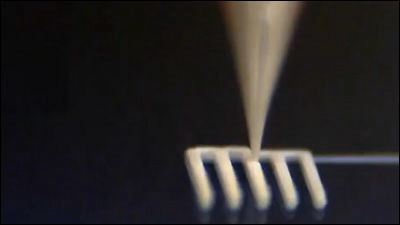

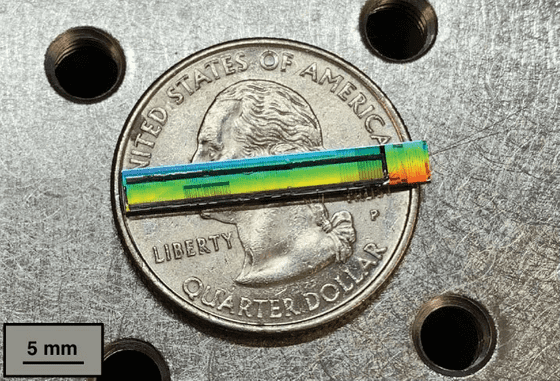

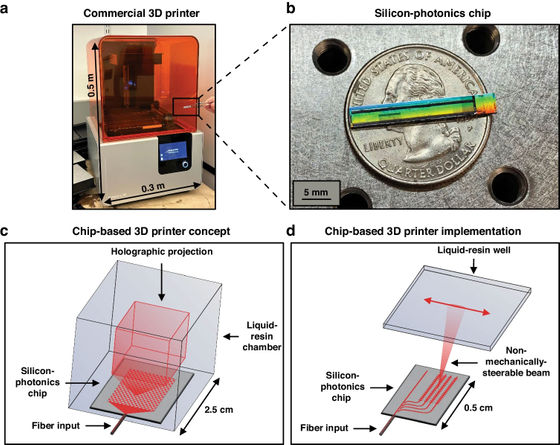

The world's smallest 3D printer, just the size of a 100 yen coin, has been developed, with hopes for applications in the medical field and elsewhere

A research team from the Massachusetts Institute of Technology and the University of Texas at Austin is developing a prototype of a tiny 3D printer that is roughly the same size as

Silicon-photonics-enabled chip-based 3D printer | Light: Science & Applications

https://www.nature.com/articles/s41377-024-01478-2

Researchers demonstrate the first chip-based 3D printer | MIT News | Massachusetts Institute of Technology

World's first chip-based 3D printer is smaller than a coin — benefits from having no moving parts | Tom's Hardware

https://www.tomshardware.com/3d-printing/worlds-first-chip-based-3d-printer-is-smaller-than-a-coin-benefits-from-having-no-moving-parts

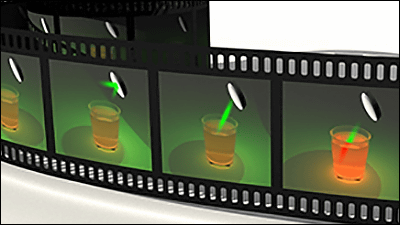

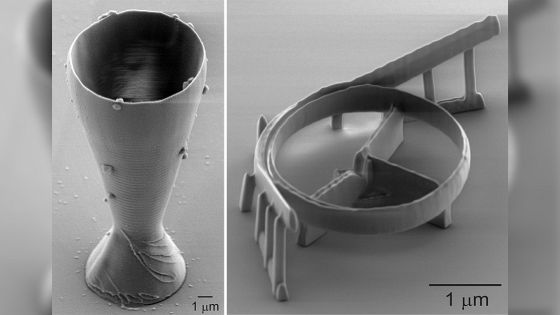

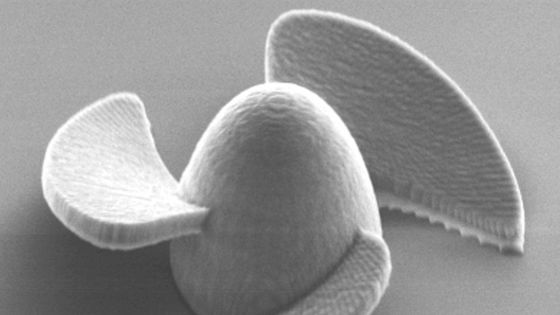

The tiny 3D printer developed by the research team is unique in that it has no moving parts and does not directly print parts, etc. What this 3D printer does is focus an irradiated laser into a liquid resin that hardens rapidly when hit by light of a specific wavelength.

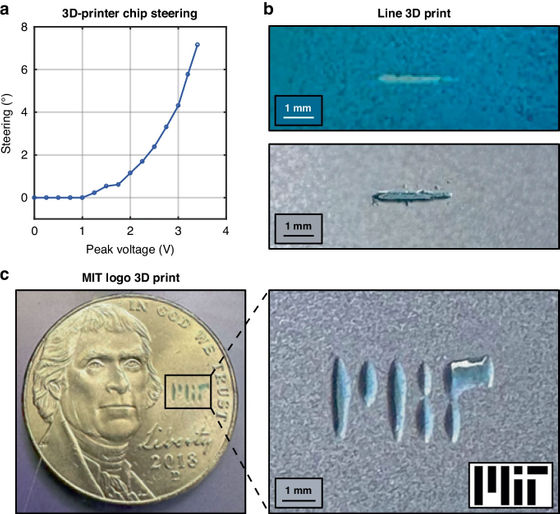

Instead of using arms and motors to change the focus of the beam, the 3D printer itself can move the focus of the beam to create the desired shape. In fact, the research team used the 3D printer they developed to create the Massachusetts Institute of Technology logo, 'MIT,' just a few millimeters in size. The printing took just a few seconds.

Sabrina Corsetti, a member of the research team, reported, 'Light-curing resins are difficult to cure at infrared wavelengths. Previously, tiny 3D printing has used integrated optical phased array systems for

'This system is a fundamental rethinking of what a 3D printer is,' said Yelena Notaros, a member of the research team. 'Instead of being a giant machine that you sit on in a lab chair and create objects, it's now something you can carry in one hand. It's exciting to think about the new applications that will emerge from this and how it will change the field of 3D printing in the future.'

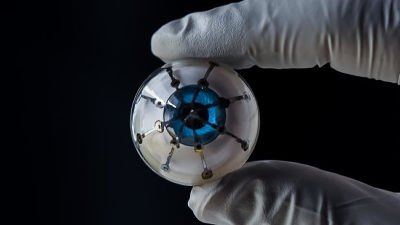

The research team speculated that the 3D printer developed this time could have a variety of uses, such as enabling clinicians to create custom medical device components or enabling engineers to create rapid prototypes in the field.

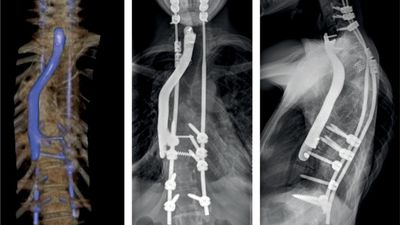

In addition, Tom's Hardware, an overseas media outlet, said, 'Orthopedic surgeons can use this 3D printer to create custom bone implants that help heal fractures based on the fracture status of the patient scanned by a 3D scanner.'

Moreover, if the team is successful in turning this concept into a viable product, anyone -- engineers, doctors, or even emergency personnel -- could create the solution on the spot, without having to carry around a traditional 3D printer.

The research team plans to develop a chip that will enable 3D printing in just one step by irradiating a 3D printer with a visible light hologram, and Notaros said, 'To achieve this, a completely new chip design is required. We will continue to work toward this ultimate demonstration.'

Related Posts: