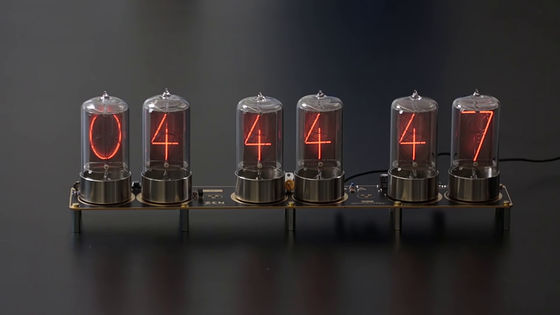

Until "Nixie tube" to display numerals with soft light

It is housed in a glass cylinder and displays numerals from 0 to 9 with orange soft light like a bulb "Nixie tube"Is a device of" extreme analog "that has been more than 50 years since its birth, but even in the 21st century of digital prime, people fascinated by its unique texture will not fail. A movie that tracks until such a Nixie tube is made has been created.

The Art of Making a Nixie Tube - YouTube

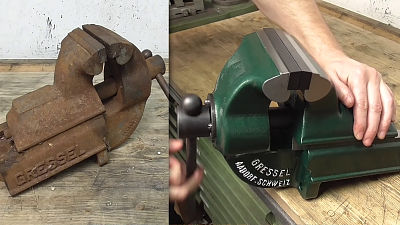

Daribor Farney, who is operating a Nixie tube factory in the Czech Republic, explains the production scenery of the Nixie tube. Mr. Farney was also one person fascinated by the Nixie tube, but in the world it is already shocked by the fact that there are few plants to make Nixie tube, and to establish himself Nixie tube factory. And nowDalibor FarnyWe launched the brand, developed products such as watches using the Nixie tube, it seems to be preparing for sale.

One of Dalibor Farny brand products, "Zen Nixie Clock". It looks like a 6-tube timepiece but it looks retro, but what inside can be said to be a modern expression with internet connection function and so on. The price is 1685 dollars (about 170,000 yen).

This watch also uses the newly developed Nixie tube "R | Z 568 M". Mr. Farney has newly designed his own Nixie tube after handing out old materials.

It was in 2011 that Farney met Mr. Nixie tube. He seems to have decided to produce himself immediately, but Mr. Farney who does not have the experience of Nixy tube making and facilities also gathered the equipment and started from learning the manufacturing method.

At first I was making a Nixie tube at home but as soon as it got narrowed, I decided to build a dedicated factory in the garden.

Carrying dedicated equipment by truck ......

A new building is also built.

Mr. Farney, who made a prototype here, said he exhibited the completed prototype at overseas exhibitions and others.

After that, we decided to borrow some corner of the castle in the local to do the actual production.

We prepare dedicated equipment and build mass production system.

In this way, Dalibor Farny brand Nixie tube has been produced.

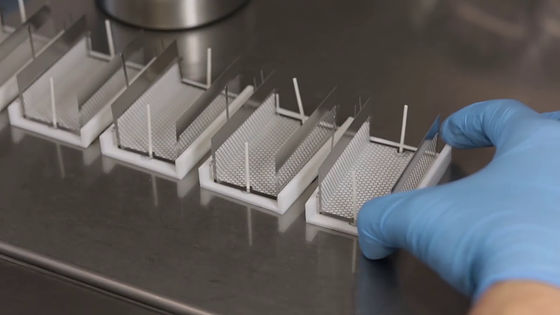

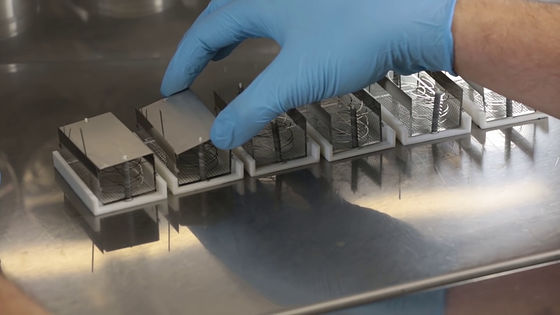

It also contains actual manufacturing scenery. First of all, washing metal parts that are materials.

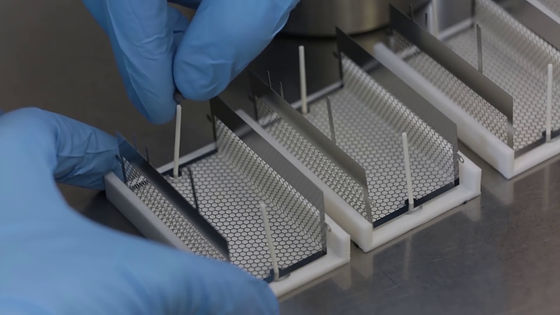

Put metal parts in a mesh-like vessel ......

Use water diluted with detergent solution and ultrasonic cleaner to remove the dirt on the surface.

After removing dirt, do "rinse" several times with water ... ....

"Surface stabilization processing" to prevent surface change is performed.

Finally rinse again ......

Dry in the oven. This completes the processing of parts first.

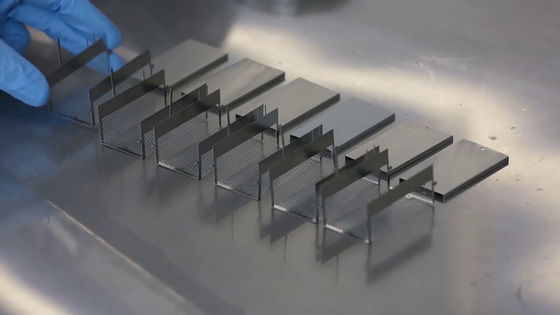

Stacked parts. We will start machining parts from here.

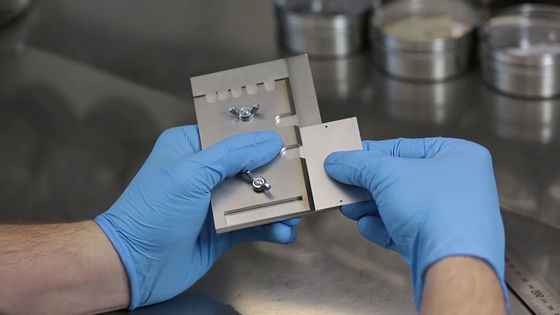

Place the plate-like parts in the equipment ...

Using a gold ruler, fold the edge of the part 90 degrees to "ぐ っ っ". This was done in two places on the left and right.

You can make flat U-shaped parts like this.

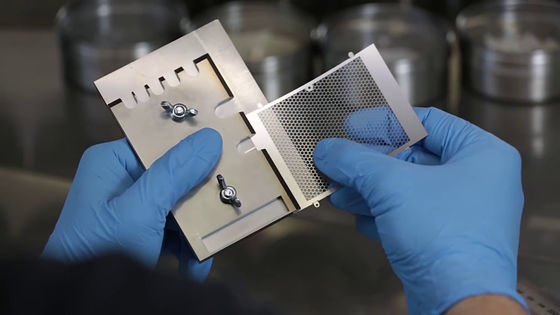

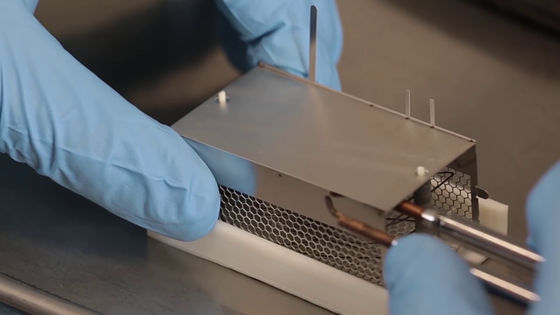

Next time, fold the mesh plate with the fine holes open in the same way ......

Also prepare U-shaped parts here.

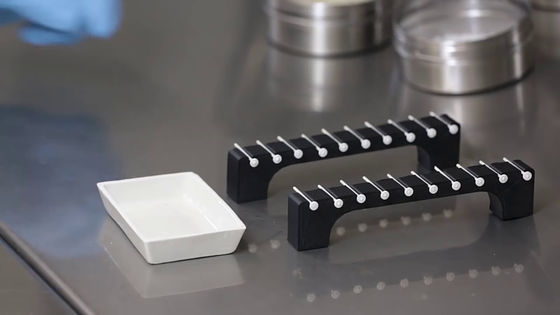

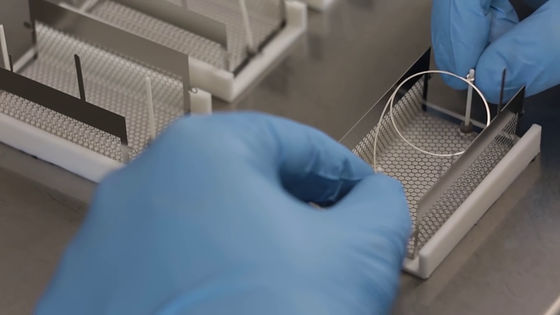

Next, I will make a pedestal to fix the parts. Pass the round parts through a white pottery stick and apply the solution with a brush and bond.

A white part like a stitch is made.

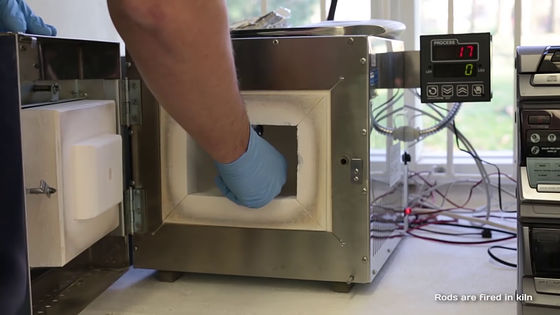

Put this in an electric kettle and bake it firmly.

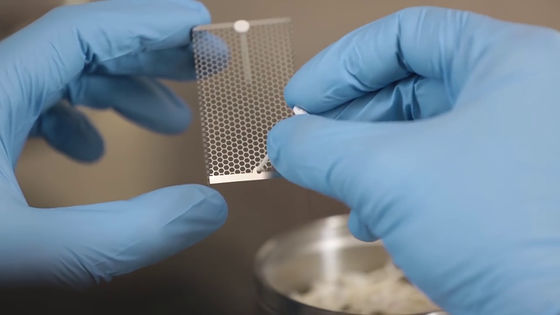

Pass the baked parts through the holes in the mesh plate ......

Assemble it like this. Seems to put some parts on top of this bar from above.

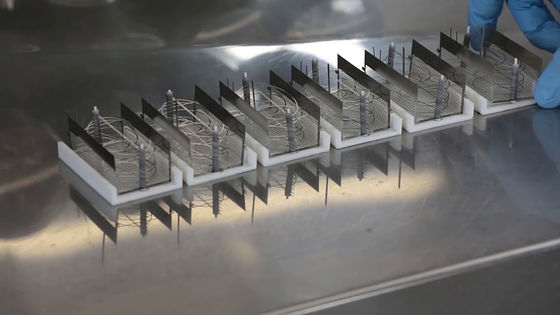

Place a black ceramic insulating spacer ......

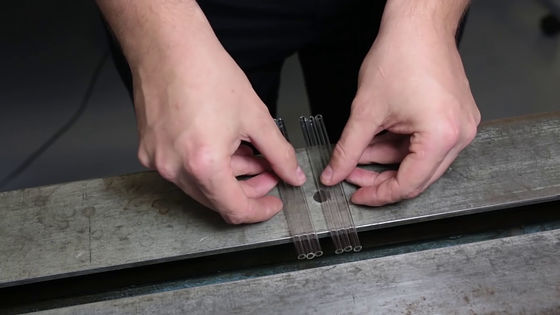

Place numbers on the display plate in order. A spacer is sandwiched between the plates so that they do not touch each other.

A unit with numbers from 0 to 9 was created. It is a series of fine manual work.

Next, overlay the iron plates made by folding first ... from the top ...

Firmly weld the upper and lower plates with a spot welder. This will not cause the numbers plates etc to fall apart.

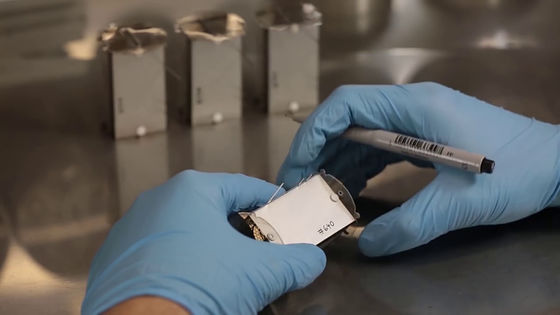

Lastly, if you put a glass round plate on the top and bottom of the unit, the unit to display the numbers is almost completed.

Write the serial number.

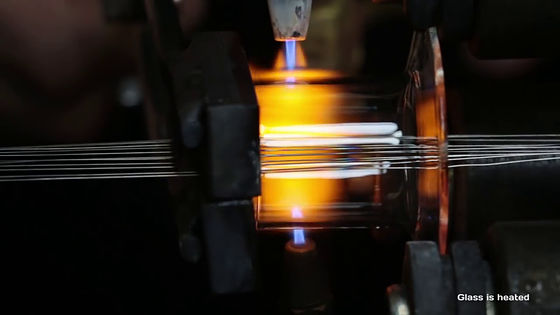

Once the display unit is completed, we are now preparing a glass tube for the Nixie tube. First of all, mold with a thin glass tube heated ... ...

Manufacture such parts with flat flanges.

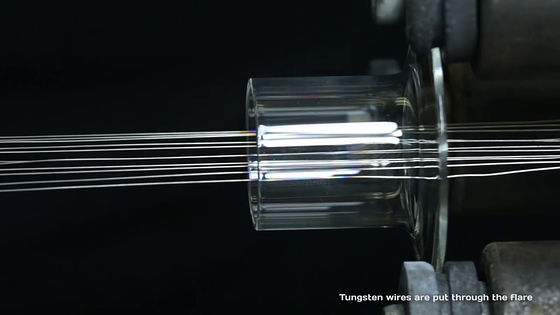

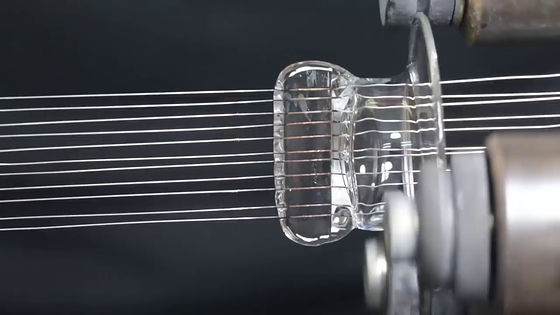

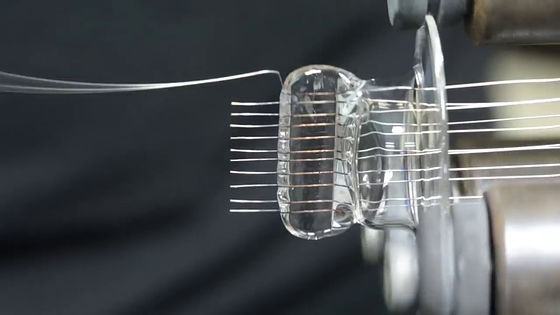

Pass 11 wires of tungsten through here. This "eleven" means a total of eleven, 10 for the plate from 0 to 9 and 1 for the common anode electrode.

After passing the electric wire, heat the glass tube again ... ...

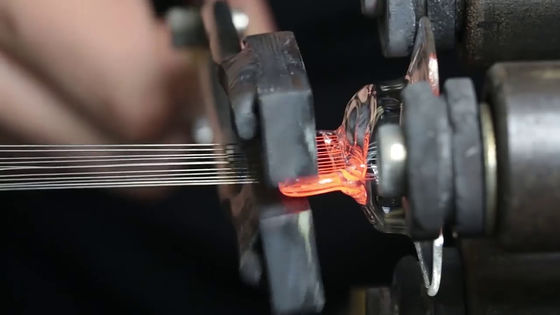

With pliers (pliers) you can grasp "Mu guc".

By repeating this process, we will make up the part in which the wire is hermetically sealed inside the glass.

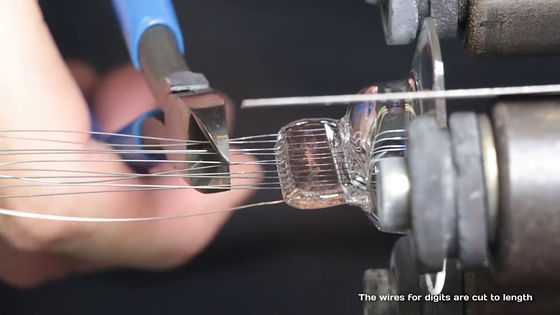

Cut the wire which is too long here.

Leave the wires for the anode long in the folded state.

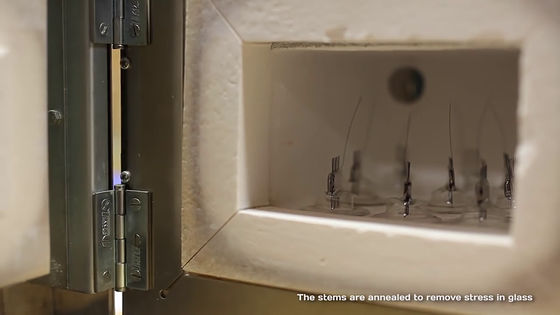

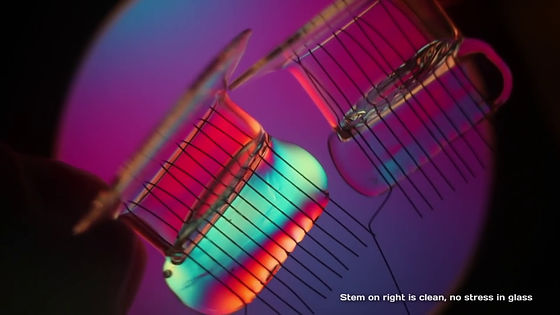

In this state, put the parts in the electric kettle, add heat, and do "annealing". By doing this, we eliminate the "distortion" that occurred when the glass was thermally processed.

Looking through the light of the special instrument "polarizer", the glass part before processing (left) looks rainbow-colored, and after processing (right) it turns out that it is transparent. This distortion is called "residual stress", which is caused by solidification with force applied to the inside of the part due to cooling during thermal processing, which may cause damage later. In order to remove this residual stress, it is the process of applying constant heat to soften the glass and eliminate force distortion.

When processing is finished, check whether the wire is sealed properly.

Place the glass parts on the cylinder on which the rubber ring is placed, remove the internal pressure and adsorb.

In that state, helium gas is blown from the top, and it is checked whether gas does not enter inside the cylinder. It is an important process in guaranteeing the performance of the Nixie tube where sealing is required.

The parts that passed the inspection are cleaned and proceed to the final assembling process.

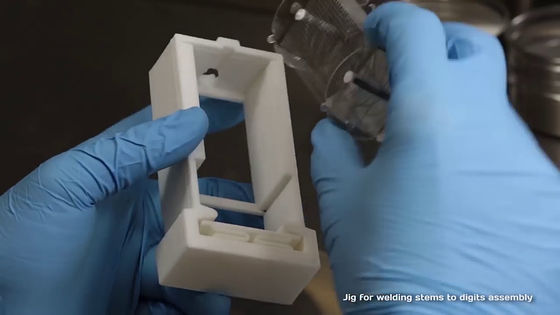

Combine the display unit and the glass base.

The display unit and foundation parts are attached to a dedicated jig (jig) ......

With spot welding machine, firmly weld each other's wires.

The two parts are united with this. When this whole unit is contained in a glass tube, the Nixie tube is completed.

We are going to finish work and go into manufacturing glass tubes that contain units. First of all, a thin glass tube for extracting air is prepared.

Next, a thick glass tube is prepared. This is the material that will become the tube on the outside of the Nixie tube.

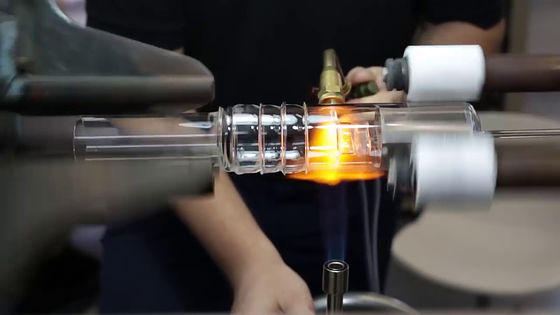

Rotating a thick glass tube, burning with a burner ......

The molten portion obstructed arbitrarily, and a glass tube like a test tube was completed.

Drill a small hole in the occluded part and cover it with a thin glass tube prepared.

It is a bit hard to see, but a part with a glass tube like straw on the end of a thick glass tube has been made.

Insert the previously assembled unit into this glass tube.

And, the part which becomes the butt of the Nixie tube is cooked with a burner and heated ... ...

Wait a minute ......

The petun and the glass broke, the outer glass tube and the base of the glass of the unit sticked together, and it became one glass tube.

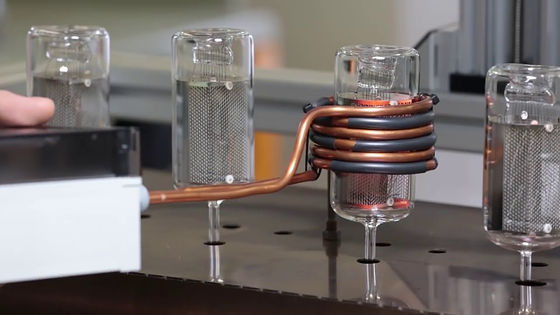

Lastly, I installed a thin tube attached to the vacuum machine and suck out the inside air.

In addition, by heating the metal of the unit with an induction heater, we perform the process of discharging the residual gas adhering to the metal.

Inflated with very small amount of neon gas and argon gas with the air removed. This means that the Nixy tube can emit more efficiently.

When processing is completed, cut a thin glass tube by heating. At this time, due to the internal negative pressure the pipe will occupy arbitrarily, so air does not flow backwards.

As a finish, install heat shrinkable tube for insulation on 11 electric wires ......

Attach this base plate. This is the electrode part for attaching the Nixy tube to the connector on the board of the equipment.

Place the Nixie tube on the electrode set in the jig ... ...

Solder the wires one by one.

The completed Nixie tube carries out a break-in process called "aging" ... ...

To the finish, excised the glass tube which remained in the top part beautifully.

In this way, the historical Nixie tube is manufactured.

Related Posts: