A man who made his own electric bicycle battery that can run 180 km with a few hours of charging appeared

With the shift from gasoline-powered vehicles to electric vehicles to address environmental issues, motor-

Long Range E-Bike · Jacques Mattheij

https://jacquesmattheij.com/long-range-ebike/

The Netherlands, where Mattheij lives, is a bicycle powerhouse, and it seems that more electric bicycles are sold than electric cars. In fact, Mr. Mattheij also has several electric bicycles, and the frequency of riding a car has decreased to less than half of the previous one. He also said that for Mattheij, who has a plate and screws in his legs in a car accident, an electric bicycle that is smoother to pull out than a normal bicycle is a good vehicle.

However, electric bicycles have the disadvantages that they have a slower top speed than cars and road bikes, and that they have a shorter cruising range due to battery problems. In fact, Mr. Mattheij said that he had the experience of running out of battery just by going when he ran a distance of 55km one way with the first electric bicycle he bought. After that, it seems that he began to carry a replacement battery, but Mattheij, who continued to be dissatisfied with the battery even with the electric bicycle he transferred, started a plan to make a large capacity battery himself and extend the cruising range.

First, Mattheij

Mr. Mattheij thought about using the BMS of the Bosch electric bicycle for the new large capacity battery, but Bosch's BMS has a system that prevents it from being used with a third party battery, and a cell is added to the existing battery. There was also a risk of failure if added. So Mattheij devised a system that combines an external battery balancer (a device that maintains the voltage of each cell) purchased from Ali Express with a Bosch BMS. I actually assembled a small battery using 10 cells and confirmed that the battery balancer and BMS work at the same time.

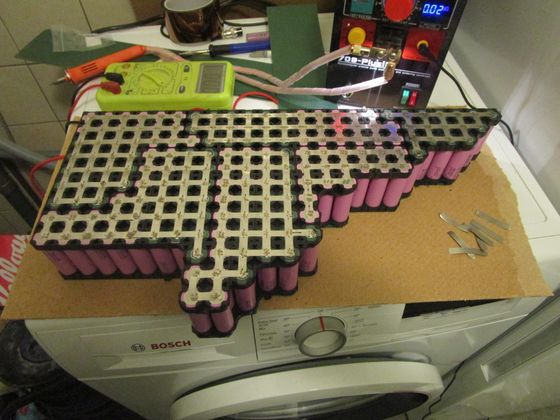

A typical electric bicycle battery is a collection of 40 to 50 cells of 18650 lithium-ion batteries (18 mm in diameter and 65 mm in length), but Mattheij says to increase the number of cells to make a large capacity battery. , I bought a total of 190 Samsung cells for about 600 euros (about 78,000 yen). After that, he watched a myriad of YouTube videos about cell-combined battery manufacturing, spot welding techniques, troubleshooting, and possible problems with homebrew batteries.

After watching some videos, Mattheij said connecting dozens to hundreds of batteries in series and in parallel is like working with a 'living bomb', which is pretty dangerous for you. He said he noticed that it was a difficult task. However, Mattheij did not interrupt the work due to this awareness, and decided to proceed with more caution.

Since the battery, which consists of 190 cells, is quite large, we initially devised a method of loading the battery behind the bicycle. However, when he actually loaded bricks instead of the battery and took a test drive, he encountered the problem that it was difficult to maneuver because the center of gravity was high and he was close to the back. As a result, considering safety, the battery was decided to be sandwiched in the middle of the frame, and the number of cells used was reduced to 170 instead of 190. The image below shows the battery box fitted into the frame before production.

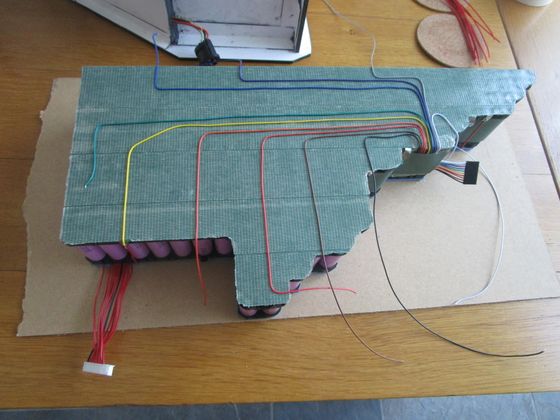

Mattheij, who made the battery box out of a non-conductive resin plate, went into the dangerous task of binding the cells of a lithium-ion battery. Since I understood the danger from YouTube videos etc. in advance, I first carefully considered the wiring, dimensions, number of cells, etc. of BMS and battery balancer, and before combining 10 cells as one pack, totaled He states that he checked the capacity and internal resistance of 170 cells twice to see if there were any problems.

And when welding the pack, he connected the welding machine to the socket to which the oven that can supply the largest power in the house is connected, and he worked on the oven. In addition, welding was carried out at night when the electricity consumed by neighboring houses was small so as not to interfere with the power supply as much as possible.

This is a battery that actually connects 170 cells and wires a balancer and BMS. It has a shape that matches the frame.

It looks like this when you put it in a resin box. When I tried the first charge and discharge, it seems that the capacity reached 2150Wh, which is almost four times that of a normal electric bicycle.

Mattheij put the battery he made on an electric bicycle and conducted the first test in November 2021. Then, the fully charged battery did not run out even if it went back and forth between my home and the city 65 km away. 'That is, we were able to run a total of 130km in just a few hours, and this bike is a viable alternative to a car. It's a bit slower (compared to a car) and can't carry that much luggage. But it's much cheaper and more climate friendly, 'says Mattheij.

Subsequent tests show that the cruising range on a full charge reached 180km and exceeded 500km in 'eco' mode. At the time of writing the article, it is still 'experimental', and the battery lid is clunky closed with tape, but after one month, check the battery status and if there is no problem, polish the whole and officially It is said that it will be installed in.

Related Posts: