MakerBot releases a new output algorithm "MinFill" that can reduce 3D filing speed by 30% and reduce filament usage by 30%

An output algorithm that can increase modeling speed by 30% and reduce filament usage by 30% without changing existing 3D printer material "MinFillMakerBot, a 3D printer maker, has developed. MinFill is compatible with version 2.0 of free 3D printing software "MakerBot Print".

MakerBot MinFill 30% increase in shaping speed, 30% filament saving

http://makerbot.co.jp/jp-minfill.html

You can see how much faster MinFill is than the conventional output format by looking at the following movie.

MakerBot | Introducing MinFill - YouTube

MakerBot has newly added a mode called "MinFill" to 3D printers.

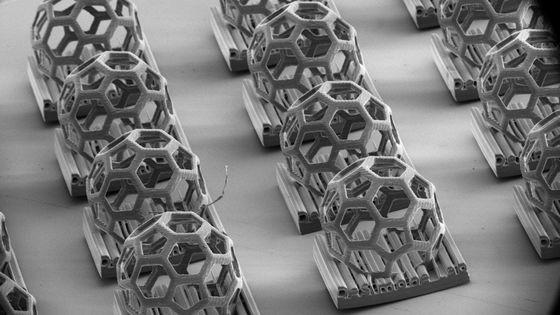

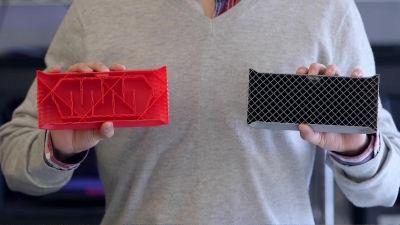

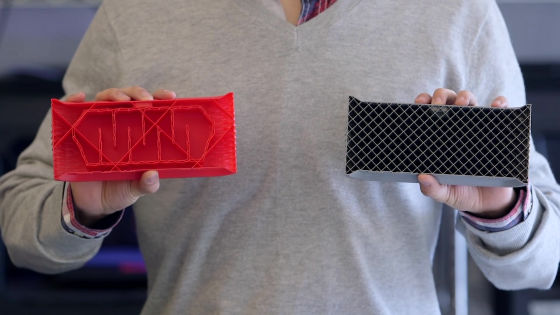

It is a part made with MinFill on the left and a part made in the conventional form on the right. The internal three-dimensional structure seems to be different.

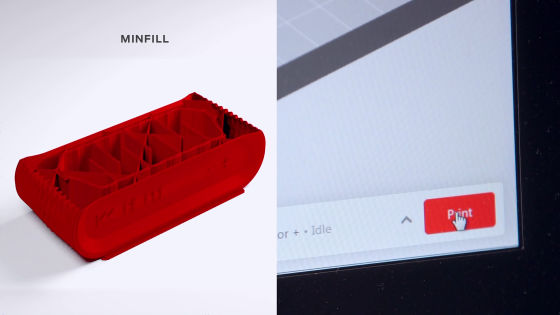

MinFill is a software improvement that changed the algorithm of the output method without changing the material such as filament.

For items manufactured with a 3D printer, an exterior part called "shell" ......

It can be divided inside called "infill". 3D objects are made by combining shell and infill.

In the conventional output method, the infill has the same structure in the vertical direction, whereas in MinFill it is possible to increase the molding speed by changing the three-dimensional structure of the infill.

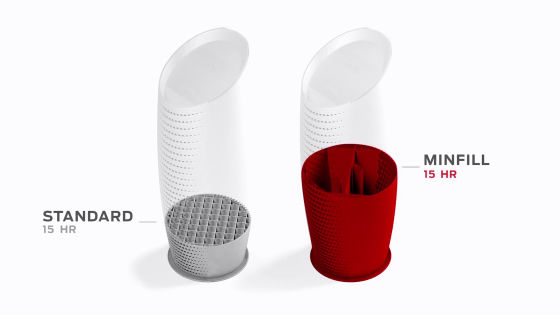

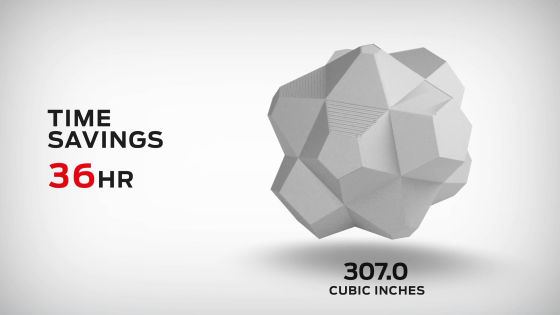

At the same time that the output speed is increased by 30%, the filament usage can be reduced by 30%.

In MinFill, we analyze the three-dimensional structure and output it to the part where the intensity is required, but on the other hand, it does not output to the part irrelevant to the intensity. Although this can increase the output speed and reduce filament usage, the strength of the finished object will not change from the conventional output method.

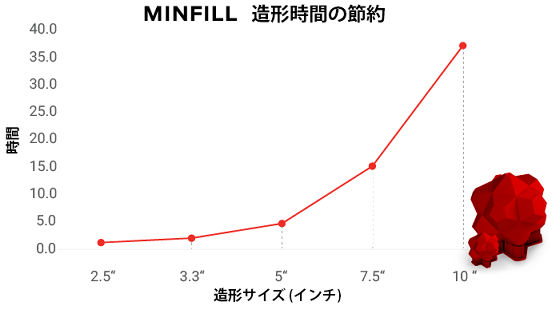

MinFill demonstrates its power as the size of the object increases.

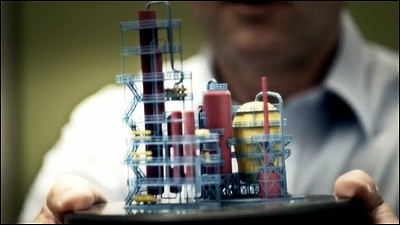

Also, as the shaped object with a complicated shape, the effect of increasing the molding speed seems to be high.

By using MinFill, it is possible to dramatically shorten the time of concept confirmation work that is performed iteratively at the initial stage to evaluate basic items such as overall shape, size and balance of the product, and speed up the design process MakerBot says. MinFill, which is effective in manufacturing prototypes whose structural speed is more important than structural strength, can be used with Makerbot's output software "MakerBot Print" Ver. 2.0.

MakerBot Print Software | MakerBot

https://www.makerbot.com/print/

Related Posts: