When you produce baseball bats with DIY, this movie

DIY enthusiast Darbin Orvar has published a movie that summarizes how to make homemade baseball bats from wood screening to cutting and finishing wax processing on YouTube.

Darbin Orvar: Baseball Bat from Rough Sawn Lumber - YouTube

Darbin Orvar is getting into DIY so much that he has a room for DIY at home. This time it is based on baseball bats made in 1950s, making original bat.

Normally, I use strong wood such as Tonelico and Hickory as the material of the bat, but Orvar decided to use maple material and walnut (walnut) material with emphasis on strength and appearance.

So, we prepared 2 maple materials and 1 walnut material.

Put the bat on the wood ......

Check the part suitable for the bat and mark with chalk.

Mark each of the three woods to be about 40 inches (about 100 cm) in length.

Cut the wood at the marked part.

The width of the prepared walnut material was wider, so cut the side and make the width equal.

Next, we will flatten the surface of the wood using a hand-made electric cannula.

This machine is a commercially available electric cannula which is upside down and fixed to a table, and it seems that work of smoothing the surface of wood is much easier than before.

Next, adjust the thickness of the wood through the wood through a machine that makes the thickness uniform.

Next is the work of laminating wood. Bring the three processed plates to the DIY room and spread the wax sheet on the workbench so that glue does not spill.

I spread the glue with the roller on the surface of the wood.

A coloring paper

Paste the three plates perfectly.

Fix the wood to each other using a clamp.

Leave it as it is for half a day until glue firmly sticks.

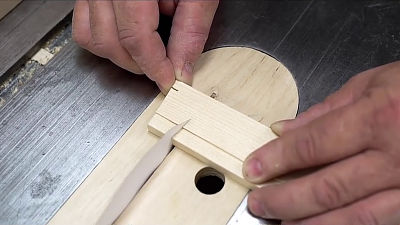

When the three plates are properly attached, scrape it so that the side becomes smooth and process it.

Put the bat on the wood again and measure the size ......

Cut both ends and decide the length.

Cut the extra part of the side, and work so that the top surface becomes a square.

Draw a circle using a ruler and a compass ... ....

Processing is easy to cut by dropping the four corners.

The state where the horn is dropped is like this. At this point the weight of the wood is about 2.8 kg.

Next we pierced the center of the wood's top surface ... ...

Set on machine.

When turning on the switch, the wood turns and starts to turn.

First of all, we will sharpen the surroundings uniformly so that the wood is cylindrical. Even though it seems to be a beautiful cylindrical shape while cutting it, it is often time consuming work that corners are left when stopping rotation.

Once molded to a certain extent, measure the diameter of the original bat ......

Decide the diameter of the handle side.

I will scrape little by little from the handle part.

Occasionally, put the bat on the wood and measure the diameter ......

Repeat the task of attaching a mark and shaving it until it gets a moderate thickness.

At the beginning of scraping, the surface has a step and it is decorated.

As I continued my work, I gradually turned to look like a bat.

It was said that the balance of the hand was very difficult to balance.

Finish using three types of file to smoothly process the surface.

If you press the paper against the center of the bat and rub it ... ....

Original stamp has been transferred.

To complement the color of wood, Orvar made her own work at DIYwaxIt fills the whole bat.

Coloring the wax while rotating the bat

Finally, cut both ends of the bat that was fixed to the machine ... ...

Remove the bat from the machine. Looking at the finish of the homemade bat, Orvar looks quite satisfying.

In addition, make a metal plate with initials ... ...

Apply glue to the handle portion of the bat.

Fix the metal plate with a luggage, complete.

That's why the finished bat is about 86 cm in length and about 900 g in weight and somewhat heavier.

Walnut's dark brown is characterized by an accented striped design.

The handle part is like this.

There is a stamp near the head.

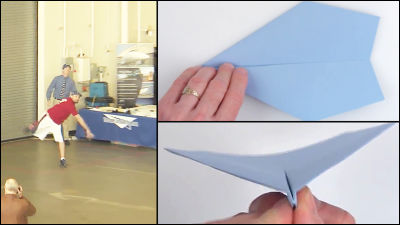

In fact when Orvar tried using the bat, it succeeded to hit the ball firmly.

In addition, wooden bat for professional baseball has one using laminated wood and one made by scraping a piece of solid wood, and in the following movie you can see the state of bat making using solid wood material.

THE MAKING (67) Until a bat is made - YouTube

Related Posts:

in Video, Posted by darkhorse_log