"The Birth of a Barrel" that understands the process of making that "barrel" that puts whiskey

A white label of NO.7 on a black label is impressive whiskey "Jack Daniel"Is a liquor that has been loved for so many years that he can not know the exact birthday, and the origin of NO. 7 was that Jack Daniel of the founder had seven girlfriends, or he wrote" J " Various speculations such as the character seemed to be 7 or simply lucky number are fluttering, but as the history is long, there are also extraordinary commitments in its manufacturing method. A movie that shows how Jack Daniel's "barrel" is made is "The Birth of a Barrel". From the selection of wood, the way barrels are made through processes such as being combined by barrel craftsmen 's hands and carefully burning the interior is as follows.

The Birth of a Barrel on Vimeo

The white oak wood pieces that are piled up

Although it is well packed outdoors ... ...

Also in the factory.

Unloading at a stroke with a forklift.

I will put it one by one on the conveyor line.

Working while directing a gigantic fan towards you.

The wood pieces are carried one by one ... ...

The wood chips are sorted out in the hands of the next person in charge.

Remove the wood piece after sorting from the line and move it.

When opening a hole in the side of a piece of wood with a machine ......

I will return it to the line again.

Insert bar-like parts into the hole.

Five pieces together ...

press.

Five pieces of wood to one board.

I will cut it to become a disk shape.

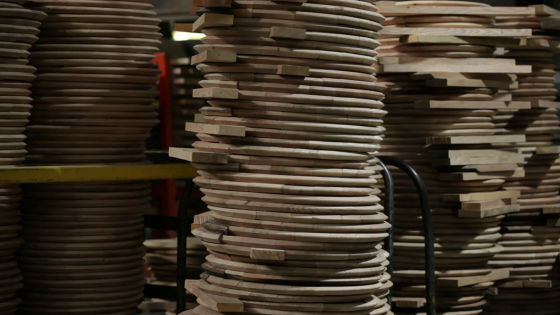

The part of the outer lid called barrel mirror (Teru Kagami) was completed.

A tremendous amount is superimposed.

In the next process the letter "DANGER" ....

The barrel mirror goes through the fire which burns.

It looks like the outside is not burnt.

Carrying by line ......

Completion by stacking.

Again a bunch of wood chips appeared.

It is arranged in a radial pattern.

I will keep the piece of wood in the iron frame.

Just draw a circle.

Fix it so that the wood pieces will not be scattered ... ...

Turn over and into a machine that steams.

I will steam the side of the barrel.

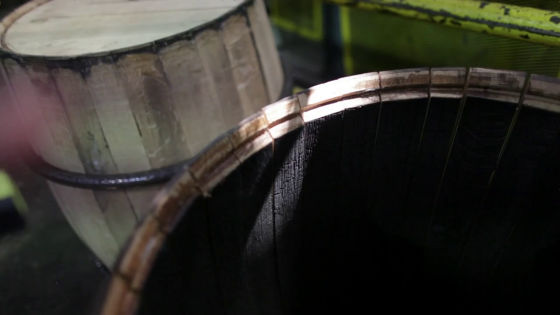

Iron-made hoops that are arranged side by side.

I will firmly snap into the barrel with a handkerchief.

Finally it looks like a barrel.

Do it ... ....

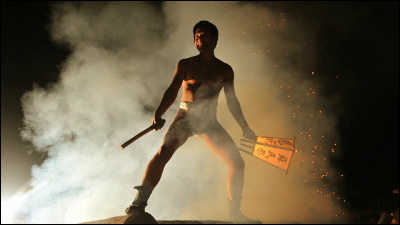

I put it on fire.

A fire is spurting out of the barrel.

If we put out the fire ... ...

The inside is black. This is a process carried out to make the natural sugar contained in the tree caramelized. The rich amber color of the whiskey, distinctive flavor, and flavor are brewed out from the baked oak material.

It has completely carbonized.

Disk shaped barrel mirror made earlier reappears.

I will put it in a barrel.

Next I will put the iron band.

Attached using a machine.

A man with a serious look.

I will fix the iron band firmly in the barrel so that the barrel will not become loose.

And on the side of the barrel ......

I will open a dowel hole.

Stopper ... ...

Apply water and air pressure for airtightness test. After passing the inspection without any problem ......

Finally, I will press the "Jack Daniel" mark.

done.

After this, Jacques Daniel was injected into the barrel at the headquarters, and after being aged over the years in the barrel, it is delivered to people who love Jack Daniel, such as shops and individuals That's why.

Related Posts:

in Video, Posted by darkhorse_log