Just made with artistic delicacy Japan's world-class "sake" manufacturing site

In recent years, "sake" has been highly regarded overseas, "sake (SAKE)" attracts a great deal of Japanese traditional food following sushi (SUSI), such as sake bars gaining popularity in the US · New York and France · Paris It is being done. Japanese sake brewing that embodies such Japanese tradition has been inherited from time to timeTakeshi (Tojo)Our craftsmanship technique and a hybrid manufacturing site with modern equipment has become.

SHUHARI

http://sawayamatsumoto.com/

Sake brewery in Kyoto "Sawaya MatsumotoFrom the documentary movie that recorded the brewery of Japanese sake, you can see the process of Japanese sake brewing that reached the arts area.

Brewed in Kyoto with Shuhari Spirit - Vimeo -

Morning of Kyoto.

A large roof where the tiles are arranged in order.

The old-fashioned key.

The door was opened.

Craftsmen come all the way into the building.

The light is lit and the work is finally started.

In Japanese sake brewing, "water" is important. Good water such as groundwater and underwater water is essential for Nippon sake brewing, and water for preparation itself is sometimes sold from the brewery.

And it goes without saying that "rice" is life.

Rice to be used is "five hundred thousand stone" from Nanto. The quality will be carefully checked.

Smooth.

The first step is "rice wash". Rice like jewels transferred to the mackerel ... ...

Rinse it like cleansing with clear water.

Rice washing is manual work by craftsmen.

According to Mr. Sawaya Matsumoto of Kuramoto, "Rice washing is the second milled rice".

"Jewelry" will be further refined.

The shaved rice will be transferred.

A craftworker who knocks the back of Zaru like a drum.

Collect all the jewels.

Measure the time with a stopwatch.

Time management is very important in sake brewing. Each process is thoroughly time-managed.

I am putting hot water in a barrel.

Sterilization treatment in progress.

All cases etc are also sterilized with boiling water.

Sake made by fermenting koji which is one type of mold with yeast seems to require thorough hygiene control also in containers used for manufacturing.

Sharpened rice is packed in a bag and moved to another process place.

The boiling water boiling water.

The next step is "steamed rice". Steam covers the building.

Conditions for making good sake are "1, steamed 2, steamed 3, made." Sawaya Matsumoto said that it focused on rice processing.

It is impossible to think that it is the 21st century.

A ridiculously long gable roof covered with roof tiles ... ...

chimney. It is a hybrid of traditional equipment and modern equipment.

A schedule chart that was elaborately calculated.

Fine time will be written on the whiteboard.

The craftsmen started busily preparing.

Adjust the pressure.

Steamed rice is completed.

I will be briefly taken to the next process location.

When unwinding white cloth, white rice which steamed up appears.

Work in large numbers. Finally "Koji making" of the most important step in Japanese sake brewing.

I will heat it with a fan and lower the temperature.

Spread it on a big desk ......

Mix.

In order to check the condition of koji, I will put a thermometer.

Shimme more.

And sprinkle with Aspergillus oryzae.

Depending on the situation such as temperature and humidity the amount of koji mold is different, it is impossible to mechanize. It is a showroom of Mr. Take's arm that carries everything with Koji and it is exactly a crafter's art.

Mixed rice koji is high ......

It is wrapped in cloth.

Cut it out with such a pestle ... ...

Please make it small ...

To a smooth condition.

I carefully prepare the surface with trees.

Next is to "ferment" rice to ferment

Add liquor and yeast to steamed rice to make a liquor mother.

Fermentation conditions are of course managed by craftsmen.

Check carefully with stirring with a special instrument called a paddle (Kai).

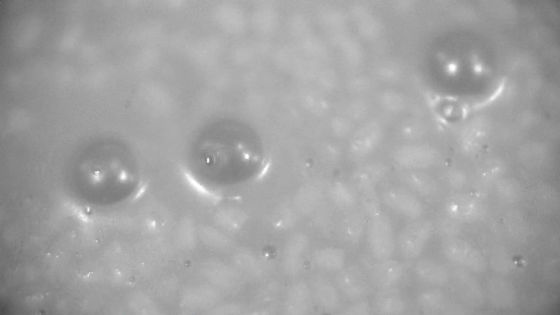

As yeast grows, bubbles come up from mushrooms (mushrooms).

Sake made by fermenting with rice washing · koji · yeast is a completely different wine making method from wine which is made by fermenting grapes. In a rough way of speaking, unlike wine which can be done by leaving the fruit in a barrel, the degree of sophistication of sake making is another dimension, as it is necessary to make koji in sake. You can see tradition and depth as a breath.

Change gradually and clearly.

Sake will be born if you narrow down the fermented wine.

In a well-organized brewery.

Finally bottling of sake.

One bottle juxtaposed tightly.

Bottling work is mechanized.

Translucent sake.

It can be attached automatically to the lid.

Put it in a case ......

Lift with a forklift ......

Moved between the tank and Swiss.

Finally washed.

One bottle is carefully wiped ... ...

The labels are stuck manually.

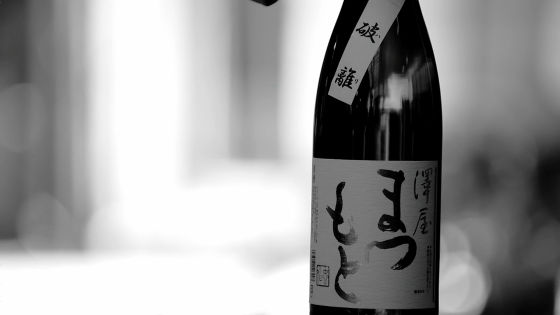

What was completed in this way ......

Pure rice raw sake "Safety breaking apart" by Sawaya Matsumoto.

The manufacturing process of sake made by "master's skill" by traditional craftsmen is delicately influenced by the season, the quality of rice and water, etc., so it seems as if to make one handmade artwork of one item one item is.

Furthermore, pure raw rice liquor "Mamoru Isolation" of Matsumoto Sawaya is on sale at 2366 yen (tax included) at Amazon.

Amazon.co.jp: Sawaya Matsumoto defensive breaking sake rice 1800 ml: Food / Beverage / Liquor Mail order

Related Posts: