World's first 'Intelligent Valve Actuation' to completely control engine valves with digital technology is developed

The 'Intelligent Valve Actuation ( IVA )' system that operates the intake and exhaust valves that are arguably installed in gasoline and diesel engines with only the power of an electric motor is a British engineering company 'Camcon Automotive' Developed by In conventional engines, the crankshaft rotation was taken out to drive the valve, but in the IVA, the electric motor can be controlled freely by controlling the rotation of the electric motor without using even a metal spring.

World's first fully digital valves open up engine possibilities

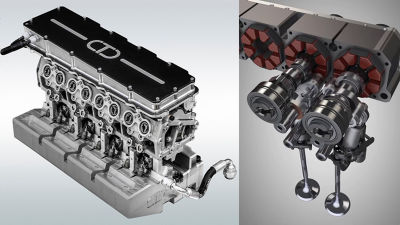

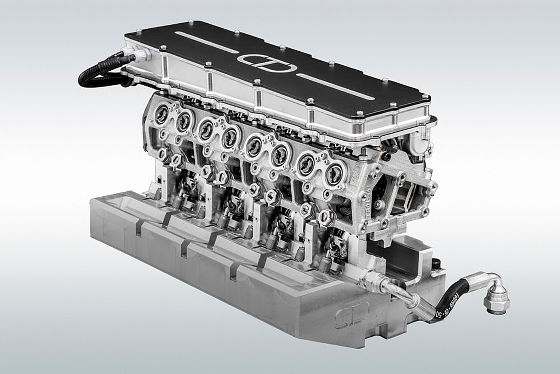

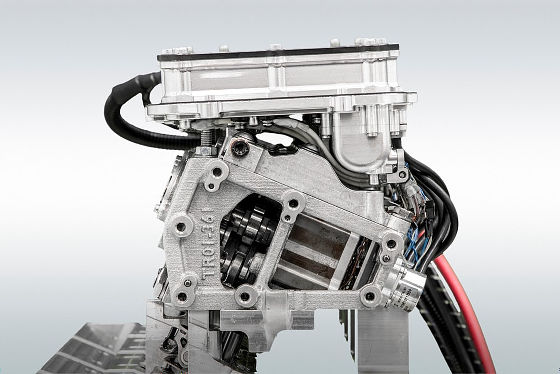

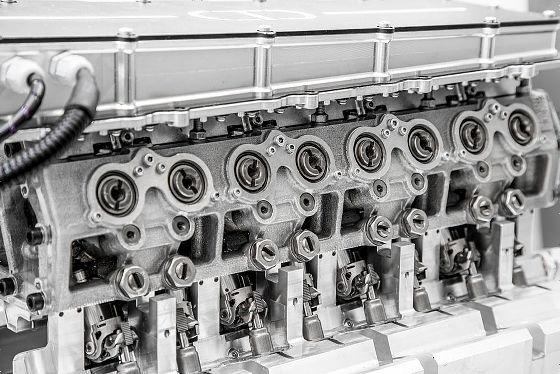

The IVA was developed by Camcon Automotive with 'a device completely compatible with existing engines' in mind. The following photo is not the whole engine, but the part corresponding to the 'cylinder head' where the cam mechanism is put together. This is a device for controlling only the valve on the intake side.In the case of a normal cylinder head, one or two 'camshafts' penetrate in the longitudinal direction to drive the valve, but this IVA The cylinder head does not have such a mechanism, but instead has eight rotating parts.

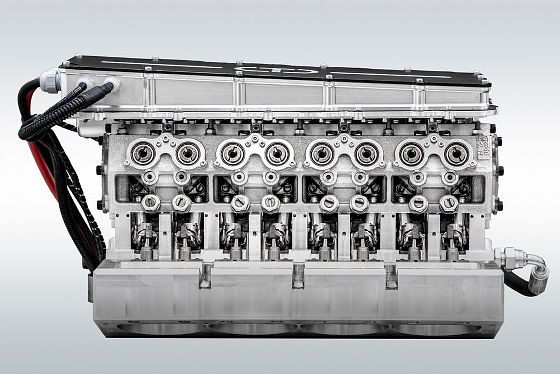

Looking from the side, you can see that the electric motor is installed on the right side as viewed. The electric motor is equipped with an electric cable for control and is connected to the case above the cylinder head that contains the electrical system.

In the following movie, it is possible to get a little glimpse of how IVA works.

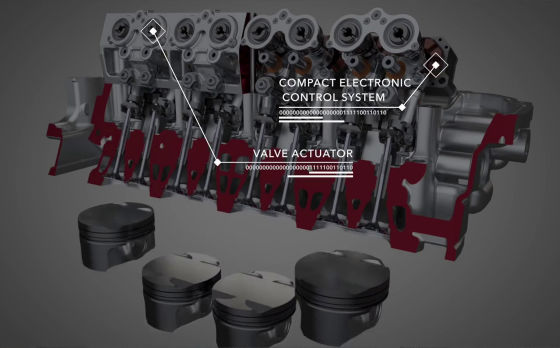

Mark Gostick, Commercial Director of Camcon Automotive. 'IVA removes the conventional camshaft to enable highly flexible valve control by digital control. It digitizes the analog mechanism' intake 'remaining in internal combustion engines.'

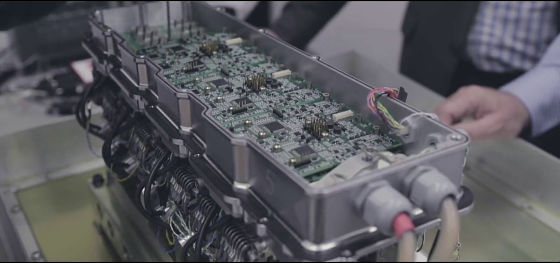

Electrical system built into the head. The idea of electronically controlling valves has existed until now, and a

Roger Stone, Technical Director of Camcon Automotive, cites the benefits of IVA as 'very flexible valve control.' The variable valve timing system that began with Honda's 'VTEC' has made it possible to approach the optimal valve timing according to the engine speed, but it has not escaped the restriction of 'camshaft drive' .

IVA completely removes that restriction, allowing you to open the valve when you want to open it and close it when you want to close it.

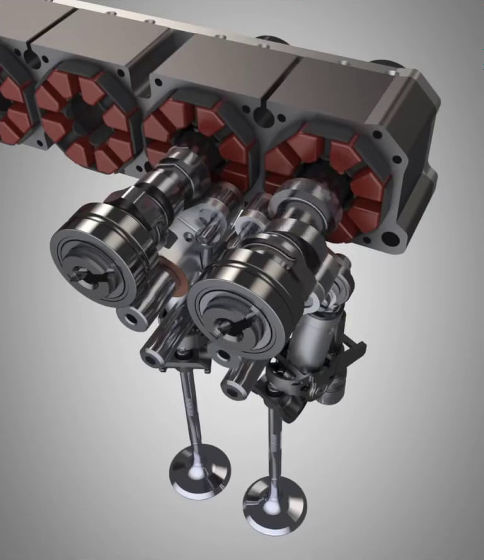

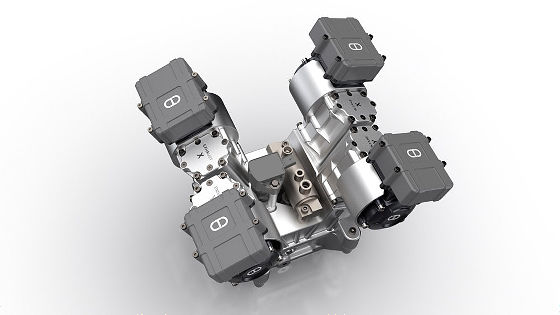

The drive unit looks like this. A drive shaft that extends from a high-torque motor on the other side pushes the valve down and pulls it up. This mechanism that controls the opening and closing of the valve without using a metal spring is called the 'desmodromic mechanism.'

The opening and closing timing of the valve is controlled by the rotation of the motor, while the opening and closing amount (= lift amount) of the valve is controlled by the rotation angle of the drive shaft. If you want to open the valve 100%, rotate the drive shaft 360 degrees, but if you want to open it slightly, such as 50% or 10%, do not fully rotate the drive shaft, for example, rotate from 0 to 120 degrees It seems that the valve is slightly opened and closed when the motor is rotated in the reverse direction.

The eight largest circular parts are the drive shaft. The other side is connected to a high-torque motor, and the shaft can be freely rotated forward and reverse to achieve the desired valve opening / closing timing and lift amount.

Camcon Automotive is developing an IVA in collaboration with Jaguar Land Rover, and has already been conducting demonstration tests for more than 1,000 hours with the IVA installed on the Jaguar Land Rover engine 'Ingenium'. Test runs with an IVA installed on the intake side showed a 7.5% improvement in CO2 emissions and improved fuel economy. In addition, further adjustments in the future can be expected to improve performance by up to 20%.

The IVA will literally give you complete freedom to control the valve movement, making it possible to increase the efficiency of the engine more than before. In addition to valve control according to the engine speed, it is also possible to increase efficiency by reducing the resistance by moving only the necessary valves when starting the engine. Furthermore, by controlling the valve timing, a 4-stroke engine can be operated in a state close to a 2-stroke engine to increase efficiency, and conversely, by realizing a '12-stroke engine', it also increases efficiency. Is considered. And, of course, it is possible to increase the efficiency of the engines used in hybrid vehicles.

The idea of “electric valve control” has existed before, but the opportunity to realize IVA at this timing was `` Because the technology and electronic devices just to realize it have developed. ' Although the world of automobiles is showing a major shift toward electric vehicles (EVs), there seems to be room for performance improvements in conventional internal combustion engines.

Related Posts: