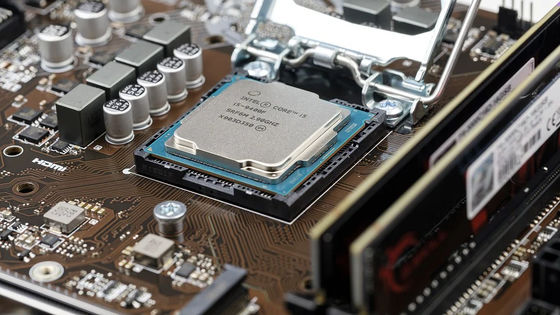

It turns out that Intel plans to invest more than 2 trillion yen to build a semiconductor factory in Europe

As the global semiconductor shortage continues, Intel CEO Pat Gelsinger has announced plans to build two semiconductor factories in Europe at a cost of $95 billion (approximately 10.49 trillion yen). . At the same time, CEO Gelsinger also talked about expanding production capacity for automotive chips

Intel to Invest Up to $95 Billion in European Chip-Making Amid US Expansion - WSJ

https://www.wsj.com/articles/intel-plans-investment-of-up-to-95-billion-in-european-chip-making-amid-us-expansion-11631027400

In July 2021, it was reported that Intel was planning to invest $20 billion (approximately 2.2 trillion yen) to build a semiconductor factory in Europe. CEO Gelsinger also attended talks about the global semiconductor shortage with French President Emmanuel Macron and Italian Prime Minister Mario Draghi.

Intel requests EU countries to invest in 2.2 trillion yen factory construction and provide site, plans to expand semiconductor manufacturing business widely in Europe - GIGAZINE

CEO Gelsinger, who attended the International Auto Show held in Munich, Germany in September 2021, revealed that he plans to invest $95 billion to build two semiconductor factories in Europe. In addition, it has been revealed that the factory construction plan still has the possibility of expansion. Regarding the plant construction in Europe, CEO Gelsinger said, ``In a new era where demand for semiconductors continues to increase, we need bold and big ideas.''

Furthermore, CEO Gelsinger also announced that the production capacity of the Irish semiconductor factory will be concentrated on the production of automotive chips. According to CEO Gelsinger, semiconductor costs, which accounted for 4% of vehicle production costs in 2019, are expected to reach 20% by 2030 as functions that require processing power, such as driver assistance functions, increase. It is expected. CEO Gelsinger said, ``The automotive chip market is expected to grow more than twice its current size over the next 10 years,'' highlighting the company's focus on producing automotive chips.

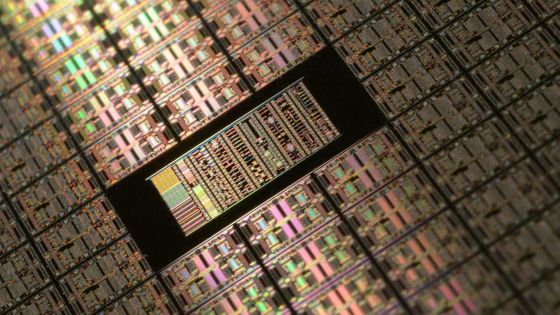

In addition, the semiconductor industry is moving to increase its production capacity in order to meet the ever-increasing demand, and TSMC has announced

TSMC, the world's largest semiconductor manufacturing foundry, begins construction of Arizona factory - GIGAZINE

Related Posts:

in Hardware, Posted by log1o_hf