A patch for ultrasonic examination that can cope with complex curved surfaces such as engines and turbines has appeared

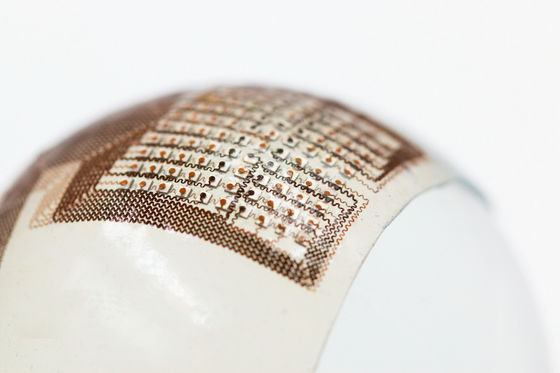

University of California, San DiegoResearch team such as Professor Shen Shu of Nano Engineering of Nanotechnology will examine the strength of structures etc.Ultrasonic examinationWe developed a flexible patch that can be used for. With the appearance of this patch, it is said that ultrasonic inspection can be performed on complex shaped objects such as engine parts and turbines, which had been considered difficult until now.

Flexible Ultrasound Patch Could Make it Easier to Inspect Damage in Odd-Shaped Structures

http://ucsdnews.ucsd.edu/pressrelease/flexible_ultrasound_patch_could_make_it_easier_to_inspect_damage_in_odd_sha

Ultrasonic patch is an inspection tool for checking the presence or absence of damage directly under the surface of the patch after sticking to a machine or a construction part. Since the surface for inspection was flat and rigid, the probe used for conventional ultrasonic examination was subjected to ultrasonic examination for nonplanar objects such as "wavy" and "curved" I could not do it effectively. Professor Shu says, "In modern times where there are many nonplanar surfaces, this is a considerable limitation."

Co-researcher Professor Francisco Lanza di Scalea of Structural Engineering at the University said, "It is extremely important to measure the strength of the most forceful part of the structure, such as bent pipes and horns, but it is rigid, Existing probes with flat contact surfaces are not suitable for imaging these internal defects. "

When inspecting a nonplanar object with a conventional probe, a virtual plane was made using gel and oil to improve contact with the probe. However, if there are too many gels and oils, there are problems such as part of the signal being blocked, so there is a problem that efficient inspection can not be done. Also, since the probe itself was also large, it was not practical for inspecting parts that are difficult to contact such as curved pipes. Therefore, Professor Shu and his team developed ultrasonic patches that are flexible and independent of the ground plane.

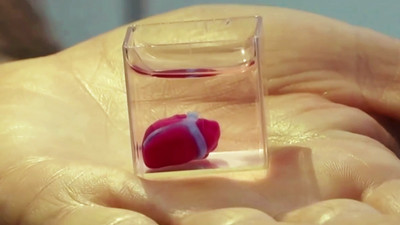

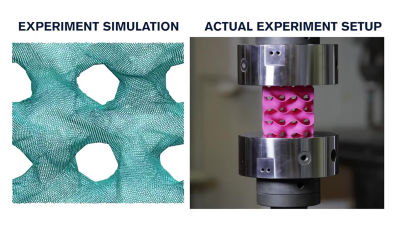

This probe follows a pattern called "island bridge" structure, and the substrate and copper wire are arrangedsiliconeElastomerIt's a patch. In this patch, regularly arranged electronic components (islands) are connected by a spring-like copper wire (bridge). The island has electrodes and devices called piezoelectric transducers, and ultrasonic waves are generated when electricity passes through. Also, since the bridge is springy, it can be extended and bent, and it can be contacted with many non-planar surfaces.

In order to confirm the practicality of this patch, the research team, Professor Shu, et al. Conducted an inspection with an aluminum block with a wavy surface. In addition, the defective block is used for the block to be inspected. The research team stuck a patch on all sides and performed an ultrasonic examination and when imaged it was able to confirm the presence of 2 mm wide holes and cracks.

According to Honjie Hu, a co-author of the paper, who specializes in material engineering at the university, he says, "This patch is used for various parts and structures such as engines and airplane wings and continues to be cracked It is very wonderful to monitor it. "

The developed patch is said to be in the demonstration stage of the concept, so it can not be imaged in real time at the time of article creation. In addition, we need a power supply and a computer to process the data, Professor Shu said, "In the future, to make wireless and real-time imaging and imaging possible, patch power supply and data processing functions I am planning to add it to this. "

Related Posts:

in Hardware, Posted by darkhorse_log