Technology that can print electronic boards as if printing a T-shirt logo is about to revolutionize the electronics industry.

Manufacturing next-generation electronics like they are T-Shirts | by Yash Goliya | Jun, 2021 | Medium

https://ygoliya.medium.com/manufacturing-next-generation-electronics-like-they-are-t-shirts-526e8551748b

Membrane switches used for keyboards and RFID used for IC cards are made by printing a conductive material on the substrate. In the conventional technology, silver was the main material used for printing, but according to Mr. Golia, recent technological innovations have made it possible to print materials such as copper, carbon, and conductive polymers in addition to silver. .. In the following movie, you can see how the conductive material ' LF-360 ' developed by Copprint is actually printed on the board.

How to Copprint LF360 --YouTube

Printing of LF-360 is performed in 5 steps of 'stirring', 'printing', 'drying', ' sintering ' and 'relaxation'.

First, stir the refrigerated LF-360 using a machine.

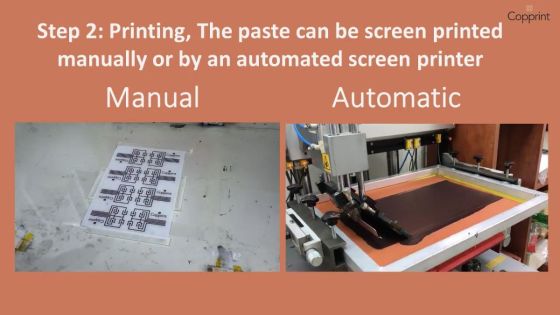

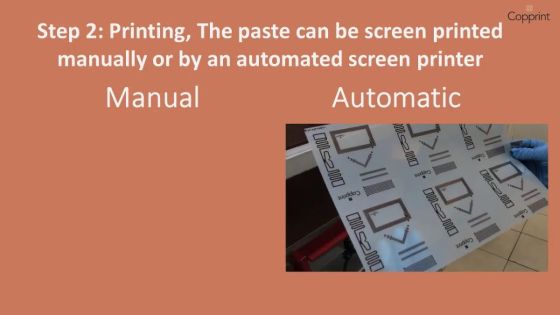

If you apply a thin layer of copper to the substrate by either manual (left) or mechanical (right) with the agitated LF-360 ...

On the manual side, the wiring was printed like this.

The machine is also able to print beautifully.

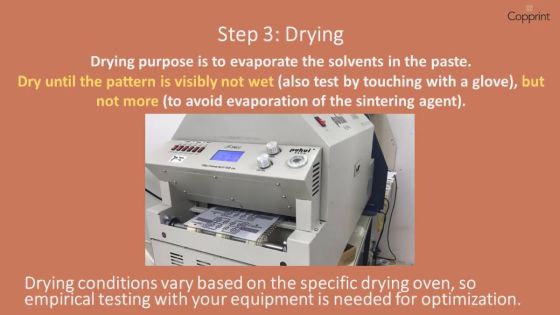

Then put it in the dryer to evaporate the solvent.

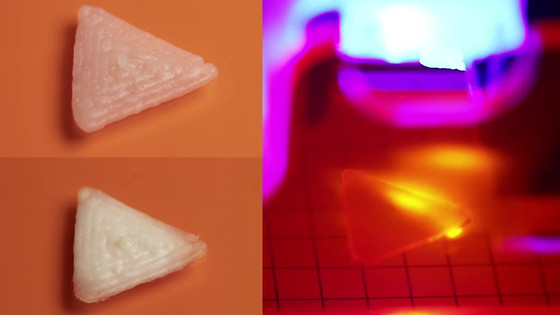

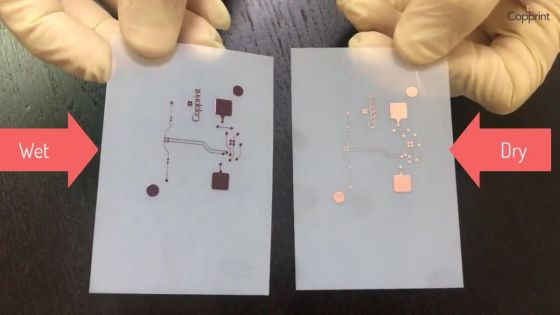

The dried LF-360 (right) looks like this.

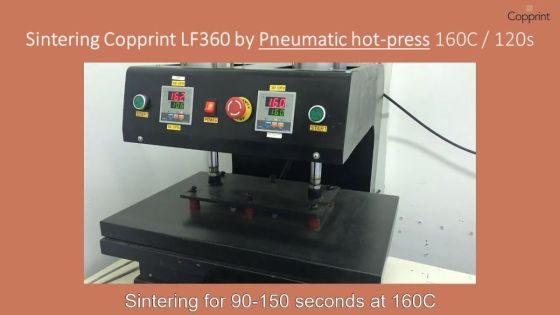

After drying is complete, heat treatment is applied to sinter the molecules to make them conductive. A method using a press machine heated to 160 degrees for heat treatment ...

There is a method of heating with a

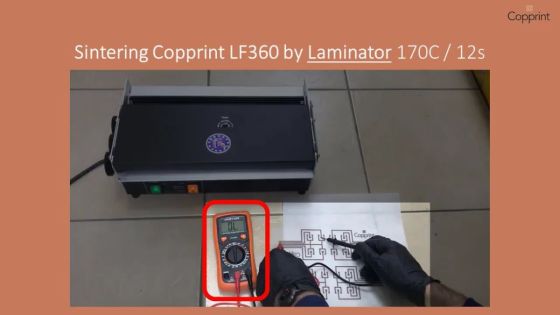

However, if you heat it with a 170 degree laminator for 12 seconds ...

Electricity has come to pass like this. After adding conductivity, it is said that the conductivity will increase if it is left in an environment of 140 degrees for 2 to 3 minutes.

According to Mr. Golia, this printing technology can also create complex electronic devices. For example, in the following movie, you can see how to print a display that can display characters and figures.

Ynvisible InkKit Video Tutorial --YouTube

In addition, it is possible to print parts that emit light as shown below.

Electroluminescent Screen Video Tutorial --YouTube

'The beauty of this technology is its high expandability. For example, the parts manufacturer mekoprint mass-produces healthcare-related sensors using a roll-to-roll method. This technology has just begun a revolution in the electronics industry, 'he said, looking forward to a future in which circuit printing technology can mass-produce inexpensive components.

Related Posts: