AI-designed, 3D-printed rocket engine successfully undergoes firing test

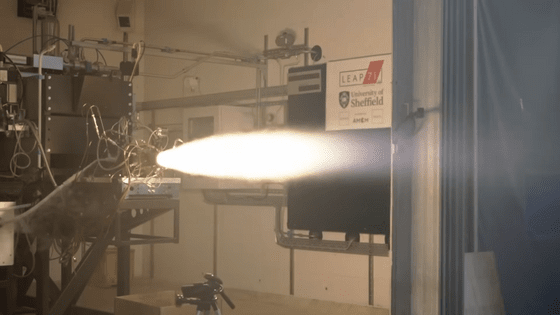

Dubai-based AI engineering company LEAP 71 has announced the successful firing of a liquid-fuel rocket engine designed by Noyron , a large-scale computational engineering model, and 3D-printed.

LEAP 71 hot-fires 3D-printed liquid-fuel rocket engine designed through Noyron Computational Model | LEAP 71

https://leap71.com/2024/06/18/leap-71-hot-fires-3d-printed-liquid-fuel-rocket-engine-designed-through-noyron-computational-model/

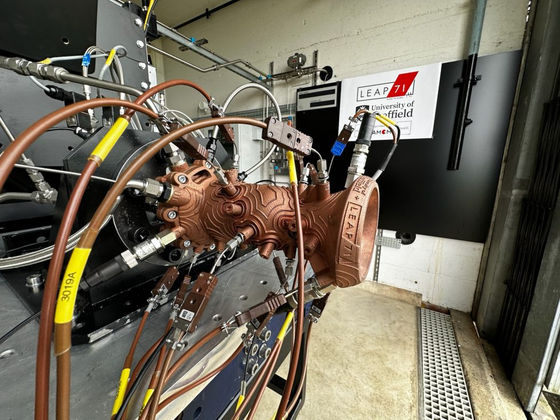

LEAP 71's goal has always been to fundamentally advance engineering through the emerging field of computational engineering . As part of this, LEAP 71 is developing Noyron, a large-scale computational engineering model that learns the rules of physics and manufacturing processes, including thermal models, as well as related data and expert knowledge, to predict physical interactions, including mechanical motion, thermal behavior, and other performance parameters, to design machinery.

Based on the data designed by Noyron, LEAP 71 worked with AMCM , a major German metal 3D printing company, to manufacture copper thrusters using the EOS M 290. According to LEAP 71, it took Noyron just 15 minutes to generate the thruster design, and the process from deciding on the final specifications to manufacturing was completed in just under two weeks.

The thrusters developed this time are similar to those used in the final kick stages of relatively compact orbital rockets, with a thrust of about 5 kN, and are fueled by

The thrusters are also equipped with multiple ports for measuring temperature and pressure, allowing Noyron to learn from experiments.

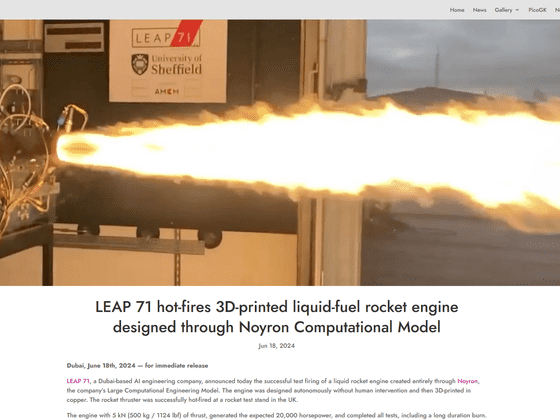

The combustion test took place at Airborne Engineering 's test site in Westcott, UK on 14 June 2024. After a 3.5 second preliminary test, a 12 second long burn test was carried out.

The engine performed as expected and achieved steady state operation, after which it was disassembled and carefully inspected at the University of Sheffield, where it was confirmed that no damage had occurred during the firing tests.

'We are at the forefront of a new field of computational engineering, where we can design advanced machines without human intervention, and this paradigm can dramatically accelerate the pace of innovation in real-world objects,' said Lynn Kaiser, co-founder of LEAP 71. 'The fact that we were able to successfully complete the combustion test proves that our approach works.'

Related Posts: