A huge crane lifting 500 tons of luggage is assembled All the movies are spectacular

"Heavy machinery / construction machine" which carries heavy loads and assembles is one that has a charm that can not be said even. Self-propelled crawler crane of German construction machine maker · Liebherr (Rip Hell) "LR 1500"Is a large crane capable of lifting up to 500 tons of luggage. Furthermore, it is assembled in a single movie all the time when the crane capable of lifting luggage up to height of 164 meters is lifted by lifting boom which is about 150 meters in length, but while sandwiching a coffee break in the middle It seems that there is remarkable appearance for the construction machine lover as it is assembled.

Liebherr LR 1500

https://www.liebherr.com/en/jpn/products/mobile-and-crawler-cranes/crawler-cranes/lr-crawler-cranes/lr-1500/lr-1500.html

Liebherr LR 1500 is a large crane whose widths of the left and right crawlers are 7.6 meters. Although you can run freely, you can not run on a public road as a matter of course, so you can assemble it locally in a disassembled state to the construction site.

The following movies contain all the details that LR 1500 can be assembled.

Liebherr - LR 1500 crawler crane - YouTube

Parts of LR 1500 carried separately into multiple trailers

In the field, three staff members will be assembled.

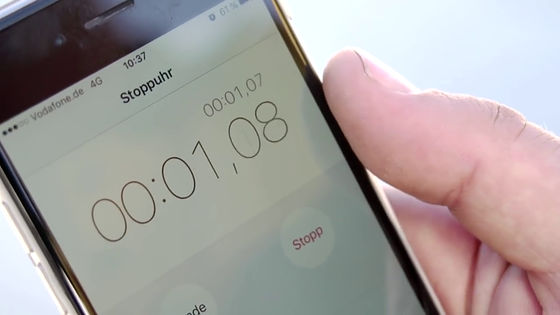

With the timer of the iPhone, we measure the time required for assembly.

First of all, we will lower the body of the crane that has been placed on the trailer.

Although it says "Lower", in fact the way to extend the leg from the body to the ground and extract the trailer below.

First of all, we attached the first boom (the hanging luggage arm) on the top of the main unit.

Using a hydraulic cylinder, insert a thick metal pin into the fulcrum of the boom.

Next, use the boom just installed, unload the crawler that was put on another trailer ... ....

I wore it on my leg.

I also install the other crawler with my own power.

After the crawler is installed, next we put the weight "Center ballast" to increase our weight. First of all, we will load a total of 40 tons of ballast at the bottom of the car body by 20 tons each.

In the case of the LR 1500 with a compact design, the top of the ballast is also used as a floor to access each part of the car body.

Next, a winch is installed to wind up the wire lifting the load.

And, an auxiliary winch used for another purpose than luggage lifting is installed.

Furthermore, by loading the ballast "upper swivel counterweight" on the left and right sides of the car body, we do not topple even if we lift a heavy object.

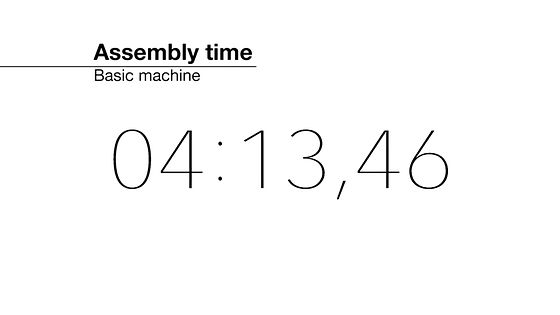

The elapsed time so far, about 4 hours.

A mobile cafe arrives

The worker took a breath here. It seems that the intention of "can be assembled in a relaxed state" is put in.

Work restarted after the break. Next we will attach the boom to the completed body. The boom is also delivered to the site in a disassembled state, and it is attached to the crane after assembly.

Boom installation complete. It looks like a crane is now created, but in fact the main boom has not yet been installed. The long boom I see now is what is called the "derrick boom" that supports the main boom.

Then assemble the main boom.

Attach an anemometer to measure wind speed at the tip ...

A long main boom started.

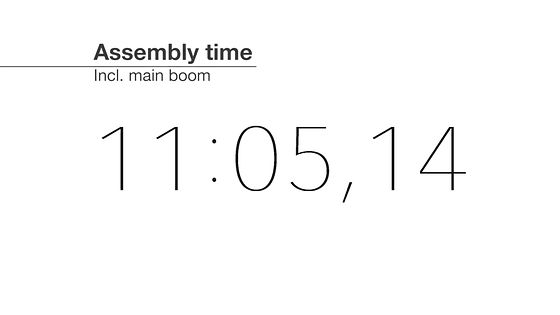

This completes the assembly process. The time it took so far was around 11 hours.

Next, build up the ballast on a big platform and create additional ballast. This ballast is suspended on the rear side of the car body and is called "float type ballast" which balances with luggage.

By installing this float type ballast, the maximum lifting weight (load capacity) will be 500 tons.

There are also ways to use the ballasted truck "Ballast trailer" for ballast installation. Although the names of the screen and Japanese are slightly different, the Japanese name is mainly aligned with the name of the document of Leapher Japan.

If you use the ballast trailer, you can swing the main body with heavy ballast loaded ......

It is possible to move with crawler while loading.

Furthermore, it is also possible to lift the cargo to a higher or far distance by attaching "undulating jib" to the tip of the boom.

First of all, install a short boom called "auxiliary jib" ......

Lift up with a little. And install the boom of the tip further ...

It is like this when raising everything.

LR 1500 with completed relief jib specification. Even in such a vast field, it is possible to carry baggage such as steel frames in a single unit and carry it over a wide area.

Related Posts: