Ionic Materials announced that it succeeded in developing a cheap and safe alkaline polymer battery manufacturing process than lithium ion batteries

High-tech products such as smart phones, notebook PCs, and electric cars are realized through the popularization of lithium-ion batteries. However, there are many disadvantages as well as merits of lithium-ion batteries, so the need for alternative batteries is screaming. America'sIonic MaterialsAnnounced that it succeeded in developing low-priced, mass-producible alkaline polymer batteries that replace lithium-ion batteries.

A Better, Safer Battery Could Be Coming to a Laptop Near You - The New York Times

https://www.nytimes.com/2017/08/01/technology/alkaline-batteries-replace-lithium-ion.html

Tech Guru Bill Joy Unveils a Battery to Challenge Lithium-Ion - Bloomberg

https://www.bloomberg.com/news/articles/2017-08-03/tech-guru-bill-joy-unveils-a-battery-to-challenge-lithium-ion

With the advent of lithium-ion batteries capable of outputting large capacity and relatively large voltage, the performance of various products mainly for home appliances has improved. However, lithium ion batteries require cobalt for their production,The problem of African children who are overwhelmed by cobalt miningHas been pointed out. Not only cobalt but lithium as a raw material is ubiquitous in the world, so we have risks in terms of stable supply. Then,Danger of explosion and flames on some smartphonesThere are also many problems in terms of safety, such as becoming clear.

Even if these disadvantages are subtracted, the high energy density of the lithium ion battery is attractive and it does not know where to spread, but from another viewpoint, the absence of a powerful battery replacing lithium ion , It can be said that it is in the background of lithium dependence, researchers all over the world are striving to develop a post · lithium ion battery.

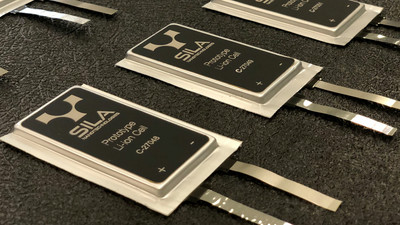

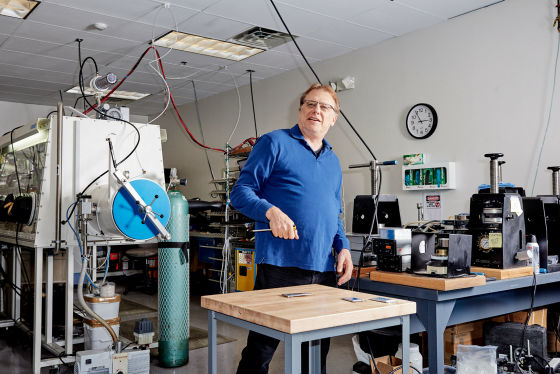

Ionic Materials, headquartered in Woburn, Massachusetts, USA, is developing an "alkaline polymer battery" with high energy density, to develop alkaline polymer battery manufacturing process that can replace energy storage technology including lithium ion battery I announced that I succeeded.

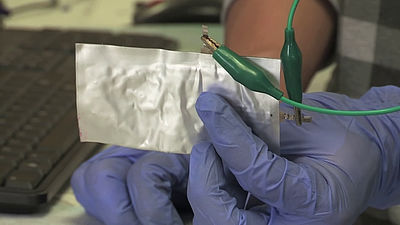

Conventional alkaline batteries are advantageous in that they can be manufactured cheaply and are excellent in terms of safety, but because of the disadvantage that they can not be charged, it is limited to be adopted as home appliances. However, alkaline batteries made from polymers developed by Ionic Materials are rechargeable secondary batteries, which is safe because no electrolyte is used, and it has already reached 400 charge / discharge cycles. Ionic Materials believes that performance can be further improved up to three times.

Regarding the method of manufacturing alkaline polymer batteries developed by Ionic Materials, it is revealed that "we have developed a manufacturing process that can be manufactured continuously like plastic wrapping", but technical details are not known. However, unlike lithium-ion batteries, they did not use cobalt, and they also succeeded in replacing commonly used alkaline batteries with cheaper aluminum than zinc used for electrodes. Ionic Materials responds to The New York Times that alkaline batteries using aluminum, a lightweight metal, are lighter and cheaper than common lithium ion batteries.

A powerful electric car as a power source for automobiles using clean energy requires a high performance battery. The Advanced Battery Consortium established in the American automobile industry has set a goal of drastically reducing the manufacturing cost of lithium ion batteries, but it is considered difficult to realize this with the extension of existing technologies. According to The New York Times, the manufacturing technology of alkaline batteries developed by Ionic Materials will realize energy production cost of less than 1/5 of the goal set by Advanced Battery Consortium.

Since Ionic Materials does not have manufacturing bases, we plan to negotiate with automobile manufacturers as a partner company that provides technology. Ionic Materials hopes to commercialize the manufacturing technology of alkaline polymer batteries that we have developed successfully this time within 5 years. Bloomberg New Energy Finance researches energy problems, "The full popularization of electric vehicles does not happen until 2025 when the cost necessary for driving coincides with the cost of automobiles with internal combustion engines such as gasoline, etc." Although we are making forecasts, it seems that the realization of high-performance and inexpensive batteries that replace lithium-ion batteries is at the forefront of full-scale diffusion of electric vehicles is a key.

Related Posts:

in Hardware, Posted by darkhorse_log