The contest "Amazon Picking Challenge" in which robots replace people and sort products is controlled by a sucker and a robot with two fingers

Currently it is mostly done by human hands Contest that makes robot able to act by judging items sorting work in the warehouse by themselves "Amazon Picking Challenge"The 2016 convention was held and this year the robot with two fingers and suckers won the victory and earned a prize of 50,000 dollars (about 5.1 million yen).

Amazon Picking Challenge

http://amazonpickingchallenge.org/

Sucking robot arm wins Amazon Picking Challenge - BBC News

http://www.bbc.com/news/technology-36702758

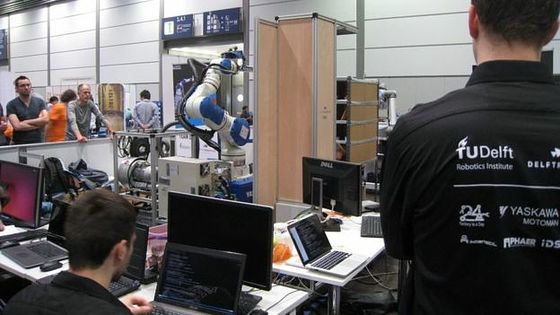

The team in the Netherlands controlled the competition that all 16 teams participated inDelftIt was a robot. JapaneseYaskawa Electric CorporationBased on the robot of YASKAWA, it is a system that combines hardware such as a camera for image recognition and a space recognition sensor using a laser and software that processes robots and processes them to quickly perform accurate work , And it has an excellent result with the performance which does without damaging the product.

In this contest held by Amazon who is developing the warehouse robot himself, competition for performance to perform precisely and promptly work on a given task is contested.It was held with 3 million yen prize money in 2015In this event, "Stow (storage)" operation of picking out the desired prize from the basket and putting it on the shelf ", and contrarily," Pick picking out the item on the shelf and taking it in the basket " (Take-off / picking) "Two tasks are given as tasks, and it is required that robots automatically recognize a number of prizes in any task and work accurately without human intervention.

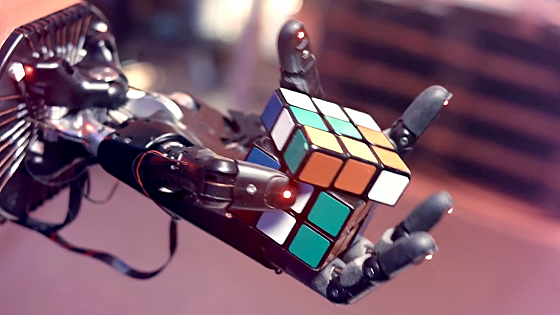

There are 40 items to be handled, each of which imitates items sold at Amazon. Therefore, the shape and weight, the hardness of the surface, etc are disagglomerated, it also included cloth products such as boxed DVD, bottled water, toothbrush and soft T-shirt inside. Delft's robot is equipped with a sucker that sucks the product at the end of the arm and two fingers that grab the item.

During competition, basically human operation is restricted only to the beginning, all product identification and movement work must be executed by the robot system. The team is given a rule that gives data describing the type of product to be targeted and the instruction of movement five minutes before the start of the game, and it is stipulated that it is impossible to hand out anything after the movement has actually started It is.

If the following failures occur during the competition, points are to be deducted.

· When some damage is given to the product

· When the product is dropped from a height of 30 cm or more

· When the item protrudes 0.5 cm beyond the specified position on the shelf

Kanter van Deurzen of the Delft team who controlled the competition said to the BBC 's interview "Because of the variety of products, we can not fight with only one method of grabbing products. In general warehouse work, A suction cup is attached and it is designed to suck the product, but in this competition it involves other things like T - shirts, boxes, and dumbbells, so another method was necessary, so one arm It was a very big challenge to grasp the placement of the products on which the products were placed and to move the products while preventing contact, "he said.

Delft's robot succeeded in almost completely accomplishing the task of Stow arranging items on shelves. In Pick's work to take out the item, we had a close battle with the team "PFN" who participated from Japan, but eventually we won the victory by 30 seconds earlier than the time we had to pick the first item ... apparently ...

It is hard to imagine that such robot technology will evolve in the future due to advancement of AI technology including space grasping, product recognition, work procedure judgment, etc. That's what I'm worried about is that "human work gone", van Deurzen of the Delft team said, "In the warehouse work, we still need people's hands from now on," . According to van Deurzen, although there are situations where robot technology has already realized more performance than what is generally considered, it is very difficult to create a system that can deal with all kinds of situations, Work by hand is indispensable. Future Prospects van Deurzen says, "It is probably impossible for a robot to do everything, but only 50% of it is a great advance, at that time human workers are needed for other tasks It will become like it will be. "

Related Posts: