LG develops material that is 1/100th the thickness of a human hair and can reduce the risk of lithium-ion battery explosions

Thermal runaway prevention through scalable fabrication of safety reinforced layer in practical Li-ion batteries | Nature Communications

https://www.nature.com/articles/s41467-024-52766-9

100x thinner-than-hair material cuts EV battery explosion risk by 50%

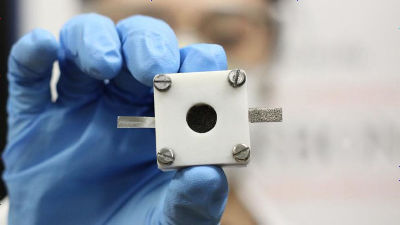

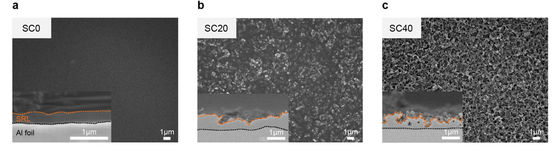

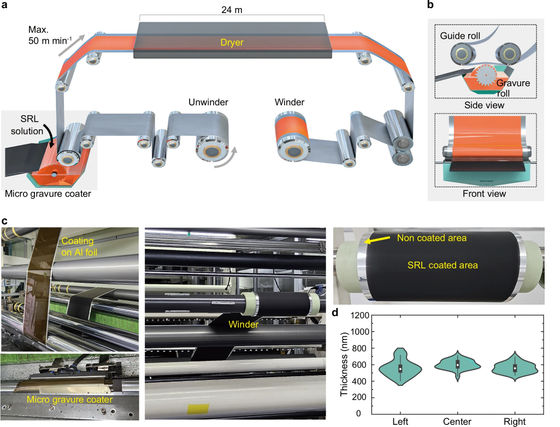

The new material developed by LG Chem, called the 'Safety Reinforced Layer' (SRL), is just one micrometer thick - one-hundredth the thickness of a human hair - and is placed between the cathode and current collector of a lithium-ion battery.

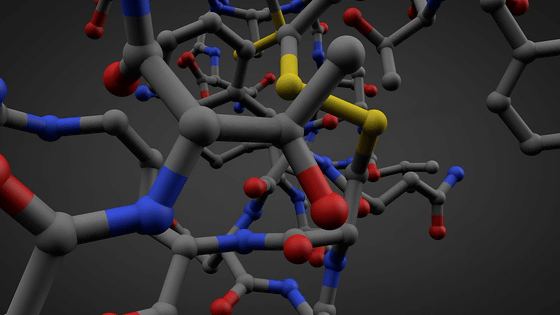

SRLs act as fuses in lithium-ion batteries. At normal operating temperatures, electricity can flow freely, but if the battery temperature rises beyond a safe range, the SRLs react. 'When the battery temperature rises beyond the normal range of 90°C to 130°C, the SRLs react to heat and change their molecular structure, effectively inhibiting the flow of electrical current,' explained the LG Chem research team. This helps to prevent dangerous thermal runaway that can lead to fires or explosions in lithium-ion batteries.

In addition, the SRL can quickly respond to any temperature change, and the research team said, 'For every 1 °C increase in temperature, the electrical resistance increases by 5000 Ω. The maximum resistance of this material is more than 1000 times that at room temperature. ' Also, when the temperature drops, the SRL will return to its original resistance value, and the battery will function normally.

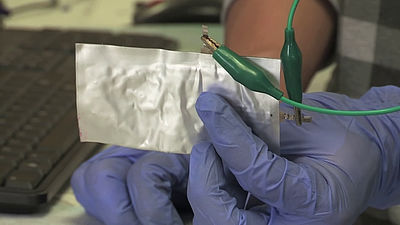

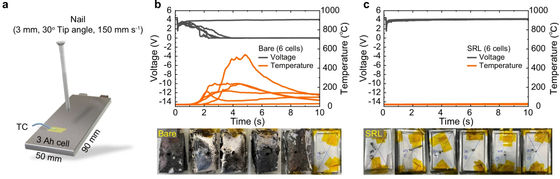

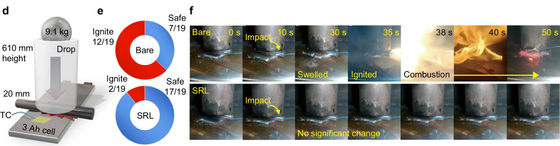

To demonstrate the effectiveness of the SRL, LG conducted tests in which it hammered nails into

The research team then conducted an experiment in which they dropped a weight of about 10 kg onto a nickel-cobalt-manganese battery for electric vehicles. When the weight was dropped onto a standard battery, all of the batteries caught fire, but only 30% of the batteries equipped with SRLs caught fire. It was also reported that in the 30% of batteries that caught fire, the fire was contained within a short period of time.

According to LG Chem, the SRL can be easily integrated into existing lithium-ion battery mass production processes, and the research team has already conducted demonstration experiments for mass production of the SRL. 'The SRL has produced experimental results that make it suitable for mass production in a short period of time,' said Lee Jong-Ku, Chief Technology Officer of LG Chem. 'We plan to strengthen our safety technology so that customers can use electric vehicles with confidence, and contribute to strengthening our competitiveness in the battery market.'

Related Posts:

in Science, Posted by log1r_ut