The era of "Downloading without buying clothes and printing with 3D printers" is a reality

Chanel isProduce clothes with materials output by 3D printersOr based on applied kinematicsClothes output by 3D printerClothing making using 3D printers is being done, but as 3D printing technology advances, "The future that everyone downloads and prints fashionable clothes at home" rather than going to buy clothes " It is gradually approaching.

Forget shopping. Soon you'll download your new clothes - Danit Peleg - YouTube

When designer Danit Peleg goes on a trip for several weeks, it is traveling around various places with only one suitcase, but at some point special clothes are needed to participate in important events It is said that.

Peleg who did not put formal costumes in the suitcase, but fortunately the event was a technology conference so it was possible to use the 3D printer freely at the venue. So Peleg hurriedly designed a skirt with a PC, read data with a 3D printer and output the parts all night. The next morning, the output pieces were combined in the hotel room, and the first skirt was completed.

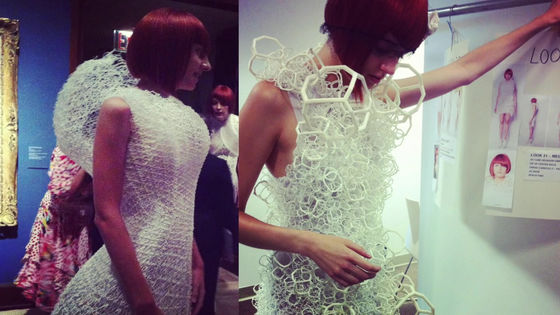

The skirt that Peleg is wearing in the following photograph was actually made with a 3D printer.

The back style is such a feeling, it is a natural finish that I can not imagine having made it with a 3D printer unless told.

It is not the first time for Peleg to produce clothes with a 3D printer, but he seems to have made clothes with a 3D printer even when he was a student at a fashion design school. However, at the time there was no detailed knowledge of 3D printing technology, making 5 clothes in a production period of only nine months was a difficult task. The illustration below is a design draft of clothes painted by Peleg during my school days.

Peleg likes to bring a large machine to the house and make clothes, he seems to have tried new materials every day and made original textiles.

Peleg also said, "Because he also liked collecting unusual materials in old factories and clothing shops, huge machines and strange materials occupied living at home, and roommates were annoyed." I will review.

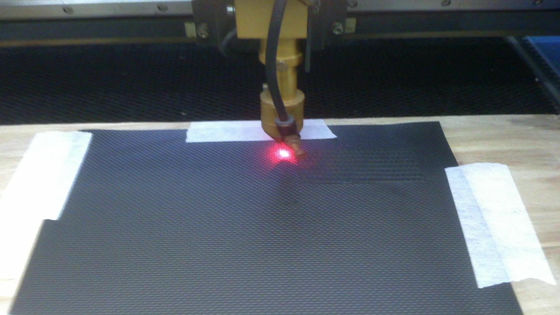

So, Mr. Peleg moved the workshop and decided to collect various machines such as knitting machines, laser cutters, silk screen, etc., and to produce clothes. The following machines are huge knitting machines that can not be placed at home.

This is a laser cutter.

Peleg, who began his internship at a clothing store in New York's Chinatown during the summer vacation, tailored 2 dresses using 3D printers.

However, at the time I used hard plastic for the material of the clothes, it had the drawback of being very fragile.

Furthermore, he seems to have had the problem that it is impossible to sit on a chair with his clothes on, or scratches are made if plastic scallops hit the skin. If you use a 3D printer for clothing production, there is a big merit of being able to output the shape of the clothes the designer is imagining as it is, but since 3D printers themselves are expensive and huge, it is difficult to design costs and places of storage It also had disadvantages.

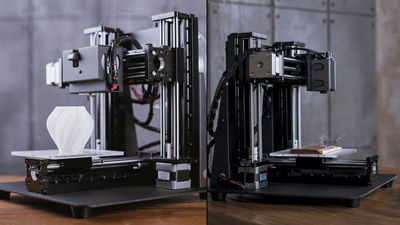

Peleg who finished the intern got to know the existence of a 3D printer for home use that is cheaper and easier to use than the business 3D printer used for clothing production at intern interns, "If you can make clothes using a 3D printer at home It seems he came up with "?

In order to realize the idea of making clothes designed by myself without going to a store, Peleg will begin learning more about 3D printing technology looking for a small workspace.

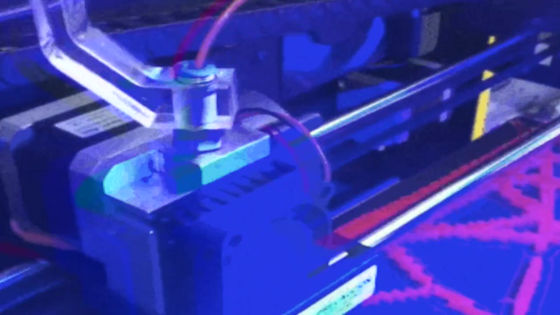

Then, Peleg who began using 3D printers started looking for filaments for 3D printers that are suitable for clothing material. Since it was known that the PLA material was hard and easily caught on the skin and easily broken,FilaflexPeleg noticed that the outputted parts were very strong and flexible, suitable for clothing materials, when I tried the new material.

Filaflex is a very soft material which does not break even if it grasps with the force as follows.

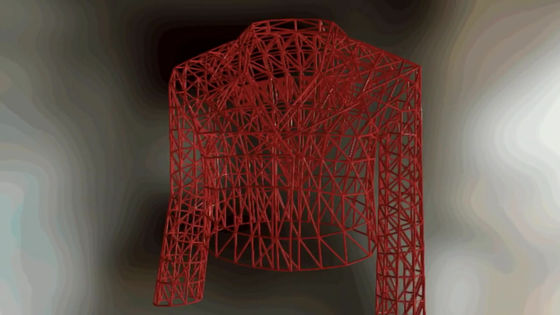

Using this Filaflex, Peleg produced a red jacket. Everyone in this jacket dataDownloadableSo, it is now possible to make the same jacket with a home 3D printer.

The state of being worn is as follows.

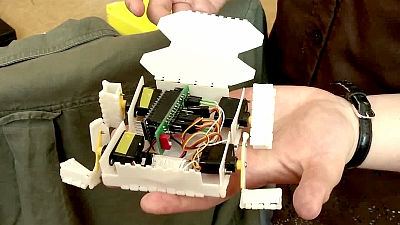

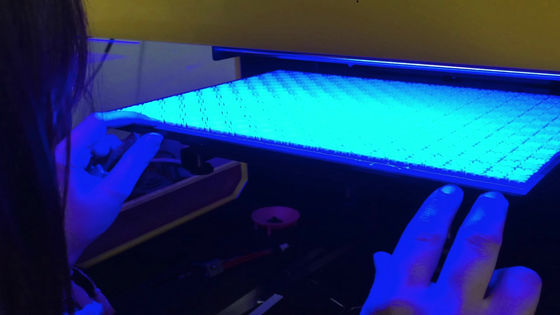

However, the parts that can be output with home 3D printers are very small, so we need to combine many parts like puzzles.

The situation during assembly is as follows.

Furthermore, Peleg decided to aim to make patterned clothes in the same way as general clothing. It searched open source for clothing patterns and succeeded in producing beautiful fabric that can be used just like ordinary cloth by outputting parts with 3D printer.

Succeeded to make lace-like thinness and stripe pattern cloth, depending on the color of the parts and how it is combined.

The skirt with this lace-like cloth lifts the hem ......

When dropping with Poton, I have a considerable elasticity that it hits the ground and bounces like a spring like a spring.

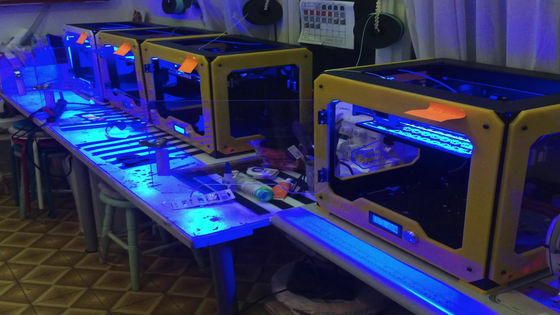

Peleg seems that it took a total of 1500 hours (about 62 days) to actually move 6 home 3D printers for 24 hours in order to produce 5 clothes with a 3D printer.

The following five clothes are the clothes actually made by Peleg.

The appearance that the model woman is actually wearing is as follows.

Roughly large mesh pattern is characteristic.

Shoes were also output by Peleg at home using 3D printers.

Viewed from the side.

If the technology of the 3D printer improves further, it will be possible to output clothes in a shorter time and it will be possible to make T-shirts that fit your shape in just 2 to 3 hours at home, Peleg I'm predicting. In addition, materials for 3D printers also evolved, it would be possible to make cloths with looks and textures like cotton and silk.

Peleg says that the era of clothing will "download trendy designs at home" as it changed to the way music is bought by download rather than record shop.

Related Posts: