Technology to print electrical circuits on skin, bandages, etc. will be developed

By Duke Pratt School of Engineering

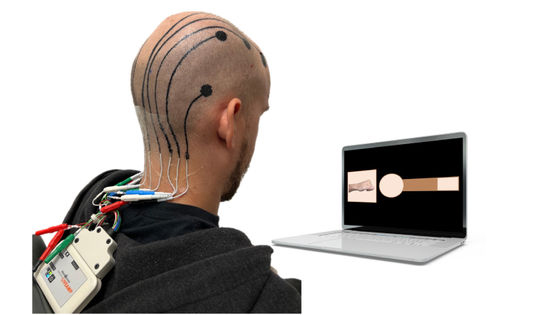

A research team led by Aaron D. Franklin at Duke University in the United States announced a series of research on technologies for printing electrical circuits on surfaces that require delicate handling such as paper and human skin. did. This technology is expected to improve the technique of embedding bandages with highly adhesive electronic tattoos and biosensors optimized for each patient.

Flexible, Print-in-Place 1D-2D Thin-Film Transistors Using Aerosol Jet Printing | ACS Nano

https://pubs.acs.org/doi/10.1021/acsnano.9b04337

Silver nanowire inks for direct-write electronic tattoo applications-Nanoscale (RSC Publishing)

https://pubs.rsc.org/en/content/articlelanding/2019/NR/C9NR03378E

Printed Electronics Open Way for Electrified Tattoos and Personalized Biosensors | Duke Pratt School of Engineering

https://pratt.duke.edu/about/news/print-in-place-electronics

Two research teams, led by Franklin, published two papers each on new technologies in “ printed electronics ”. Printed electronics is a technology that prints semiconductors, circuits, etc. on a substrate, but Franklin says, `` When you say 'printed electronics', you simply load materials and blueprints on a printer, I think it will print out a fully functional electrical circuit, but the research published so far requires the removal and quenching, cleaning, and spin coating to produce thin films. Yes, there was a gap with the image that is generally imagined. '

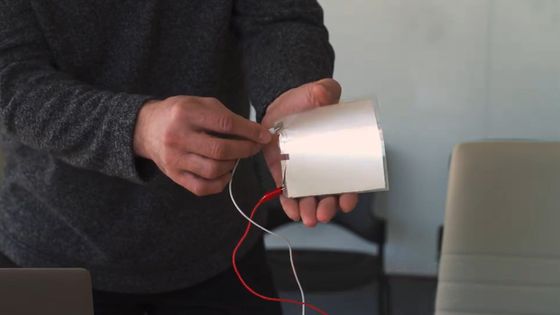

The first paper is a new development of “ink” used in printed electronics. This new ink contains silver nanowires that demonstrate electrical conductivity without the need for additional processing, maintain electrical performance after more than 1000 cycles of 50% bending strain, and within 2 minutes of application. Let it dry.

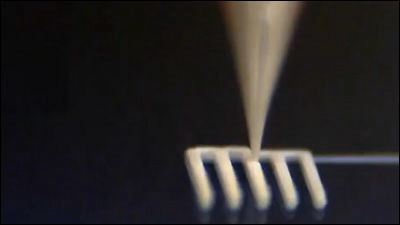

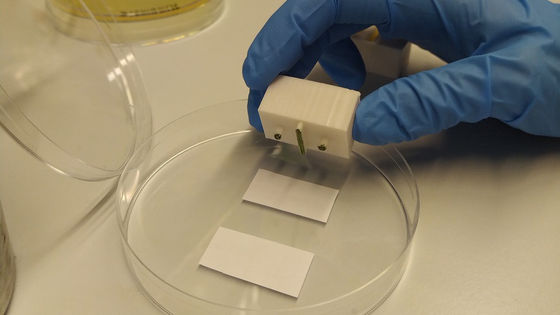

The second paper is a combination of new inks and other printables to print functional transistors. In this technology, a semiconductor strip made of carbon nanotubes is first printed on the bottom side. After the semiconductor strip has dried, it is printed with silver nanowire conductors connected to the edges of the semiconductor strip, an insulator layer is printed on top of the semiconductor strip, and the transistor and silver nanowire conductors are connected and printed.

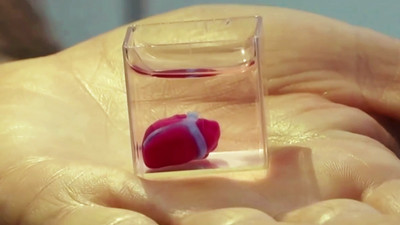

Below is a movie that demonstrates a series of research. The first half of the movie shows the silver nanowire conductor printed on the palmar skin of the little finger. In the latter half, an LED is attached to the tip of the silver nanowire, and the LED lights when energized. Furthermore, it is shown that energization continues even if the finger is bent and stretched.

Fully print-in-place electronics technique from @DukeEngineering is gentle enough to enable electrical tattoos and customized biosensor bandages https://t.co/9PY4EQXVa3 pic.twitter.com/4oLOyGnGGU

— Duke Engineering (@DukeEngineering) October 3, 2019

In the conventional technology, in order to print a circuit on the skin as in this demonstration, processes such as washing away unnecessary materials and baking were essential. However, with this new technology, such a process is unnecessary, and the temperature required for processing is lower than the conventional technology. Franklin said, “This time, we announced the first technology that fits the 'printed electronics' people imagine.” “Nurse prints a biosensor suitable for the patient on the bandage on the spot. Think about it, this technology is one step closer to that future. ”

Related Posts:

in Science, Posted by darkhorse_log