Technology to monitor biological data by printing electronic circuits on the skin at room temperature is developed

Lightweight and small wearable electronic devices are useful for monitoring various biological data, but in recent years, a method of 'printing electronic circuits on human skin to monitor the human body' has been sought. Research teams such as Pennsylvania State University have announced that they have developed a new technology for monitoring biological data by printing electronic circuits on the skin at room temperature.

Wearable Circuits Sintered at Room Temperature Directly on the Skin Surface for Health Monitoring | ACS Applied Materials & Interfaces

Engineers print wearable sensors directly on skin without heat | Penn State University

Print These Electronic Circuits Directly Onto Skin --IEEE Spectrum

https://spectrum.ieee.org/the-human-os/biomedical/devices/skin-circuits

Researchers have focused on sintering , which hardens solid powder aggregates by heating them at a temperature lower than the melting point, as a method of manufacturing highly flexible electronic circuits that can be applied to monitoring biological data. By sintering metal nanoparticles, it is possible to print electronic circuits directly on the surface of paper, cloth, etc., but there was a problem that the temperature required for sintering was too high for human skin.

The research team of Associate Professor Huanyu Cheng of Penn State University also once developed a flexible printed electronic circuit that could be used as a wearable sensor, but printed directly on the skin due to problems with the binding process of metal nanoparticles. It did not lead to the realization of the technology to do. It seems that a high temperature of about 300 degrees was required to sinter the silver nanoparticles used in electronic circuits.

'Clearly, the surface of the skin cannot withstand such high temperatures,' commented Cheng, who sought a way to allow sintering at lower temperatures. Then, by creating a layer of a substance called 'sintering aid' under the electronic circuit, we have developed a method to reduce the amount of energy required to bond silver nanoparticles in the electronic circuit printed on it. did.

The sintering aid developed by the research team is composed of biodegradable polymer paste, which is the main component of peelable face masks, and calcium carbonate, which makes up eggshells. The layer of sintering aid is said to alleviate the negative charge accumulated by the silver nanoparticles and reduce the amount of energy required for sintering. 'We found that we were able to sinter silver nanoparticles at room temperature after making changes to the components of the auxiliary agent layer and the printing material,' said Cheng.

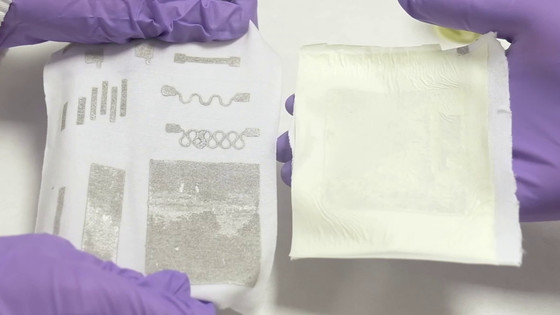

Furthermore, by printing the electronic circuit on a smooth sintering aid layer instead of suddenly printing the electronic circuit on uneven skin, the electromechanical performance when the electronic circuit bends or breaks. Seems to have improved. The layers of sintering aids and electronic circuits can be printed on clothing and paper as well as human skin.

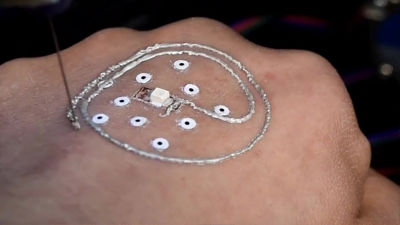

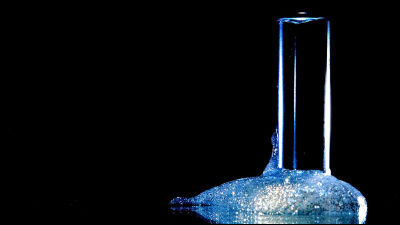

The research team actually conducted an experiment in which an electronic circuit consisting of silver nanoparticles and a layer of sintering aid were placed on a wooden stamp and pressed against the back of a human hand. After pressing the electronic circuit and sintering aid onto the skin, the research team said that they succeeded in sintering the electronic circuit of silver nanoparticles at room temperature by blowing air with a cold hair dryer to evaporate the solvent. I am reporting.

The electronic circuit actually printed on the skin looks like this. It seems that the electronic circuit after sintering was able to measure body temperature, skin moisture, blood oxygen, heart rate, respiratory rate, blood pressure, electrocardiogram, etc. Cheng states that the accuracy of the data measured by electronic circuits printed directly on the skin was equal to or better than that of traditional skin-mounted sensors.

The electronic circuit printed on the skin can be wet with water, but it can be easily removed with hot water, and once removed, it can be recycled again. Cheng argues that it can be applied to older people and babies as it does not damage the skin when removed.

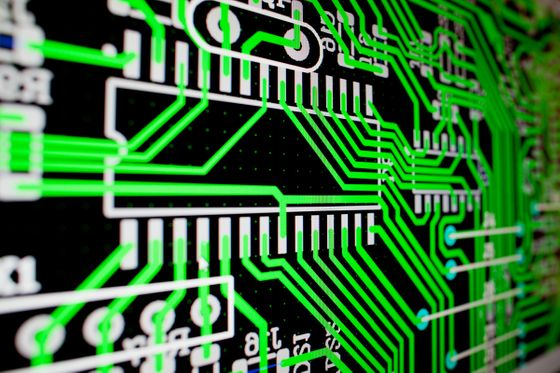

The research team also used a similar technology to print an electronic circuit on paper and create a simple board with a commercially available wireless communication chip added to it. We also showed that by sticking this simple board inside the sleeve, we could collect data from the sensors of the electronic circuit printed on the skin and send it to another device.

'Our approach uses a new sintering aid layer that allows metal nanoparticles to be sintered at low or room temperature compared to alternative approaches that require hundreds of degrees Celsius. Sensors that print on the skin have better signal quality and performance than commercially available wearable electronic devices, and can be combined with other expansion modules to replace wearable electronic devices that monitor health. ' It was.

Related Posts:

in Science, Posted by log1h_ik