An on-chip water cooling system will be developed that can cool chips directly with liquid with up to 50 times the efficiency of conventional products.

The heat generated by electronic devices is a major problem, especially for reducing the size and packing as many transistors as possible in the same chip. Usually, the chip design and the chip cooling system are independent and separate. But now, researchers

Co-designing electronics with microfluidics for more sustainable cooling | Nature

https://www.nature.com/articles/s41586-020-2666-1

Transistor-integrated cooling for a more powerful chip

https://techxplore.com/news/2020-09-transistor-integrated-cooling-powerful-chip.html

Self-cooling microchip provides a tiny solution to a giant problem

https://www.inverse.com/innovation/self-cooling-microchip-moores-law

According to a report from the United States Department of Energy, US data centers are expected to consume 73 billion kilowatt hours of energy in 2020. And every time it consumes 1 kilowatt hour of energy, it needs 2 gallons (about 7.6 liters) of water for cooling.

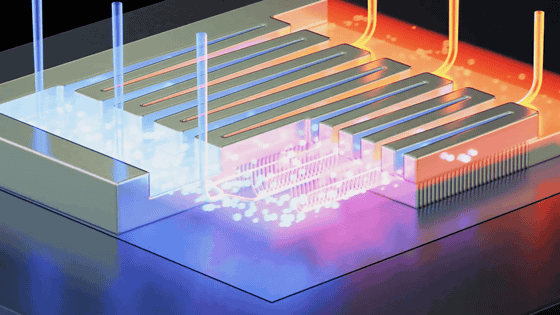

EPFL researchers have developed the cooling system shown in the movie below.

POWERlab Matioli --YouTube

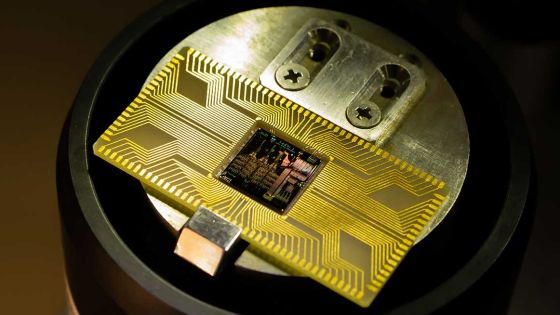

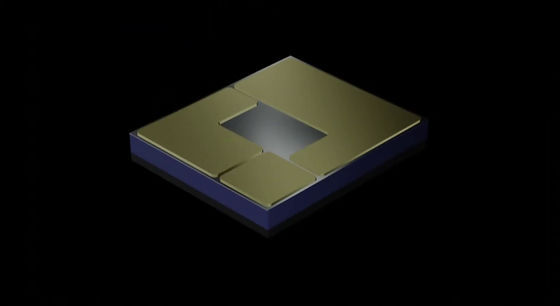

Chip body with multiple dies

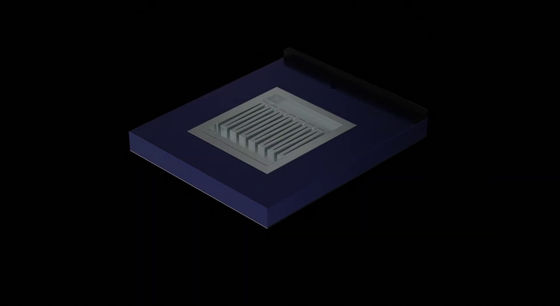

When you turn the tip over, it looks like this.

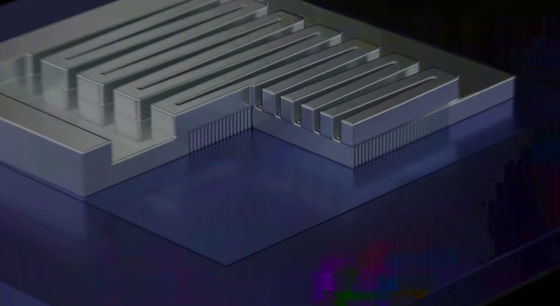

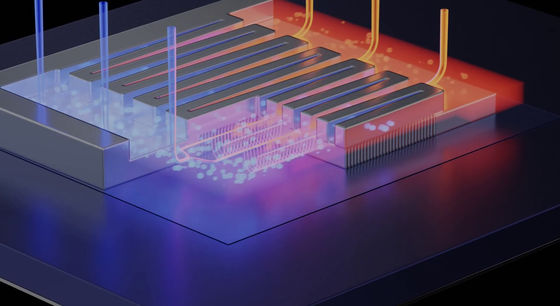

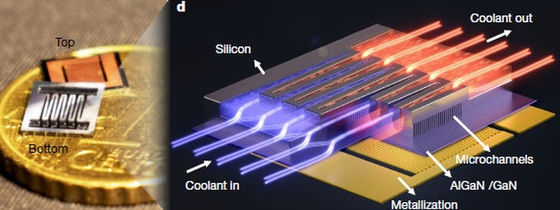

If you remove the bottom of the chip base, you will see a microfluidic channel inside the chip substrate that provides a cooling mechanism.

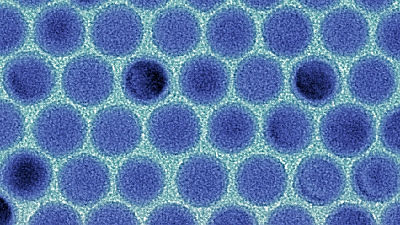

Complex grooves are engraved on the microfluidic channel.

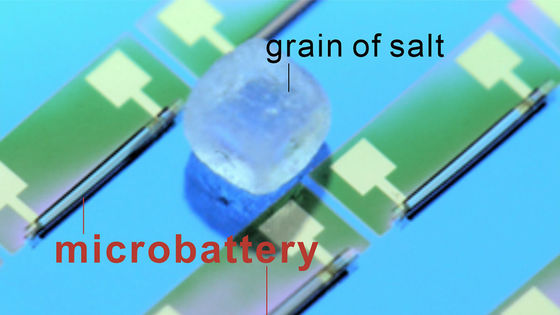

A coolant is run between the grooves to cool the chip properly and prevent heat from being transferred to the entire device. According to researchers, it was possible to achieve a cooling efficiency of up to 50 times that of the conventional model. Deionized water that does not conduct electricity was used as the coolant.

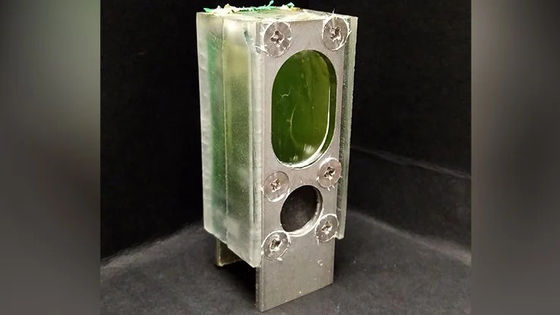

The left of the image below is the actual cooling system. Stick it on a silicon die and cool it directly.

However, the research team has listed it as a future research topic because the pursuit of adhesives for fixing the cooling system and materials used for the substrate surface is insufficient. The researchers also say that long-term stability is also required due to concerns about flushing the coolant very close to the chip.

'This cooling technology has the potential to make electronics even more compact and significantly reduce energy consumption around the world,' said Ellison Matioli, a professor of EPFL engineering who is part of the research team. We have shown that it is possible to create an ultra-compact power converter with a single chip by eliminating the need for an external cooling device. '

Related Posts: