Making masks is more difficult than you might imagine, why?

Coronavirus Spurs Demand For Face Masks — But They're Surprisingly Hard To make: Goats and Soda: NPR

https://www.npr.org/sections/goatsandsoda/2020/03/16/814929294/covid-19-has-caused-a-shortage-of-face-masks-but-theyre-surprisingly-hard-to- mak

The National Development and Reform Commission of the People's Republic of China announced at the end of February 2020 that `` the mask production capacity has reached 110 million pieces per day '', but textile products such as diapers and sanitary napkins have been issued by authorities' orders. Not only companies that manufacture, but also companies that manufacture shoes , iPhones , and cars are included in the 'mask business'. We continue to enhance our mask production capacity.

Mercury Home Textiles, a Shanghai-based bedding company, has begun manufacturing protective clothing in just a few days, under the direction of the Shanghai authorities. In less than a week, she

However, as many manufacturers turn to the mask business, NPR points out that it is difficult to produce high quality masks. Of the 200 million masks produced daily by China, only 600,000 N95 masks are available to healthcare professionals, according to the China National Development and Reform Commission. Authorities are attempting to increase production of the N95 mask, but 'failed,' the NPR wrote.

by

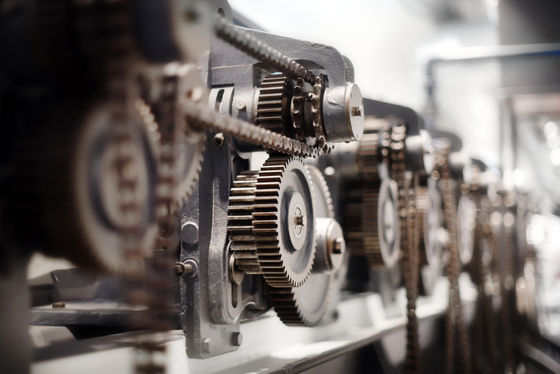

For the N95 mask, an ultra-fine fiber nonwoven fabric made by a method called ' melt blown ' is essential. The nonwoven fabric made by the meltblown process is woven with nano-sized fibers of less than 1 micron in diameter and does not pass harmful fine particles. However, industrial machines used for the melt blown process have a problem that they are difficult to introduce due to their performance.

Timothy Robson of Hills Inc. , one of the few companies in the world that creates the silicon dies needed for meltblown industrial machinery, pointed out the 'production line quality' problem in the Chinese manufacturing industry. 'Melt-blown industrial machines aren't just like' buy and use right out of the box ', like toasters. China has factories like the US and Europe, but it's a digging hut with bare ground, and it looks like it ships There's also a factory called defeat, 'said Robson.

by Kai Hendry

The problem is not just the quality of the production line. Haigong Machinery's Leo Liu, who imports and sells melt-blown industrial machines from the United States, Germany, and Japan into China, says, `` Melt-blown industrial machines take six months to manufacture and take one month to assemble after they are brought in. I need it. ' Although many manufacturers come to Liu to talk about mask production, they all seem to give up when they learn about the process and its costs.

As mentioned above, the number of industrial machines used in the melt blown process is limited in China. Therefore, NPR points out that the price of meltblown nonwoven fabrics is rising. 'Before the new coronavirus storm, meltblown fabrics were priced at less than $ 6000 per ton, but now 10 times that,' said Xuzhong Guohong, a Chinese supplier of meltblown nonwovens. To $ 60,000 (about 6.6 million yen), 'he said.

'Manufacturing is not easy: rings that catch on your ears, metal bands that make the mask stick to your nose, and packages,' said Shengjingtong's Chairman Guan Xunze, who produces 200,000 N95 masks per day. We need a huge manufacturing system. ' Although the company has been receiving meltblown nonwovens from local governments and is not affected by soaring prices for nonwovens, Xunze said, `` At the start of the business, there were 30 employees, but the local government 180 additional people have been assigned, 'he argued, with the government's instructions on management. 'There is little profit,' he said.

Related Posts:

in Note, Posted by darkhorse_log