Scientists and chocolate makers discover new way to make chocolate healthier and more sustainable

Cocoa, the raw material for chocolate, has been cultivated since around 2000 BC, and after it was brought to Europe by the Spanish in the 16th century, it became a luxury item. However, chocolate faces various challenges.

A research team from ETH Zurich has teamed up with a chocolate manufacturer to develop a 'healthier, more environmentally friendly chocolate.'

Valorization of cocoa pod side streams improves nutritional and sustainability aspects of chocolate | Nature Food

Scientists develop method of making healthier, more sustainable chocolate | Food | The Guardian

https://www.theguardian.com/environment/article/2024/jun/01/scientists-develop-method-of-making-healthier-more-sustainable-chocolate

The research team points out that chocolate has three challenges: nutritional, environmental and socio-economic.

Chocolate is generally known to be high in sugar and high in energy density. It also contains a lot of saturated fatty acids, which may increase the risk of obesity, type 2 diabetes, and cardiovascular disease. In addition, the cultivation of cocoa beans, the main ingredient of chocolate, requires a vast amount of land, which leads to the deforestation of tropical forests and contributes to global warming.

Furthermore, many cocoa beans are produced by small-scale farmers in developing countries, whose incomes are very limited. In countries that are highly dependent on the cocoa industry, fluctuations in the price of cocoa beans can have a significant socio-economic impact.

'The cocoa fruit is basically a pumpkin, and right now we just use the seeds, but there's a lot more that's great about this fruit,' said Kim Mishra, a food technologist at ETH Zurich and lead author of the study.

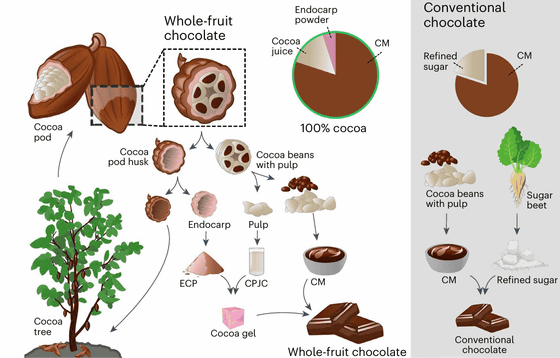

The 'pulp' around the cocoa bean and the 'endocarp', the inner part of the shell that surrounds the cocoa bean, are often discarded, so the research team developed a way to make chocolate using this pulp and endocarp in collaboration with chocolate maker Max Felchlin and Koa Switzerland .

The new chocolate manufacturing process is as follows: First, the cocoa pulp is extracted, the juice is extracted, and the juice is concentrated to obtain cocoa pulp juice concentrate (CPJC). Next, the endocarp of the cocoa is extracted, dried, and crushed to obtain endocarp powder (ECP). Next, the CPJC and EPC are mixed and heated to form a gel. This gel is a source of sweeteners and dietary fiber.

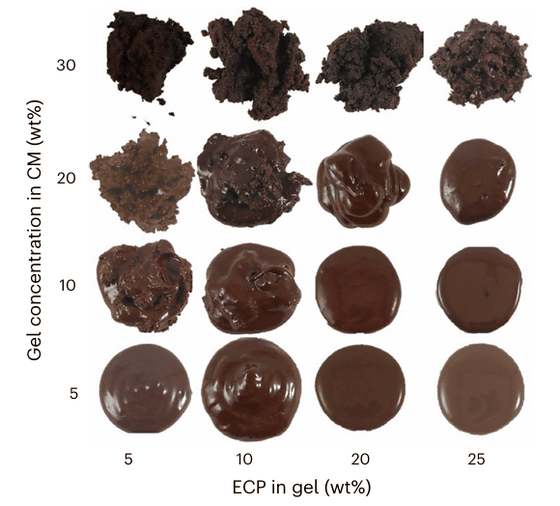

The cocoa beans are then fermented, dried, roasted and ground in the traditional way to obtain the cocoa mass, which is then mixed with the gel. In the study, the gel content was up to 20%. Finally, the cocoa mass and gel mixture is

The chocolate made using this method contains dietary fiber, and the natural sweeteners in the gel reduce the amount of sugar, making it more nutritious than regular chocolate and reducing the amount of saturated fatty acids. Of course, the results of the sensory evaluation showed that the chocolate made using the new method had the same sweetness as the conventional chocolate, the research team reported.

The new method uses the endocarp and pulp of the cacao fruit, which would otherwise be discarded, and therefore reduces the amount of cacao beans used, potentially reducing the amount of land needed to grow cacao and ultimately reducing the impact on global warming.

Furthermore, by creating commercial value for the waste endocarp and pulp, cocoa farmers will have the opportunity to earn an income, leading to diversification of their income sources. In addition, the research team claims that disseminating the technology to gelatinize the endocarp and pulp to farmers will also lead to improved technological capabilities in cocoa-producing regions.

Mishra commented, 'The texture of the new chocolate is basically the same as conventional dark chocolate, and the taste is similar to that of South American chocolate. The sweetness spreads in the mouth a little more slowly than with conventional chocolate, and you can feel the fruity aroma and acidity derived from the fruit juice more.'

Related Posts: