A 40-year-old PC is still in use at a hanten manufacturing site in Japan

At

A computer from 40 years ago is still in use! A Japanese factory that makes hanten while preserving tradition with machines and handwork - YouTube

Miyata Textile was founded in 1913 in Chikugo City, Fukuoka Prefecture. Everything from designing, weaving, cutting, and sewing is done in-house, and cotton-filled hanten, women's clothing, Samue, and jinbei are also produced in-house.

At Miyata Orimono, it was introduced how cotton-filled hanten is manufactured. An employee woman is trying to take out maxell's cassette tape and work.

Insert the cassette tape into the data recorder.

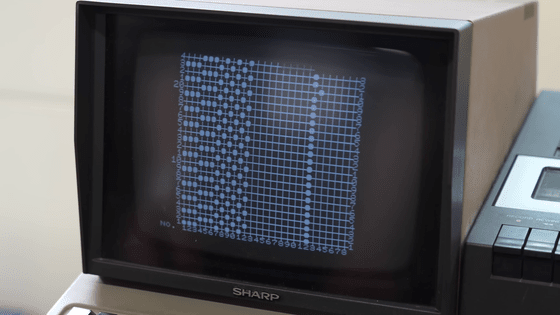

A system called 'AUTOMATIC PATTERN PUNCHING SYSTEM' will be launched.

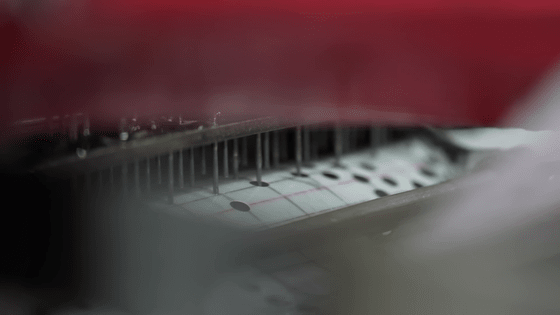

A pattern that appears staggered. Here, the design of the woven structure, that is, the design of the hanten, is done.

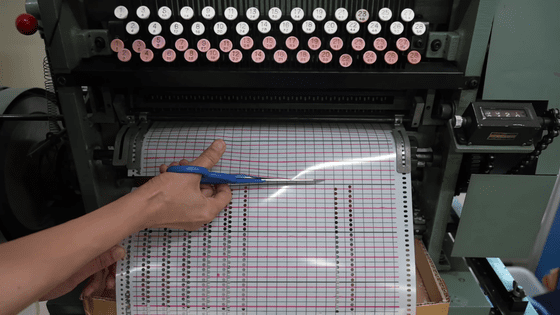

The punch machine rattles and outputs a punch card with the design in shape.

Cut the punched card with scissors.

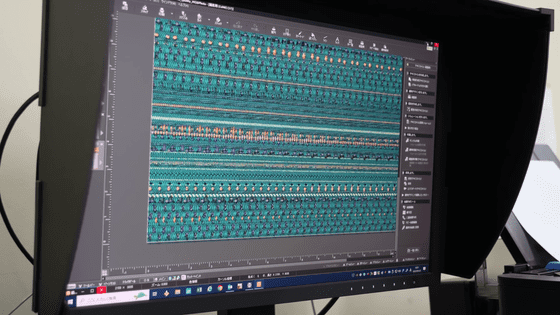

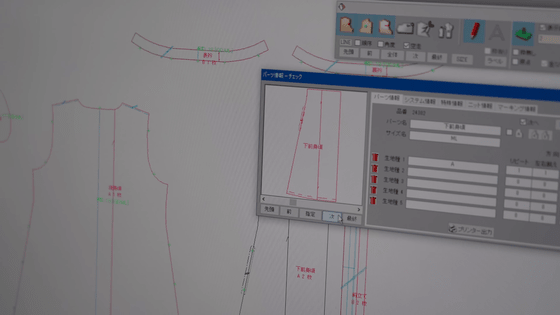

I decide on the design while realistically simulating the completed drawing of the fabric. It seems that the PC used for simulation is equipped with Windows 10.

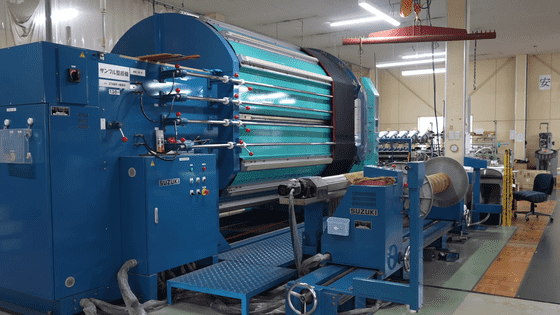

This is one of the machines that actually weaves textiles. The process called 'warping' to make the warp threads (vertical threads) begins.

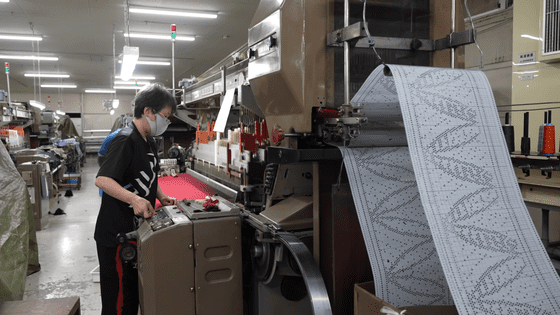

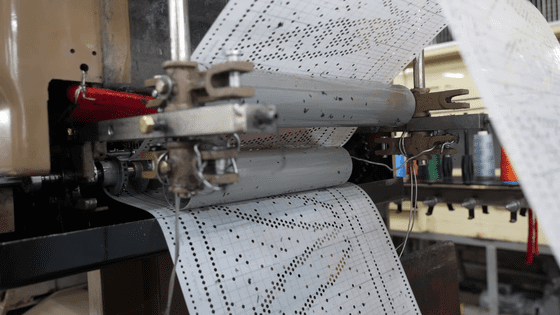

After the warp threads are wound around a part called a 'beam' and attached to the loom, the weft threads (horizontal threads) are inserted to weave the fabric. Punch cards are used here.

A long punch card.

The length of the punch card varies depending on the pattern of the fabric, and it seems that the longest one is about 10m.

A work called 'inspection' to visually check for color unevenness.

This is the process of designing the pattern (pattern) of clothes.

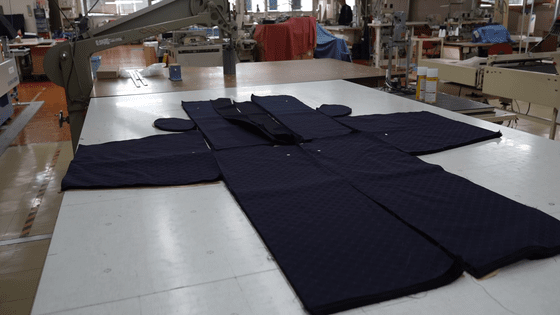

The fabric is cut according to the pattern.

'Sewing' to sew the fabric together is done by hand.

All the work to put cotton in is done by hand. I feel the beauty in the harmonious work of the two.

The collar is fastened with pins. At this time, it is said that cotton is added or reduced so that the thickness is uniform.

The final finishing is a process called 'hand binding', where each stitch is sewn by hand.

Visual inspection. You can check whether the cotton is evenly distributed and whether it is sewn properly.

Machine inspections are carried out to ensure that there are no needles or foreign objects mixed in with the product.

Finally, it is packed and shipped.

Miyata Textile's products are said to be finished with 'a special fluctuating design that can only be created by Miyata Textile' by combining the efficiency of machines with the laborious manual process.

Related Posts: