BMW and MIT jointly developed 'liquid 3D printer' which outputs telescopic silicon into a tank

The design department of the automaker · BMW and the Massachusetts Institute of Technology (MIT)'s Self Assembly Lab (self-organizing laboratory) jointly " 3D printing technology that can inject liquid silicon into the gel and output it in any form " It has announced that it has developed. While conventional 3D printers stack the resin over the flat layer using the support material, it is possible to output the free shape with the explosion speed without the support of the new liquid 3D printer .

Large-Scale Rapid Liquid Printing | 3D Printing and Additive Manufacturing

https://www.liebertpub.com/doi/abs/10.1089/3dp.2017.0037

Liquid to Air: Pneumatic Objects - Self-Assembly Lab

https://selfassemblylab.mit.edu/new-gallery-1/

Liquid Printed Pneumatics - Self-Assembly Lab

https://selfassemblylab.mit.edu/liquid-printed-pneumatics/

You can check the appearance of actually outputting with a liquid 3D printer and the state of expanding the outputted silicon parts on the movie at the following site.

Liquid Printed Pneumatics - Self-Assembly Lab

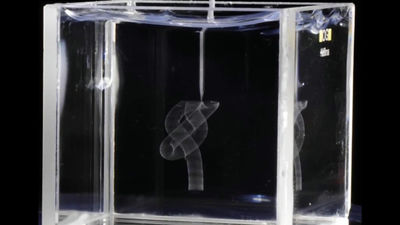

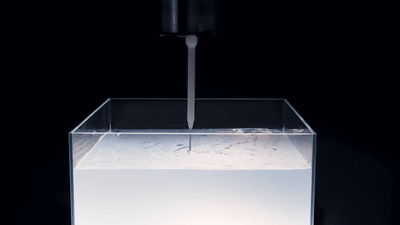

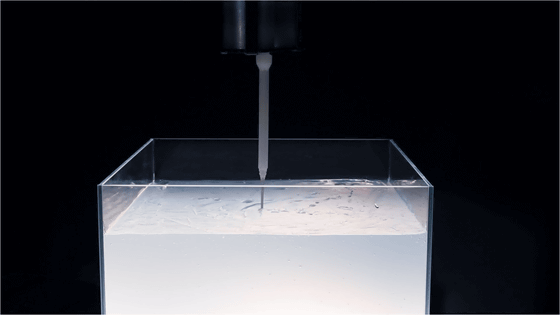

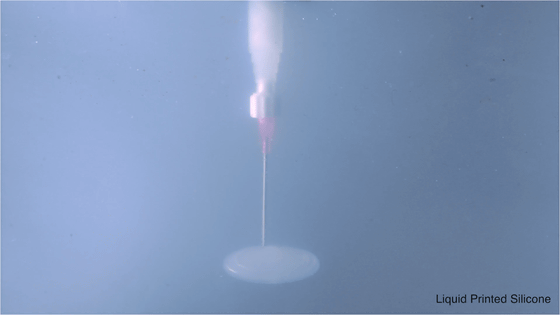

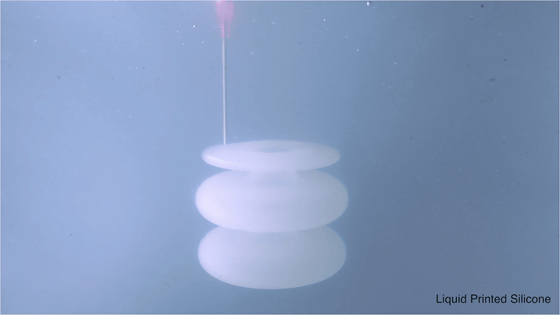

The robot arm inserts the needle for injecting silicone ink into the aquarium filled with granular gel. The granular gel not only supports fluid silicone ink but also has the role of curing silicon.

Silicon is squeezed out from the tip of the needle, and pump-like parts are formed in the aquarium as it gets wet. The output of the new liquid 3D printer is very fast, depending on the size, all output takes about several minutes.

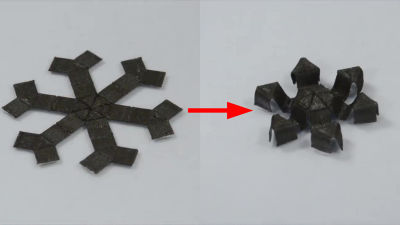

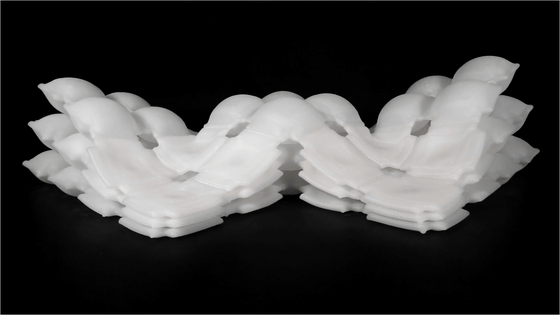

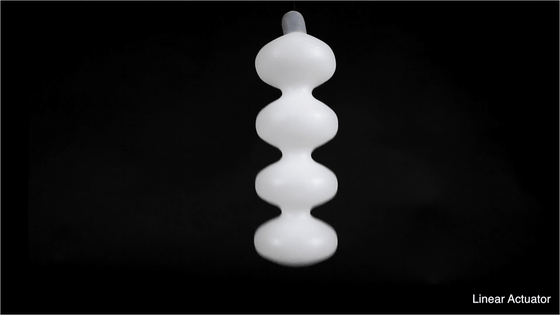

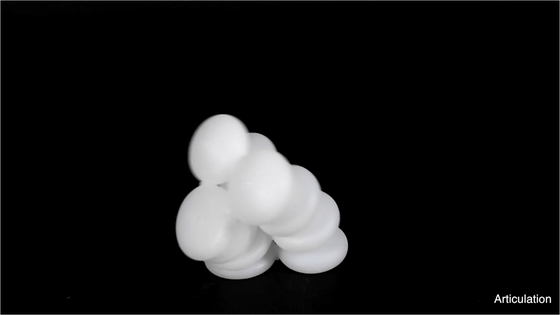

Completion of a pump that expands and contracts vertically when pneumatic pressure is sent to the inside of the part in a blink of an eye.

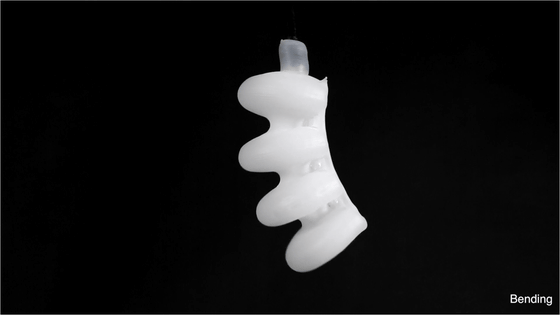

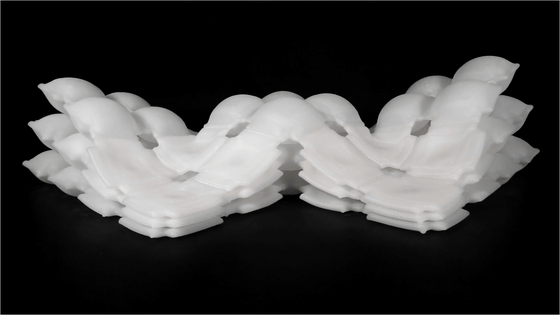

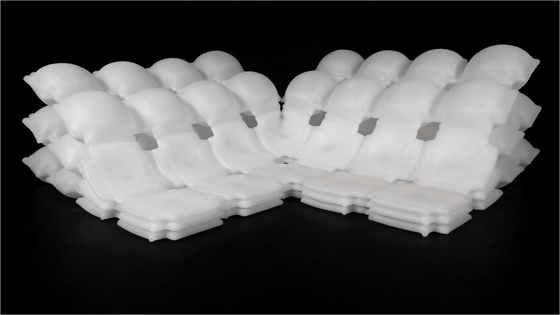

If you change the shape, you can also make a pump that stretches and contracts while it is bent.

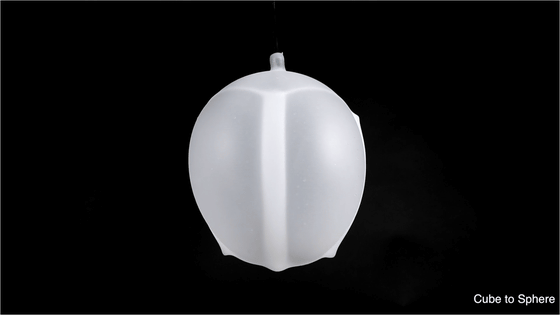

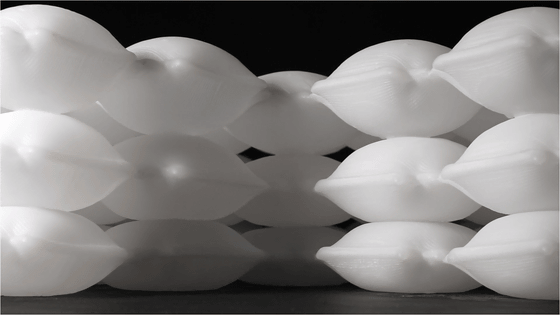

This is cubic silicon plus air pressure. The accuracy of the liquid 3D printer seems to be quite high, there is no distortion in shape and the direction of bulging is not biased.

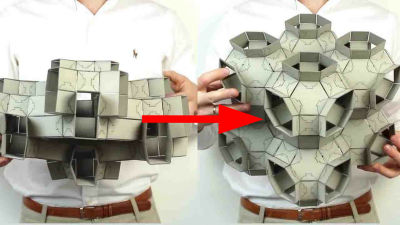

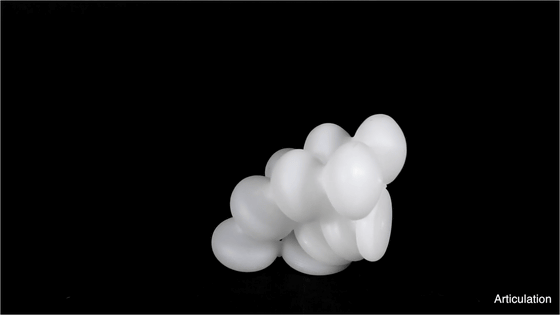

By combining multiple pumps and adjusting the air pressure, you can expand and contract in a free direction.

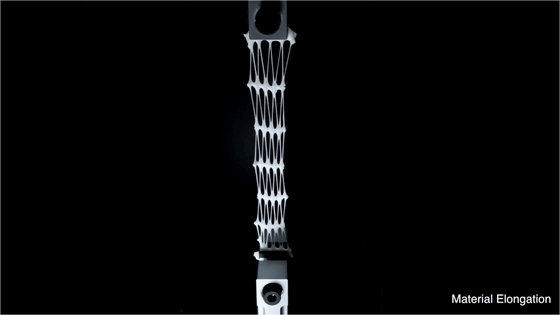

The silicone material used for the liquid 3D printer is rich in elasticity, and even if pulling a mesh-like silicon with a machine, it does not appear to be torn.

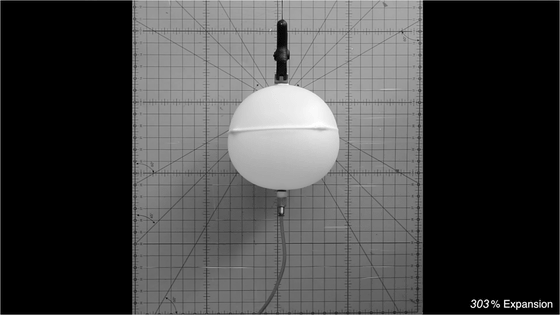

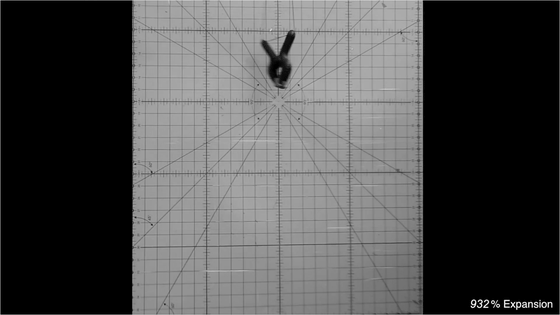

When balloon shaped silicon is output and air is injected to the limit ......

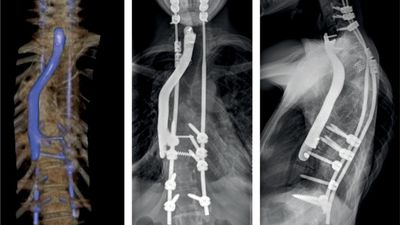

It burst at last when the expansion rate exceeded 900%. The strength of silicon used in liquid 3D printers is considerable, and it seems that they can be expected to be applied to parts of cars such as airbags and medical instruments.

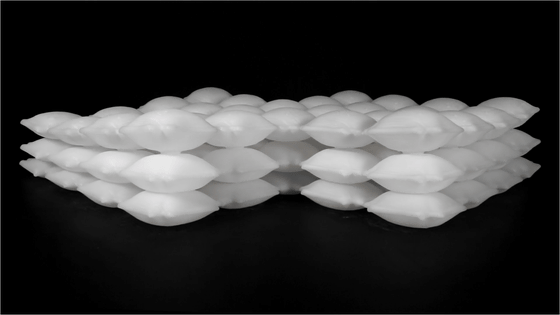

Silicon seat which was petit ... ...

When air is sent in, it is as thick as a mattress.

In the movie, there was also a scene that adjusts the air pressure so that a sheet made of silicon can be washed like a living thing.

MIT used this liquid 3D printer to output a lamp shade and a vase based on the design by a Swiss designer and also had an exhibition of "output" that was output.

Related Posts:

in Hardware, Posted by log1i_yk