in demand in each country. Mr. Graham Scott, Vice President of Global Procurement at

Why The Chips Are Down: Explaining the Global Chip Shortage | Jabil

https://www.jabil.com/blog/global-chip-shortages.html

Even in 2023, the global shortage of semiconductors will not end, and the demand for semiconductors is higher than ever. Globally, the semiconductor industry is expected to grow about 7% in revenue from 2021 to 2022, and the development of the Internet of Things (IoT), 5G, and automobiles is particularly remarkable. Jabil's market data and customer conversations predict that the semiconductor market will remain constrained until at least the end of 2023.

Scott says that the cause of the semiconductor shortage is, of course, the epidemic of the new coronavirus infection (COVID-19). Virus outbreaks, labor issues associated with epidemics, and geopolitical uncertainties around supply chains are far-reaching, fueling chip shortages. Scott points out that unfortunately there are no signs of recovery for the foreseeable future, as each point of the supply chain has been so disrupted.

When the shortage of semiconductors is arranged in chronological order, supply and demand fell sharply due to the outbreak of COVID-19 and the shutdown of factories. Here, an abnormal need for semiconductors arose and the demand surged, but the supply could not keep up, resulting in a shortage of semiconductors.

Due to the continued mismatch between supply and demand, the lead time for semiconductors by the summer of 2022 will be at least 40 to 50 weeks, and most will be 50 to 60 weeks, forcing manufacturers to delay product development and sales. This is the situation. As the lead time increases, the price also increases, and it is said that the cost of manufacturing and procurement has to be passed on to the customer in the form of an increase in the price of the product.

In order to meet this demand, semiconductor manufacturers such as TSMC have built new factories, and the US government has enacted the CHIPS law and provided funds to promote public-private efforts. In Japan, TSMC has begun construction of a factory in Kumamoto Prefecture, and on January 13, 2023, it was reported that TSMC was considering ``establishing a second factory in Japan''.

``So far, industries have dealt with semiconductor shortages in short-term ways, with the auto industry cutting high-tech features from new cars and the smartphone industry using semiconductors it had stockpiled when the pandemic hit,'' Scott said. However, this solution is no longer viable and a flexible supply chain strategy based on predictability and communication is needed to navigate parts shortages.”

“The one thing we can say with certainty about the global chip shortage is that no one knows when it will end. It seems that every company is in a similar situation, so it's not something that can be easily avoided,' Scott said, reiterating the importance of a long-term strategy.

Related Posts:

in Hardware, Posted by log1p_kr