What is the secret hidden in the lid of Heinz tomato ketchup?

by

Heinz , the maker of tomato ketchup and other condiments, will introduce fully recyclable caps for its tomato ketchup products from November 2023 in an effort to help create a sustainable society. Lumafield , a company that produces industrial CT scanners, explains the structure of this cap.

Heinz's Sustainable Ketchup Cap

https://www.lumafield.com/article/heinzs-sustainable-ketchup-cap

Previous Heinz tomato ketchup caps were made from silicone, which made them impossible to process at some recycling facilities. However, the new caps are made entirely of polypropylene and can be accepted by all facilities that recycle plastics.

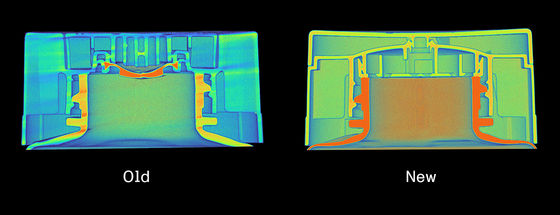

Below is an image comparing the conventional cap (left) and the new polypropylene cap (right). You can tell from the uneven color that the density of conventional caps is not constant. On the other hand, it can be confirmed that each part of the new cap has a uniform density.

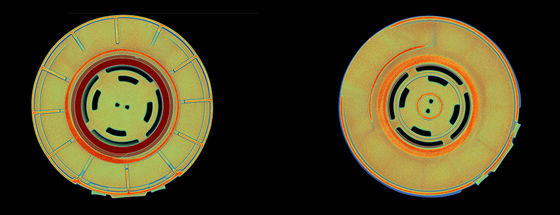

In addition to being easier to recycle, the new cap also makes it easier to pour ketchup. To squeeze out the ketchup, you need to press the bottle to apply pressure. When the bottle is squeezed, the ketchup inside is forced out of the bottle through the outer channel. At this time, the wall separating the outer flow path and the inner flow path not only prevents backflow but also makes it possible to apply pressure to squeeze out the ketchup efficiently.

In addition, it takes advantage of the property of ketchup, which increases in viscosity when pressure is no longer applied, to prevent dripping and staining of the cap.

Recyclable plastics generally perform worse than non-recyclable plastics, and reducing the amount of material used also reduces durability. Therefore, developing plastic products that can be recycled without compromising performance requires careful design and many tweaks. It is said that about 1.2 million dollars (about 176 million yen) was invested in the development of Heinz's recyclable cap.

Related Posts: