How is Nikon's prestigious lens brand "Nikkor" made?

byRafael Castillo

Camera maker ·NikonThe lens brand of Nikkor (NIKKOR) is. There are fans in the world with high quality. It is in Yuzawa City, Akita Prefecture, that manufactures optical lenses that support this high qualityLight Glass Co., Ltd.is. Report infiltrated to the factory, camera review ·Imaging ResourceI visit and I am publishing a report.

Glass for geeks: An in-depth tour of Nikon's Hikari Glass factory

https://www.imaging-resource.com/news/2018/04/17/glass-for-geeks-an-in-depth-tour-of-nikons-hikari-glass-factory

Factory of Hikari Glass Co., Ltd., which is made up of Nikkor lenses, models of lenses such as microscopes and binoculars. Yuzawa City, Akita Prefecture, where the location is located, is a heavy snowy zone on the Japan Sea side, and serves as editor in Imaging Resource for snow cover exceeding 1 meterDave EchelleI was surprised to hear that.

The important thing in making Nikkor lenses is to thoroughly mix materials such as quartz, sodium carbonate, potassium, lime, and so on, to blend perfectly.

The mixing work is handled by a huge mixer. You can see in the following movie how to mix materials while rotating.

Nikon Hikari Glass Factory - Y - Mixer - YouTube

Mixed materials are melted in a high temperature furnace made of the same quartz as the glass main material. The quartz furnace seems to melt very slightly due to the high temperature, but the amount that the furnace melts and is mixed when preparing the material is also calculated. Although it is said that photography was prohibited in the furnace and the melting process, the appearance of pouring molten glass into the mold is published in the following movie. .

Nikon Hikari Glass Factory - Tapping The Crucible - YouTube

Impurities and foreign matter mixed in the molten glass cause air bubbles, but slight bubbles are not allowed with lens glass. For this reason, we devised measures to dissolve the glass while changing the temperature so that bubbles do not enter. The width and the thickness are different according to the size of lens to make.

The glass that has flowed through the belt conveyor is cut to the size determined by the hand of the craftsman. "I was surprised by the craftsmanship that cuts precisely without breaking the glass into pieces with small hammers and glasses," Echelle says.

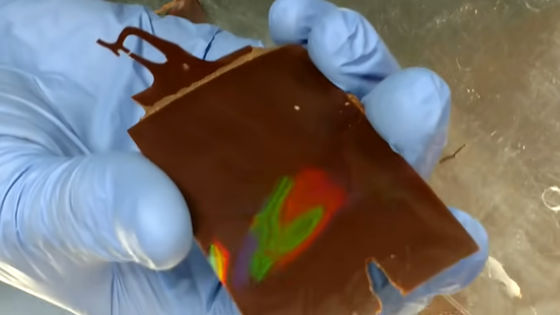

Visually inspected glasses are carefully checked, "Are there any bubbles in it?" Or "No unevenness in ingredients". The following image is where the glass plate is passed through to the light and checked for bubbles.

Also, unless it mixes well in the crucible of the furnace, the ingredients can be uneven and the refractive index will change depending on the location, so it can not be used for lenses. Move the glass in various directions while projecting the light, carefully check the contrast of the light and dark to find the unevenness of the ingredients.

Because the refractive index of glass is very important for lenses, we measure not only by visual inspection but also by machine. Also, not only the refractive index but also the transmittance of light is measured, and the transparency of the glass is also checked.

Glass that passed through a tough check will be processed into dice shape. For that purpose, we first divide the glass plate into two vertically, but this process is done manually. There is no blade on the rotating disc, and it can cut cleanly with frictional heat.

The cut glass is like this. "Crystal glasses used for chandeliers and wine glasses have a radiance like diamonds due to their high transparency and refractive index and have been treated like gems.The glass made for lenses also has transparency and refraction Due to its high rate, it shows a brilliant radiance that seems to be accessible to women's accessories, "Echelle comments.

The cut glass dice are put into the vibration barrel. Small rocks, abrasives, and a small amount of water are contained in the vibrating barrel, and the glass dice are scraped to an appropriate size.

The state that the glass is actually polished by the vibration barrel is released in the following movie.

Nikon Hikari Glass Factory - Vibratory Tumblers - YouTube

There are various types of polishing machines besides the vibration barrel, and it is said to be used properly according to the type of glass. After the polishing is over, the glass which is totally rounded is like this.

After the polished glass is carefully checked whether it is not chipped, it is pre-molded into a shape close to the lens. After the glass is coated with boron nitride powder, it is heated in a high temperature furnace, it is pressed into a mold, and it is molded into a shape close to the lens. The layer with boron nitride is removed in the lens polishing process.

The process of preliminary molding is done not by machine, but by 2 to 3 craftsmen by hand. The timing of taking out the glass from the furnace is said to be judged by experience of craftsmen. You can check the work process of preforming the lens in the following movie.

Nikon Hikari Glass Factory - Pre-forming Press - YouTube

Further checking is done visually by checking whether the preformed lens is free of cracks or distortion. Only those that passed this will be sent to the Nikon lens factory.

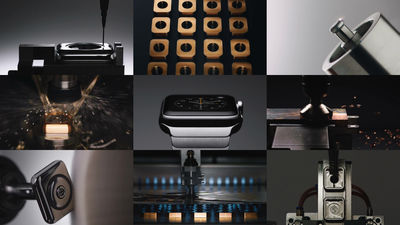

The lens which preliminary molding is over and the check passed also looks like this. The shipped lens balls are polished and assembled at the lens factory. Echelle says that there is a long and complicated process in the manufacture of Nikkor lenses, and that Nikon can have its own charm not found in other camera manufacturers.

Related Posts: