How is Tabasco, which produces about 700,000 bottles a day, made? Surprising manufacturing process revealed in movie

A Look Inside the Mcllhenny Tabasco Factory in Louisiana-Eater

https://www.eater.com/2019/12/4/20995375/mcllhenny-tabasco-factory-red-pepper-sauce-louisiana

How the Tabasco Factory Makes 700,000 Bottles of Hot Sauce Per Day — Cult Following-YouTube

Tabasco was created in 1868 by Edmund Machirheny of Machirheny . Since then, Machirheny has been producing Tabasco with descendants of Machirheny.

When Tabasco was born, spicy sauce was not the mainstream. Fast food, like the

The appearance of Tabasco has revolutionized the American food culture, and has spread the pungent seasonings to the world, greatly affecting production and distribution.

The following image shows

Tabasco Pepper is the first plant made by Machirheny. Tabasco sauce will be made in about five years, including cultivation and aging.

Interviewer Daniel Jenine is on the left. To the right is Harold Osbourne, the CEO of Machirheny and his grandson. According to Osborne, Tabasco's manufacturing process has been automated in some of its processes, but the way it is made has not changed much from the original recipe invented by Machirheny.

Osbourne responded to Jenine's question, 'Are you using an economically efficient pepper?' Tabasco pepper is one of the smallest peppers in the country. Harvesting is still hand-picked in 2019, when the interview was held.

Jenine tastes Tabasco Pepper. It seems like I can't talk.

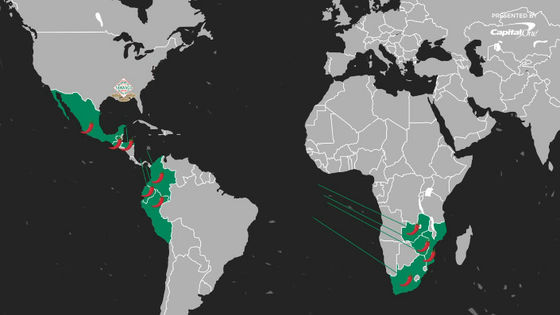

Seeds are collected from a large tabasco pepper field on Avery Island, and only the top 1% of quality seeds are exported to contract farms abroad for cultivation.

Species selected on Avery Island are sent to contract farms in Louisiana, Mexico and Venezuela ...

They can be raised on farms around the world.

Tabasco peppers are harvested in various places and salted and ground as soon as they are harvested.

Tabasco pepper in paste form.

The tabasco pepper is then sent to Machirheny, Avery Island.

The tabasco pepper in paste form is transferred to barrels. It is said that the transfer to the barrel is being done by one person, Stefan Lopez, who is in charge.

According to Lopez, about 100 barrels (about 15,900 liters) of tabasco pepper are packed in barrels a day.

Daniel, who tasted the paste Tabasco Pepper, commented, 'It tastes like fresh chili.'

The barrel is tightly covered with a hammer ...

The lid is covered with a lot of salt.

By covering with salt, even if there is a gap in the lid of the barrel, the grains of salt enter the gap and can be securely sealed.

Tabasco peppers in barrels are laid in storage for three years. It seems that about 55,000 barrels are stored in the storage.

Harold says that one barrel contains Tabasco pepper, which is the raw material for about 10,000 Tabasco.

The following image shows the contents of the barrel after 3 years. During the fermentation process, most of the water is drained.

Daniel, who ate the fermented Tabasco pepper, commented, 'It tastes like miso.'

The fermented Tabasco Pepper goes to the blending process, which is the final stage of making Tabasco, in a room called a mixing room.

Morris Montgomery, responsible for the blending process.

According to Montgomery, the mixing room mixes tabasco pepper and vinegar over a couple of weeks.

Every day, McKillheny sources about 12,000 gallons (about 45,400 liters) of vinegar. It is said that purchasing will be done by two trucks because of the large amount.

Tabasco does not classify Tabasco Peppers by country of origin for consistency of quality. All tabasco peppers are mixed at once to make tabasco.

During an interview in the mixing room, Daniel complained, 'The nose is quite stimulating,' and the smell in the room seems to be quite strong. However, Mr. Montgomery said, 'I will get used to working for several years,' and he seems to be fine.

It takes about three weeks to remove impurities from the thoroughly mixed tabasco pepper and vinegar.

About 12 barrels (about 1907 liters) of Tabasco pepper and vinegar remove about 1500 pounds of seed and flesh. The pulp is only about 40 pounds (about 18 kg), and the impurities seem to be mostly seeds.

Tabasco is completed only after the impurities are removed.

The completed Tabasco is taken to the laboratory for quality inspection. We test the quality of salinity,

'Since we only make good Tabasco here, the test will be good,' says Montgomery.

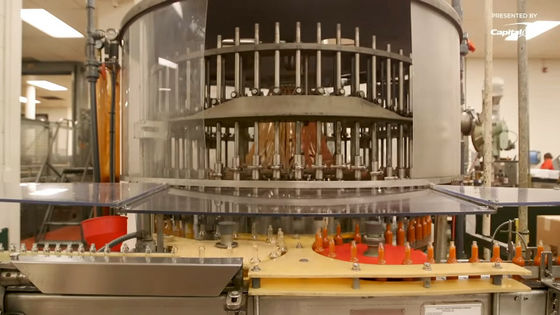

If there is no problem with the quality inspection, we move on to the bottling process. Tabasco is poured into the bottles one after another by the machine.

The cap is closed ...

Packed in a box.

Tabasco packed every 12 pieces.

Tabasco, completed through a number of processes, is exported from Avery Island to the world.

John Simon, who is in charge of the bottling process, said he is a relative of Machirheny.

According to Simon, Machirheny made about 350,000 tabascos in his lifetime. However, it seems that Makil Henny in 2019 may produce about 700,000 tabascos twice that time in one day.

The plant is operating five days a week, producing Tabasco almost 24 hours a day.

After looking at the factory, Jenine said, 'It has become very popular over time since Tabasco's birth. I believe that consistent production consistency has always been very important. , Run by the descendants of Tabasco's creator, Machirheny, and everyone who works at Machirheny, has inherited the founder's wishes and has been passionate about making Tabasco. '

Related Posts: