Birth of surface processing technology that laser treatment of metal surface thoroughly repels water

Many water repellent processes that repel water will coat the surface of the material and the effect will be reduced if the coating is peeled off. On the other hand, researchers at the University of Rochester made a laser treatment on the metal surface to "do not fall off" water repellent technology "Super-hydrophobicSucceeded in the development of.

Using Lasers to Create Super-hydrophobic Materials - YouTube

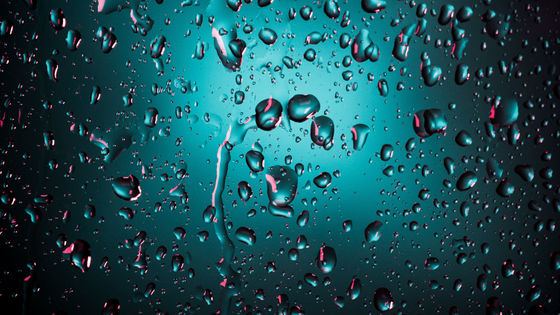

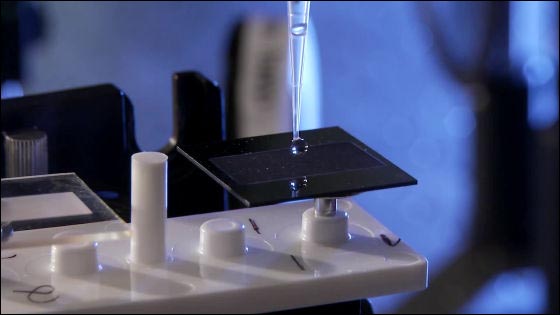

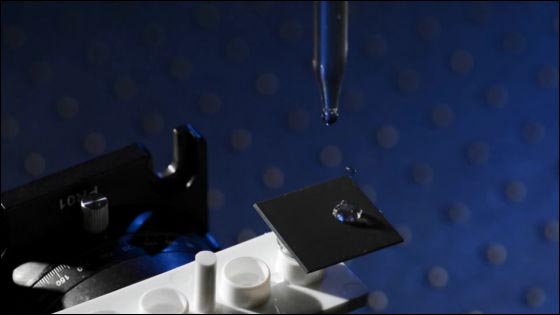

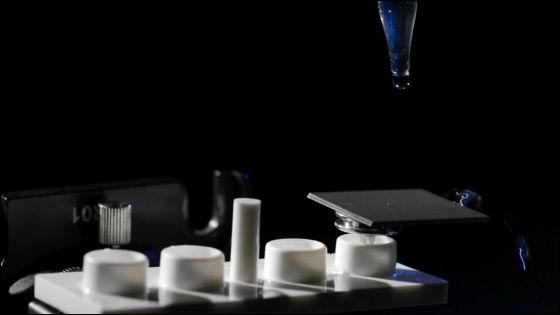

When dropping water droplets on the metal surface with a dropper ......

As soon as the water droplet contacted the surface, it spread to the metal surface in a moment. This is an example in which the penetrability of water is enhanced by a technique of processing a metal surface with "Super-hydrophilic" laser pulse.

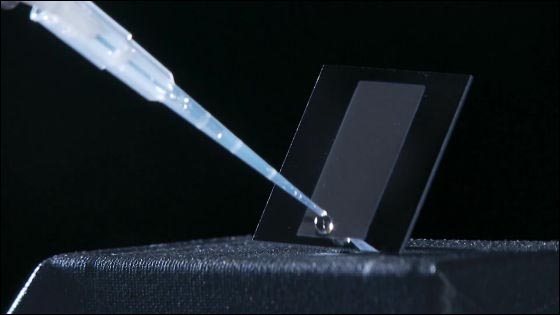

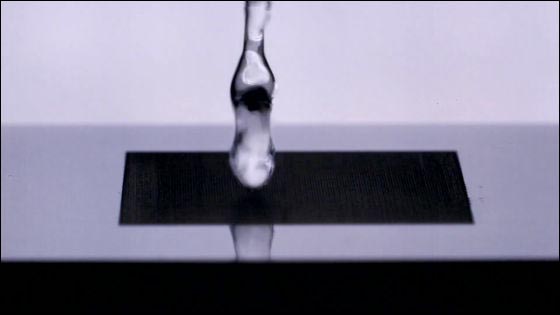

Water drops touching the metal surface ...

It will also spread upward as if resisting gravity.

By utilizing Super-hydrophilic it is possible to dramatically increase the hydrophilicity of the metal surface.

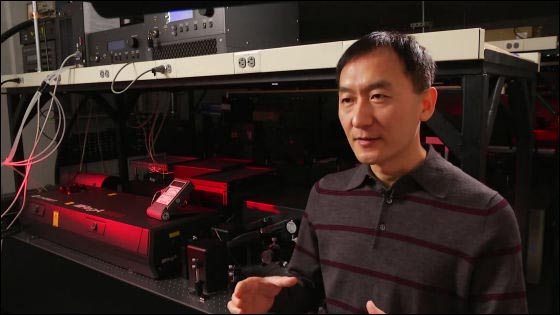

"We've been researching super hydrophilic technology to enhance hydrophilicity, but on the contrary, we have developed a technology" Super-hydrophobic "that enhances hydrophobicity (water repellency)," said Kuo of the University of Rochester Professor Chunlay.

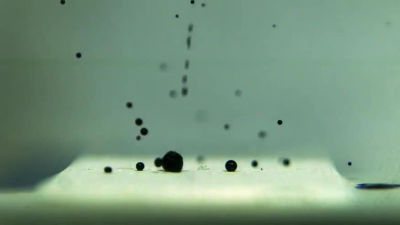

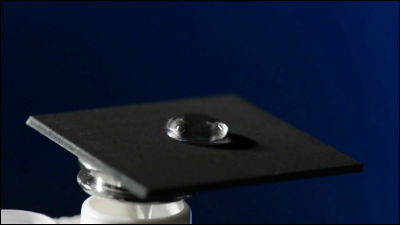

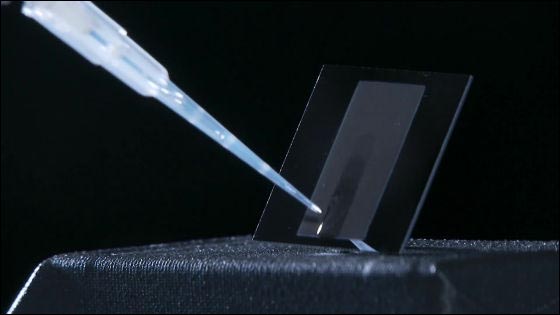

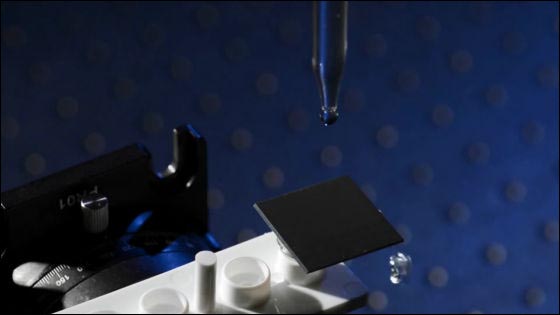

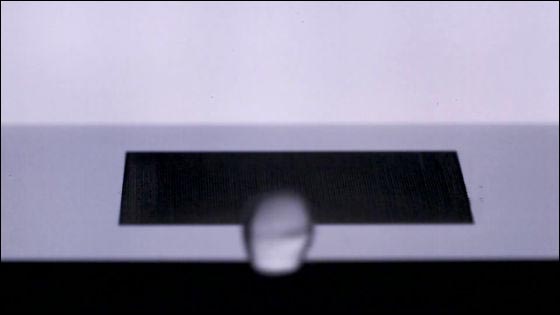

Again, water droplets are dropped onto the metal surface that improved water repellency.

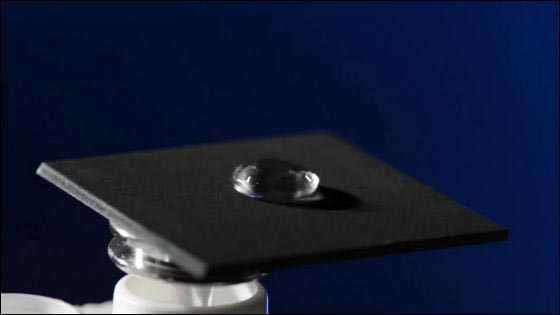

Then the water droplet was scooped back to the metal surface to slip down.

I will look at the details of how the water droplets were repelled by slow motion.

The droplet that dropped ......

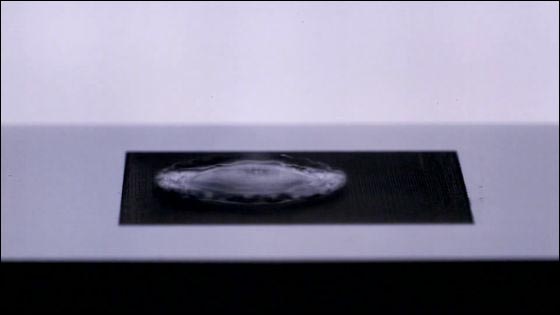

After feeling like flattening like this with shock ......

It gets clumped by the spread reaction and jumps vertically.

It was perfectly rejuvenated.

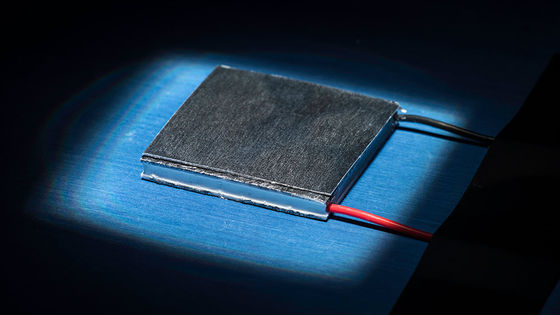

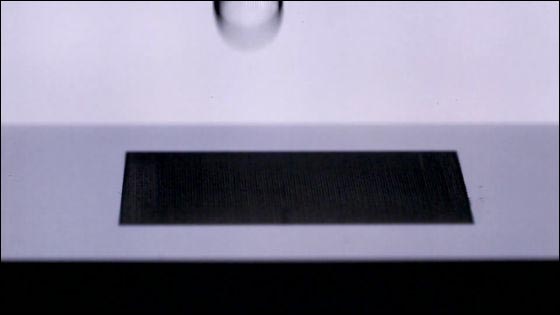

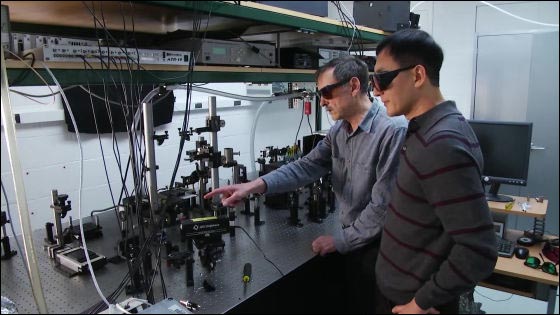

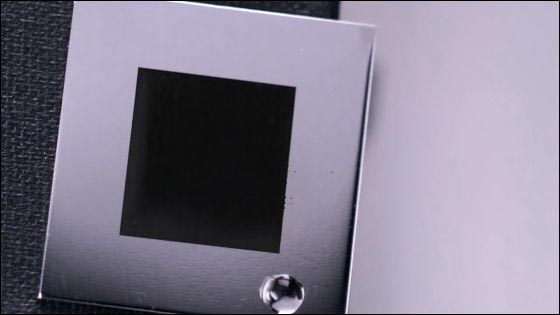

In Super-hydrophobic, the metal surface is processed with a femtosecond laser with a pulse width of several femtoseconds.

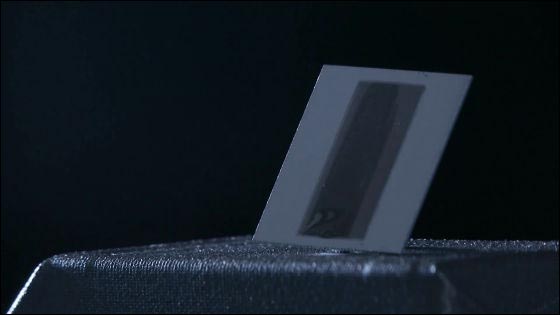

With water repellent finish with Super-hydrophobic, only a slight angle is attached to the metal ......

Water droplets slide down as if the balls are rolling.

"Super-hydrophobic can be used for various industrial products"

General water-repellent processing technology is a coating so there is a risk of peeling off.

Typical is teflon processing of frying pan.

Teflon processing which is said to have high water repellency, but there is no water repellency as much as Super-hydrophobic processing.

Teflon processed frying pan should be tilted about 70 degrees and water droplets attached to the surface will not flow down.

Also, water droplets flow only slowly.

On the other hand, Super - hydrophobic will slide down watching if there is only a slight angle.

Every droplet that falls will be repelled.

"Super-hydrophobic is a technology ahead of the coating, has much higher water repellency than coating processing, and there is no worry of peeling off"

Super-hydrophobic seems to be useful in a wide range of fields. For example, if Super - hydrophobic processing is applied to roofs and wall materials, durability of the house can be enhanced while preventing rain stains. In addition, Dr. Ku said that clean water is very valuable in developing countries, so using Super - hydrophobic technology saves rain water without penetrating into the soil, reduces the amount of water flowing in the toilet, valuable We will say that you can use water without waste.

In addition, we can learn more about the research contents of super-hydrophobic surface processing technology that realizes super water repellency in the following papers.

Multifunctional surfaces produced by femtosecond laser pulses

http://scitation.aip.org/content/aip/journal/jap/117/3/10.1063/1.4905616

Related Posts: