Pictures showing how natural crystals are processed as parts of radio equipment over 70 years ago

Quartz which also becomes a material of glass is crystallized into a hexagonal prism shapecrystalis. Crystal is a transparent, very hard ore, it carries various colors due to impurities in the crystal and "amethyst"·"Agate"·"Rose Quartz"It is called with various names such as. Crystals have been treated as gems since ancient times, but it is actually a very important ore as a material for parts of electronic equipment. Recorded images of the appearance of processing crystals as parts of military radio equipment 70 years ago from now are released publicly on YouTube as a public domain.

Crystals Go to War 1943 Reeves Sound Laboratories; Piezoelectric Quartz Crystals for Radio - YouTube

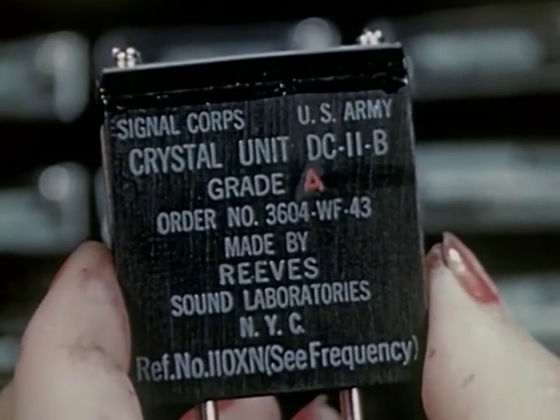

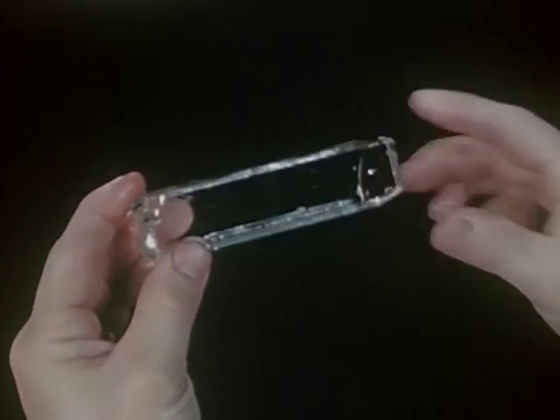

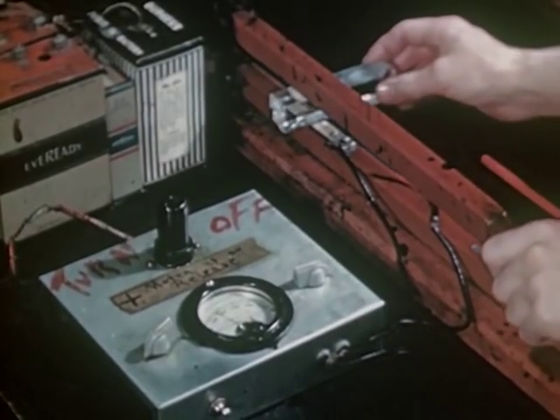

The crystal oscillator that was used in the US military at that time is like this.

Potential is generated when pressure is applied to some crystal bodies such as crystal. Conversely, if external voltage is applied to the crystal, natural vibration will occur. This phenomenonPiezoelectric effectIt is called a French scientistPierre CurieThey were discovered in 1880. With the discovery of this phenomenon, the crystal will be useful not only as a jewel but also as a material indispensable for military radio and submarine sonar.

Oscillation circuit using crystal produces stable frequency by piezoelectric effect, vibration mode largely changes depending on crystal cutting angle. For this reason, it is necessary to grasp the crystal structure of the crystal and cut it, rather than cutting out the crystal properly.

In modern times mass production of artificial crystals is possible, but in the 1940 's, mass production technology of artificial quartz has not been established yet, natural crystals had to be processed. First of all, we will select natural crystals from Brazil by size, shape, color, quality etc.

When it is submerged in oil, the shape of the crystal will not be visible because the refractive index of oil and crystal is close. Utilizing this phenomenon, light is applied to the crystal that is submerged in oil, and it is checked whether the inside of the crystal is scratched.

Check has finished crystal is submerged in again oil, this time will be confirmed the direction of the crystal structure.Light interference, The crystal structure becomes visible and the line to be cut is determined based on it.

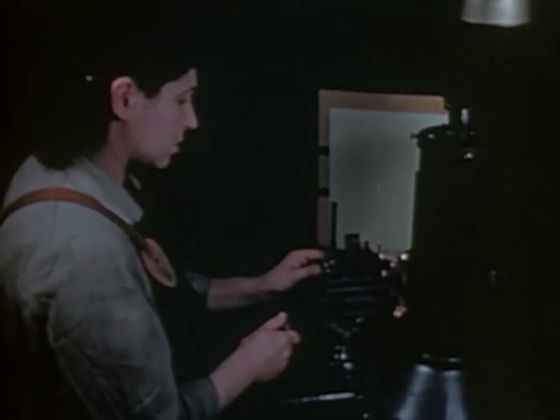

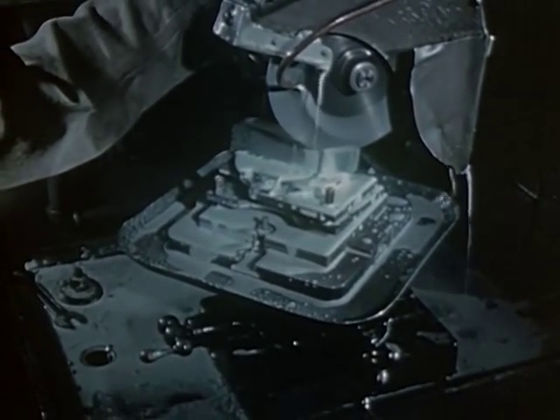

While checking the directions again and again, we will process crystal crystals into rods.

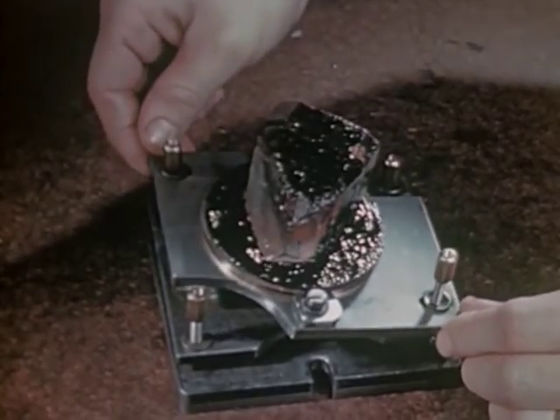

Pressure is applied to crystals of rod-shaped crystals, and it is investigating whether electric potential occurs properly.

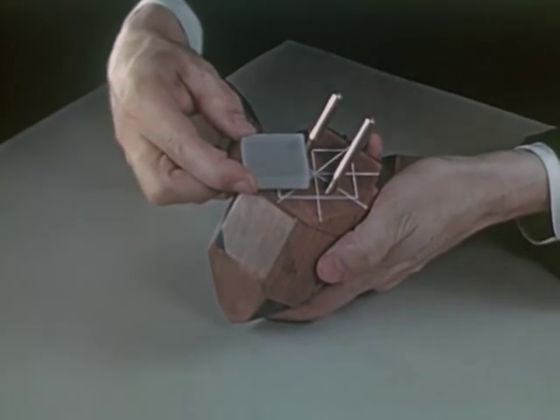

If there is no problem, you can make quartz crystal, special made with fine adjustment of tiltA jigAnd determine the direction in which the crystal is cut more precisely while checking with X - rays.

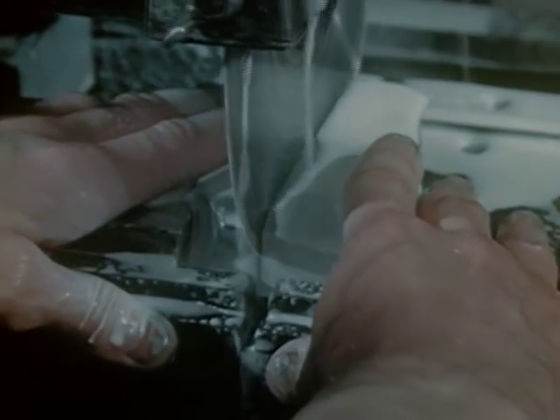

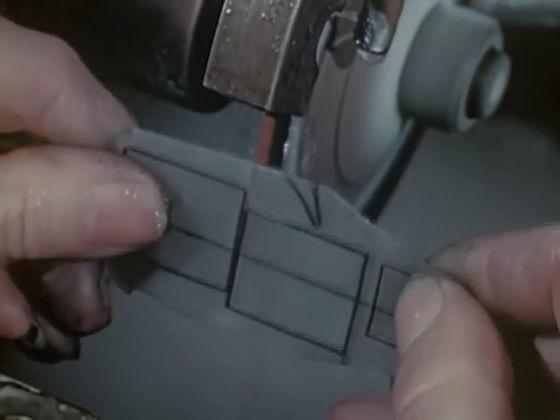

After the confirmation, the crystal is thinly cut.

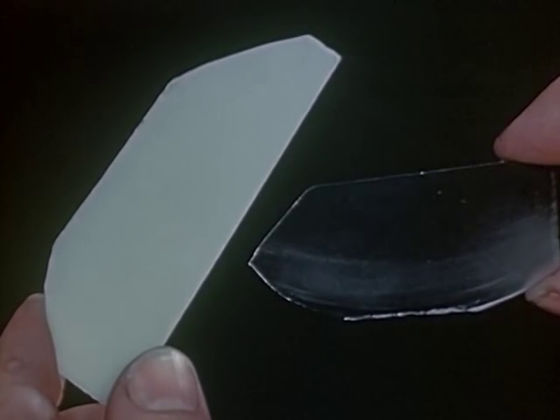

The cut crystal is subjected to chemical cleaning. Since the surface is eroded by acid, the crystal piece turns white and turbid. The left is a chemical-treated crystal piece, and the right is an untreated crystal piece.

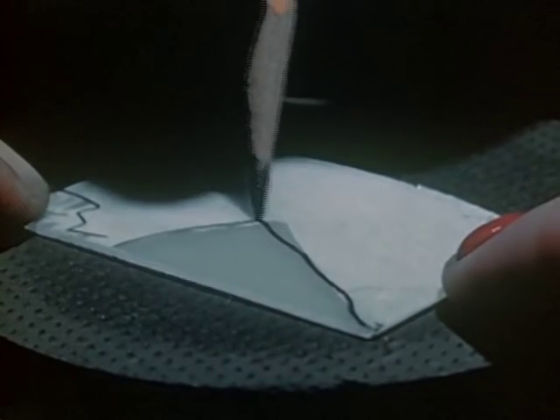

Apply light from various directions to the treated crystal piece and mark with a pencil on the part where the color changes. Since the crystal structure of this part has been misaligned, it is necessary to eliminate it when processing.

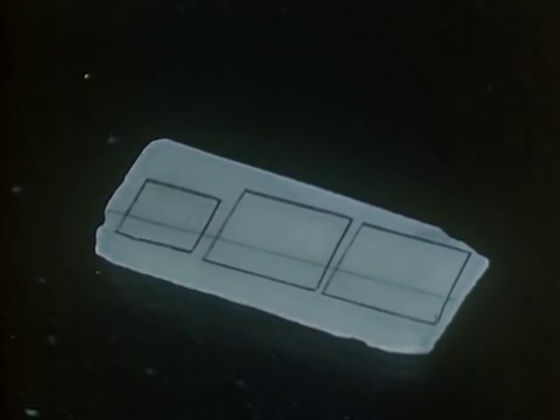

After checking the direction of the crystal piece while checking with a polarizer, draw a line with a square window frame.

The crystal piece is cut further along this line.

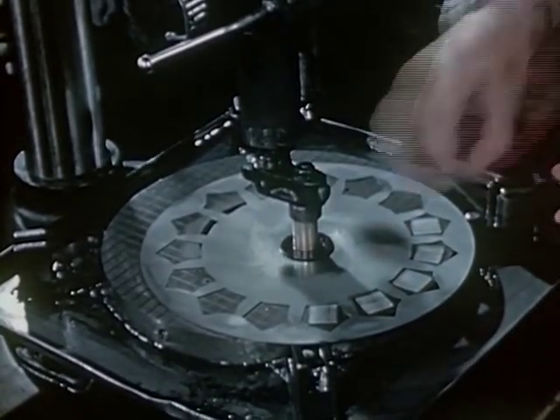

Put the cut crystal pieces on top of each other and cut the end with a spinning saw to make the size of the crystal pieces equal.

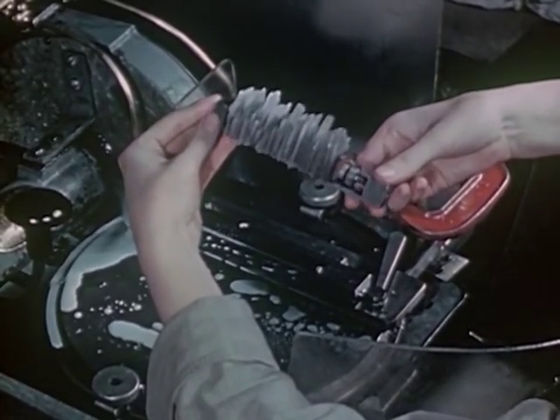

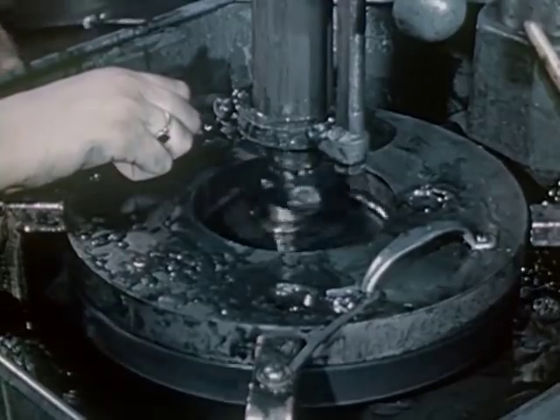

Further polish each crystal piece firmly and repeatedly with a polishing machine and dry it.

As the frequency of vibration changes according to the thickness of the crystal, we polish to the correct thickness while checking the frequency.

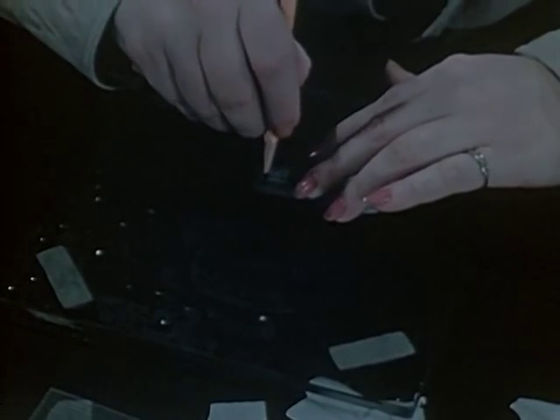

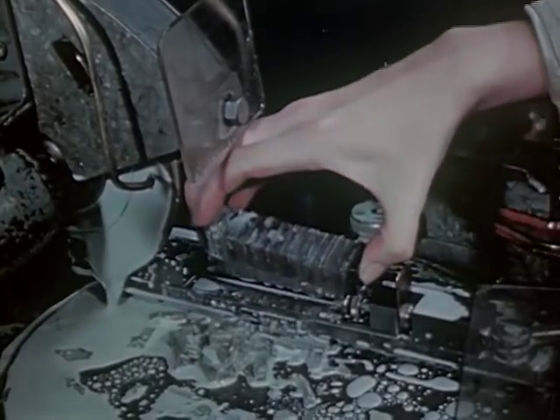

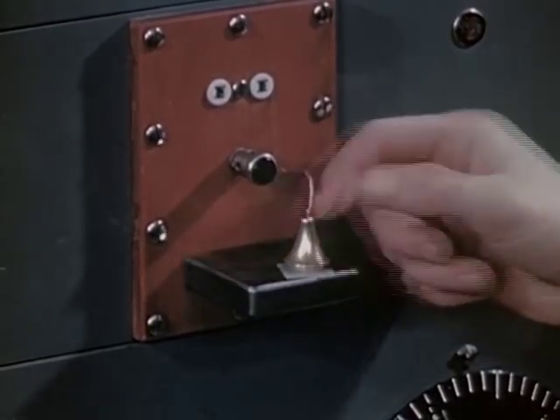

Once chemical washing is done again as a finish, we will incorporate the crystal blank into the oscillator.

And it will be completed by various tests including frequency check · vibration test · drop test etc. When you look at the movie, you can see that the production of crystal oscillator during World War II was very costly. The art of mass-production of synthetic quartz is established after the Second World War, even in Japan which mass-produced quartz watches and radio appliances such as radioMass production of authentic artificial quartz has been realized since 1973It is said that.

Related Posts: