A magnificent project "MX3D Bridge" to put a steel bridge printed with a 3D printer

I will print my whole house with a 3D printer and make itIn the construction industry, such as 3D printers, the spread and use of 3D printers are progressing. "MX3D Bridge"Is a project to print all metallic bridges with 3D printers, the bridge which is actually made in" MX3D Bridge "and is scheduled to be put into a canal flowing in Amsterdam in the Netherlands was almost completed at the end of March 2018 It is.

MX3D Bridge

http://mx3d.com/projects/bridge/

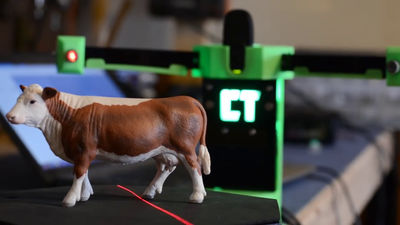

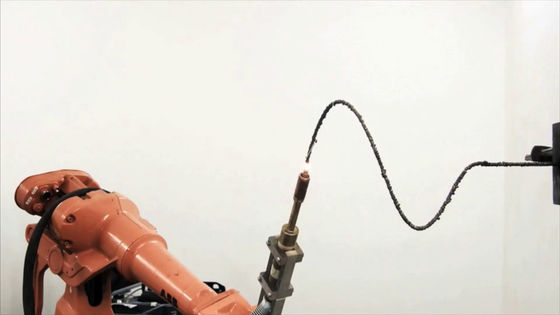

What is promoting "MX3D Bridge"MX3DIt is a Dutch venture company. The 3D printer developed by MX3D is a 6-axis industrial robot attached with a welding machine, it is possible to output a metallic object three-dimensionally in the air.

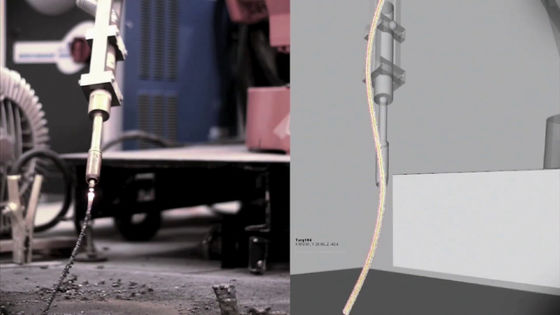

The robot arm moves as simulated by the PC.

I am prototyping a small bridge of wire frame with a 3D printer.

A small bridge does not break even if a human rides, and seems to be made strong enough.

In October 2015 the project "MX3D Bridge", "Let's print all the steel bridges actually on the canal in the center of Amsterdam with a 3D printer"AutodeskYaLenovoIt was established with the cooperation of many companies such as.

In order to design and construct a bridge, we scanned the area around the planned bridge in 3D, and in May 2016 we incorporated it into the PC and provisionally determined the design of the bridge.

However, it is unknown how much the canal wall of canal with nearly 400 years history can withstand the load, and in order to respond to the complicated functionality and safety that the original design plan had, the current 3D Since it can not be processed with design software, it is forced to make a big change in design. As a result, it took nine months, from preliminary decision of design to final decision.

The following image is a reproduction of the final design of the bridge with 3DCG. By directly outputting with a 3D printer, it is said that the organic design which used many curves became possible, especially the swirling railings draw attention.

It was in March 2017 that 3D printing by four industrial robots began on quays reproduced in the factory. It took about a year to output the bridge little by little from both ends, and the bridge was connected at the end of March 2018.

Looking at the main part of the output bridge from above looks like this. The total length of the bridge is 12.5 meters and its width is 6.3 meters. A part of the balustrade part has not been output yet, but the body part is complete, you can see that it functions as a bridge connecting two shore.

Bolts and studs are not found on the bridge, and if you look closely at the surface, you can see countless traces of lamination by 3D printers. The interior of the bridge is a hollow, and it is said that reinforcing materials are loaded.

The output bridge is actually put in accordance with the canal revetment construction and it is scheduled to be released in June, 2018.

Related Posts:

in Hardware, Posted by log1i_yk