Movie of cello craftsmen who put the process of making stringed instrument "cello" from wood shavings to string tension

A string instrument "Cello" which is larger than the violin and slightly smaller than the contrabass is a musical instrument with four strings and bass echoes. A cello craftworker cut out timber, assembled several parts and chased the state until one cello was completed "La construccion de un violonchelo"Is on sale.

La construccion de un violonchelo, Building a Cello ("Els Secrets de la Casa del So") - YouTube

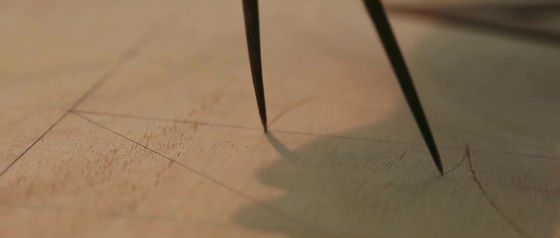

First of all, we will make "inner mold" that supports the interior of cello. Pull a line with a pencil using a ruler or a triangle ruler ......

I use the compass for the curve part.

Place a transparent plastic mold and draw the contour symmetrically.

Then apply adhesive on the square material ...

Use a brush to spread the woodworking adhesive on the surface of the square.

Bonded a square material between two cut inner cutters.

It clamps securely with a clamp.

Xavier Vidal of string instrument craftsman says, "Our work is a profession that requires advanced knowledge and instinctive sensibility about instruments to repair and produce string instruments."

Confirm by touching the side of the inner mold that you pasted.

I will scrape the surface so that it becomes smooth.

First of all, I'd like to use flat "only" to crunch the surface of the wood.

Next, change to a file with fine eyes and prepare the mold.

Paint glue with a brush on the notch on the side ... ...

Fit the block material on the side to increase the strength.

Fix the block material with a clamp.

Measure the width of the block material with the measure.

Using a round "only" and a hammer will cut off unnecessary parts.

Ramon Andres of the essayist answers "If the musical instrument producer is" a craftsman "or" an artist ", he answers" a craftworkman with a high expression power. "The concept of" artist "is satisfied with the craftsman class It is a new way of thinking that people in the 18th century did not want to distinguish their profession as "craftsman." I do not think that instrument instructors are inferior to artists.Amatee clanYaAntonio Stradivari,Guarneri clanYou can say it is a craftsman with the best knowledge. "

Next, cut the thin plate to be adhered to the side with canna so that the thickness becomes uniform.

I will bend the wooden board with a bending iron.

Adjust the degree of bending with steel plate.

Paste the plate on the side of the inner mold.

When it is too long cut saw unnecessary part.

Glue the glue ......

Secure with clamp.

Cellist, Lito Iglesias says, "We are musicians and cello players.I know a little about how to make musical instruments, but instrumentalists should know more about the process of making instruments more. If you know the structure of a musical instrument it will be very useful for playing.If you know the secrets of the structure and shape of the instrument, you will be able to produce the best sound. "

Cut finely the block material fitted in the inner mold according to the degree of curvature of the side plate.

Further, bending the thin plate while heating ......

Reinforcement stuck on the inside of the side plate.

Crimp with a large amount of clamp.

From here we make cello's front board. First of all, we pasted two boards together.

Place the inner mold on the plate, trace the inner mold with a pencil and copy the mold to the plate.

Use a sharp pointed object like a dragon to trace the outline.

Cut out the faceplate with a thread saw along the contour line.

Cut the fine part of the curve by hand.

Next is work called "arching" that makes cello surface round. Roughly scraping the surface with only a round ...

Small irregularities are trimmed with a small canna.

Finally, use a spatula tool called scraper to finish the surface smoothly.

According to Eduart Bosque, a cello craftworker, the most creative step in making a cello is to create an inner mold. In recent years, however, inspiration for musical instruments called masterpieces of the past often inspired us to make inner shapes, and it seems that the process of making molds that really requires creative skill is becoming less shadowy.

When the top board is completed, I will dig a groove all around the outer edge along the border.

Pour glue with a syringe into the groove and fit the perfringing material.

Hit the hammer from above to embed the perfrinding material.

Finally scrape the surface only with a smooth finish to complete the perfringing. Perfringing not only serves as a decoration of cello surface, it also has the effect of preventing cracks and cracks in wood.

Adjust so that the thickness of the front plate is constant.

Next time I will scrape the back of the board.

Shaving the whole with only a round ... ...

I arrange the irregularities with a small canna.

Cello craftsman Xaviel says, "The process of making a cello is full of secret technologies that only cello craftsmen know, but at the end it is always mysterious how the cello finishes and what kind of tone it plays I am talking about the fun of cello making.

The work of emptying the f-character peculiar to stringed instruments begins with taking the shape of the hole on the surface of the plate first.

Adjust finely so that the distance from the center becomes symmetrical.

Leave a hole ......

Cut out the f-hole with thread.

I will cut the details with a knife.

I arrange around the hole with a scraper.

A cellist, Lito says, "When playing a cello, the quality of the sound depends on the quality of the instrument.The player's technique evolves by using superior instruments," said the cello player, I am committed to you.

Work on attaching a skeleton called "bus bar" inside the top board. Adjust the size of the square ... ...

Fix it in the center of the front plate.

Use only the extra block material to cut.

Paste the side plate and the front plate with glue.

Cello craftsman Eduart says, "When we assemble instruments, we constantly think about players and are challenging to make instruments that are suitable for professional musicians and people who are studying music. As a craftworker of myself It is also important to polish your arms, but I would like the players to feel the function and beauty of the instruments. "

When the main part of cello is finished, it cuts out parts called "neck" from the square material and makes it.

It seems that all characteristic spiral patterns are made by hand.

We will flee the part that stores the string with fleas.

Fit the completed neck into the body of cello.

Fit the joint only with it.

Essayist Ramon says that stringed instruments have remained unchanged since long ago and have been using "mature period" as an instrument for a long time. For this reason, "stringed instruments are said to be more complete than other musical instruments and electronic equipments".

Next, before painting the surface, we will polish the whole.

We carefully spend a lot of time carving fine pieces.

First of all paint the base with alcohol.

We measure the powder that is the source of varnish ... ...

Mix with solvent.

After powdering with solvent, put a varnish on a spatula ......

I will paint on the surface of the cello.

In addition, create a dense varnish.

I paint varnish twice.

I paint the varnish with a brush on the neck part.

Finally it is completed by polishing the whole with a cloth containing oil.

Cello player Lito says, "Unlike players cello craftsmen will not go up to the stage of the concert venue, only their work will appear on the stage.The work of cello craftworkers is not so famous, so the craftsmen You may feel that it is not accepted internationally. "

The neck portion where strings are stretched scrapes the surface to make it hard to slip when you hold it.

Glue the glue ......

Crimp the finger board with the clamp fixed.

Make a hole for the peg at the top of the neck.

In addition, on the bottom of the fuselage, make a hole for the end pin to stand the cello on the floor.

Insert the end pin parts.

Insert thin cylindrical wood into the cello from the f-hole.

This wood is a part called "soul pillar", and it has a role to make the sound resonate well by connecting the front and back plate of the cello.

The piece that hits the string adjusts the thickness according to one cello.

Fix the piece in the middle of the f-hole.

Dig into a groove that hangs the string at the top of the finger board.

Also hook strings on the pieces, fixing a total of 4 strings.

Finally, ring the tuning fork (...)

Tuned the cello tone.

That is why the cello finished is sold at the musical instrument store.

Related Posts:

in Video, Posted by darkhorse_log