Succeeded in developing technology to 3D print metal structures on a scale of 40% conventional

Conventional 3D-printed metal structures consisted of a minimum of about 100 microns, but a research team led by

Additive manufacturing of micro-architected metals via hydrogel infusion |

https://doi.org/10.1038/s41586-022-05433-2

New Process Allows 3-D Printing of Microscale Metallic Parts | www.caltech.edu

https://www.caltech.edu/about/news/new-process-allows-3-d-printing-of-microscale-metallic-parts

3D printing of metal, also known as additive manufacturing, can create structures that cannot be manufactured by traditional metal forming methods such as casting or inkjet molding , and can produce structures on a scale as small as about 100 microns, equivalent to the thickness of two sheets of paper. increase.

However, the 3D metal printing process is said to reduce the printable scale due to the high thermal conductivity of the metal.

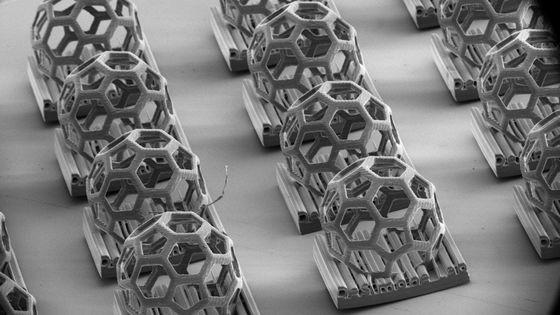

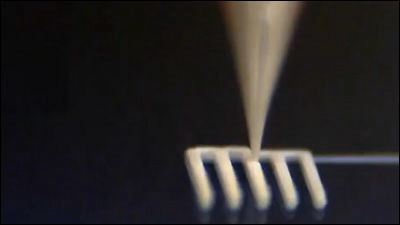

Therefore, unlike the conventional method of directly 3D printing metal, the research team of Max Saccone and others at the California Institute of Technology 3D prints hydrogel and uses the hydrogel as a scaffold `` hydrogel injection additive manufacturing process ( HIAM) ” and announced on October 20, 2022.

Hydrogel, which is insoluble in water, is used for soft contact lenses, etc., and has the property of hardening due to a chemical reaction when irradiated with low-power ultraviolet rays. By repeating this process, the desired fine shape can be formed.

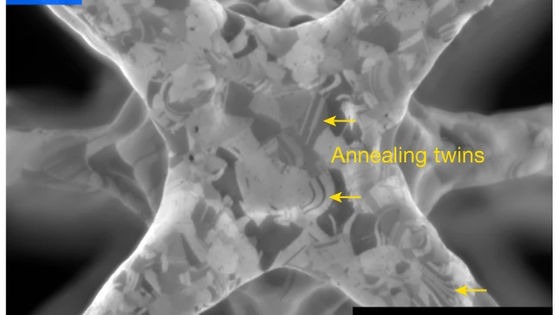

Next, the hydrogel is infused with a metal salt dissolved in water to permeate the hydrogel with metal ions. Then, burning the hydrogel causes the entire structure to shrink, making the metal structures smaller. The researchers report being able to 3D print metal at a scale of about 40 microns, less than half the width of a human hair.

HIAM is also said to be able to process a variety of metals with minor adjustments to the process, and the research team created 3D printed structures made from various metal alloys such as copper, nickel and silver during development. I'm here.

Forming metal with HIAM has potential benefits for the automotive and aerospace industries and biomedical devices. 'We can create metal materials in a much more environmentally friendly way than we can.'

Related Posts:

in Science, Posted by log1r_ut