CubeFabs: Future modular chip manufacturing plants that use NVIDIA GPUs and AI to reduce size and cost

Industrial AI company

Nanotronics promises modular, shippable chip fab facilities powered by Nvidia GPUs and AI | Tom's Hardware

https://www.tomshardware.com/tech-industry/manufacturing/nanotronics-promises-modular-shippable-chip-fab-facilities-powered-by-nvidia-gpus-and-ai

In the age of automation and AI, the manufacturing industry has exploded with innovation. Nanotronics is proposing 'CubeFabs' as a new innovation in the manufacturing industry. Matthew Putman, founder and CEO of Nanotronics, said he hopes that CubeFabs will be used as a 'manufacturing model of the future.' The biggest feature of CubeFabs is that it is a modular power switch manufacturing unit bundled with AI software and hardware.

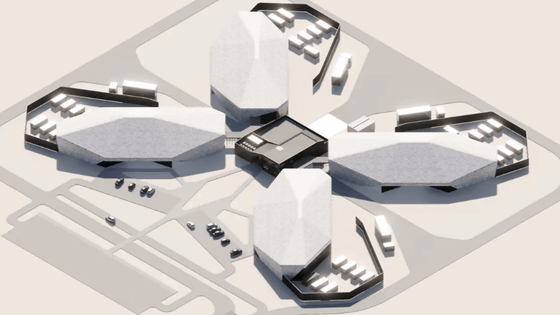

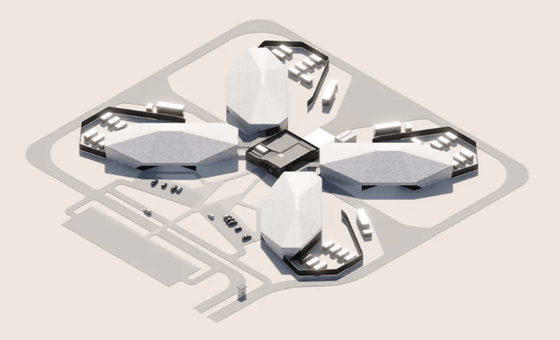

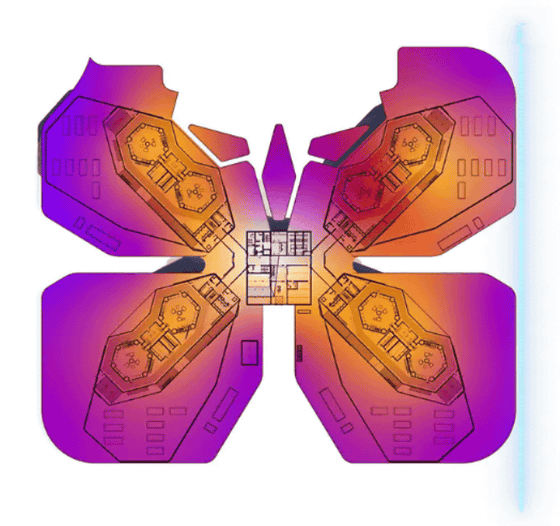

CubeFabs has a cube-shaped unit in the center, which is accompanied by four modular power switch manufacturing units. The minimum size of each modular power switch manufacturing unit is 1,715 square meters, and the minimum area of the entire CubeFabs is 7,510 square meters. According to Glenn O'Donnell, an analyst at market research firm Forrester, the power switches that can be manufactured by CubeFabs are used for power routing to data centers and inverters for electric vehicles.

The overall picture of CubeFabs is as follows.

The cube-shaped unit in the center of CubeFabs is equipped with an NVIDIA GPU to run AI software, which makes it possible to automate some engineering processes. Nanotronics has called the AI software used in CubeFabs 'AIPC, a machine learning platform.' AIPC can map the entire CubeFabs and optimize production in real time. It also enables autonomous factory control, maximizing product yields, reducing waste, and reducing overall costs.

Nanotronics explained that the AI software suite available on CubeFabs will be priced at between $400,000 and $3 million (approximately 62 million to 462 million yen) depending on the sensor stream and data volume.

Each of the four manufacturing units has two clean rooms of 172 square meters each, which house the main production capabilities. Each manufacturing unit can also be fitted with shipping containers and trucks, ready for transporting the manufactured units.

However, each unit consumes 2.7 megawatts of power per day, meaning that a total of four of them consumes 8.7 megawatts of power. Technology media Tom's Hardware pointed out that CubeFabs' power consumption is so high that it 'may cause regulatory problems.'

Tom's Hardware wrote, 'We won't be using CubeFabs to build CPUs or GPUs any time soon. However, with the large amount of funding being pumped into CHIPS and the Science Act , the state government's expectations for manufacturing are likely to increase.'

If CubeFabs becomes a reality, many companies that have not been able to enter the semiconductor manufacturing industry will be able to participate in the competition. This will intensify competition in the semiconductor manufacturing industry, and it will benefit not only the United States but many other countries and regions. In fact, Nanotronics' business targets universities and companies that manufacture chips on-site.

Nanotronics explained that CubeFabs can be used for everything from full-scale R&D to production facilities, and that it can sustainably maximize manufacturing efficiency, making CubeFabs 1/100th the cost, 1/10th the size, and 1/5th the production time of a typical semiconductor fab.

Related Posts:

in Hardware, Posted by logu_ii