Amazon approaches the whole picture of its meticulous strategy that made its own container and avoided the turmoil of maritime distribution

Due to the increased use of shopping sites due to the new coronavirus infection (COVID-19), ships and containers are in turmoil at ports in California, USA, and distribution is delayed by several weeks. .. Meanwhile, CNBC, a news broadcasting station, is approaching what kind of method Amazon is taking to realize smooth delivery.

How Amazon beats supply chain chaos with ships and long-haul planes

At the Ports of Los Angeles and Long Beach in California, USA, the number of container ships waiting to enter the port is the highest ever, causing a delay in distribution. While this has reduced the expenditure of people to eating out and travel by the pandemic of COVID-19, expenditure of such appliances is that it because of the increase has been seen .

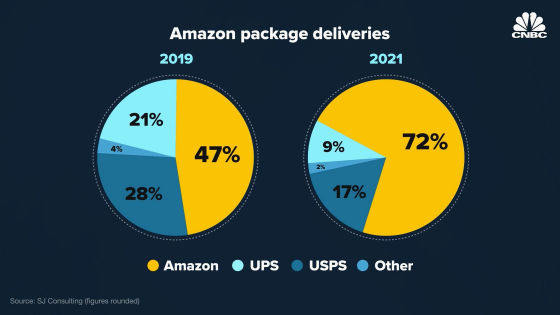

Amazon continues to realize quick delivery such as 'next day delivery' amid disruption of distribution and delays in product arrival. Amazon has been investing in delivering as many products as possible. In 2019, Amazon's shipping cost was $ 38 billion (about 4.3 trillion yen), but in 2021, that cost will increase to 61 billion dollars (about 6.9 trillion yen). Also, according to consulting firm SJ Consulting Group, among the packages handled by Amazon, the packages delivered from Amazon without going through a third party have increased significantly from 47% in 2019 to 72%.

One of Amazon's shipping strategies is to 'manufacture your own freight container in China.' It has been pointed out that there is a global shortage of containers as a cause of delivery delays, and container prices have risen to 20,000 dollars (about 2.3 million yen), which is 10 times that before the pandemic.

Amazon has manufactured 5,000 to 10,000 containers in China over the past two years and brought them to the United States. On October 5, 2021, it is known that Star Lygra, a cargo ship loaded with a large number of Amazon containers, arrived in Houston, Texas.

This is Amazon's own container.

Amazon is believed to have been investigating its own marine freight business in 2015. And in 2017, Amazon launched a global freight business through its Chinese subsidiary to promote

It is also reported that Amazon leases aircraft such as the Boeing 777 and uses it for delivery from China to the United States for the delivery of high-margin products. They also charter private freighters, carry their luggage to the port of Washington instead of the crowded Los Angeles, and then truck to Los Angeles.

It looks like this when loading and unloading luggage.

In addition, labor shortages have become a major logistics issue worldwide, but Amazon will hire up to $ 3,000 for all seasonal workers hired in 2021 to secure human resources. ) Sign-on bonus (lump-sum payment at the time of joining the company) is provided. The number of employees in 2021 is said to have increased by 50,000 compared to 2020.

Related Posts:

in Web Service, Posted by darkhorse_log